The influence of addition of dried tomato pomace on the physical and sensory properties of whole grain rye flour cookies

Ivana S. Lončarević2, Jovana S. Petrović2, Aleksandar Z. Fišteš2

2University of Novi Sad, Faculty of Technology, Bulevar cara Lazara 1, 21000 Novi Sad, Serbia

ABSTRACT

One of the potential raw materials which could be used for production of food with added nutritional value is tomato pomace, a by-product from tomato processing. On the other hand, requirements of consumers for diverse food with potential for health benefits impose the need for creation of products made from different cereals. In this respect,the aim of this study was to evaluate the influence of addition of dried tomato pomace on the physical and sensory properties of whole grain rye flour cookies. The whole grain rye flour was substituted with tomato pomace powder in two levels (15% and 25%) in the standard formulation of short-dough cookie. The quality of final products was evaluated by instrumental and sensory methods. The results clearly demonstrated that redness (+a*) and yellowness (+b*) were highly influenced by level of tomato pomace in the cookie formulations due to its content of carotenoid pigments.The spread factor of the cookies made with addition of tomato pomace powder was higher than the control sample. Hardness of the cookie samples decreased for approximately 50% for the cookie sample with 25% tomato pomace level substitution when compared with control sample. According to the results of sensory analysis, substitution level of 15% caused decrease of surface roughness, fracturability, and granularity, as well as increase of caramel flavour intensity. Substitution level of 25% caused higher degree of cookie softening and more pronounced tomato flavour.Introduction

Tomato pomace, a by-product of industrial processing of tomato, comprise about 4-7% (w/w) of the total tomato processed into tomato products (Del Valle et al., 2006; Kalogeropoulos et al., 2012).Tomato pomace consists mostly of skin, seeds, and vascular tissue, containing up to 60% of dietary fibre per dry weight (Al-Wandawi et al., 1985; Del Valle et al., 2006; Lenucci et al., 2013). By-product of tomato processing is characterized by the high moisture content (about 80%), which makes it susceptible to microbiological contamination (Al-Wandawi et al., 1985; Lenucci et al., 2013).Drying process (convection or freeze drying) has been shown to be the most favourable pre-treatment for the preservation of fruit and vegetable processing industry by-products (O'Shea et al., 2012). Tomato pomace also represents a source of bioactive phytochemicals, such as lycopene, β-carotene and phenolic compounds, predominantly hydroxycinnamic acids and flavonols (Chanforan et al., 2012; Kalogeropoulos et al., 2012).

The insoluble-soluble fibre ratio in tomato pomace is 10:1, which makes these fibres more similar to those originating from cereals (García Herrera et al., 2010). In addition, tomato pomace proteins are rich in lysine, making it suitable for fortification of low-lysine foods, such as those based on cereals (Bajerska et al., 2015). Previous studies that dealt with the enrichment of cereal basedproduct with tomato pomace have included the enrichment of wheat bread (Majzoobi et al., 2011;Nour et al., 2015), rye bread (Bajerska et al., 2015), snack foods produced from extruded barley (Altan et al., 2008) and extruded durum wheat (Yağcı and Göğüş, 2008).

Increasing demands for the diverse foods with health benefits led to the use of different cereals inthe production of baking and confectionary products. These raw materials present a challenge for processing due to the fact that the proteins they contain are not of the same type and quality as those of wheat. Among these cereals, rye is commonly used for bread and ginger cookie production even though rye proteins are not capable of forming such continuous protein networks as wheat proteins can. Pentosans have the most prominent technological role in rye dough processing while dietary fibre and phenolic compounds contribute to the nutritional value of products (Hansen et al., 2002; Bondia-Pons et al., 2009). Furthermore, changes in rheological properties of rye dough have been associated with a decrease in water-holding properties of the dietary fibre (Hansen et al., 2002). Therefore, it was considered that water holding capacity of rye cookie dough could be improved by an addition of dried tomato pomace, which was previously shown to possess good water retention capacity (Belović et al., 2016).

Bearing in mind all mentioned above, the aim of this study was to examine the influence of the dried tomato pomace addition on the physical and sensory properties of whole grainrye flour cookies.

MATERIALS AND METHODS

Material and proximate composition analysis

In this study, whole grain rye flour (WGRF) purchased from the local supermarket was used as raw material for the cookies production. Tomato pomace prepared from local tomato variety was lyophilized in an industrial scale freeze-drier for 36 hours. Initial and final temperature of the material was -30°C and +37°C, respectively, while the pressure in the chamber varied from 5 x 10-2 to 7 x 10-3 mbar during lyophilisation. Lyophilized tomato pomace was ground in a coffee grinder (Gorenje, Velenje, Slovenia) in order to obtain a powder with particle diameter <150 µm, as determined by a rotational sieving machine (Bühler, Uzwil, Switzerland). Moisture, ash, sugars, starch, protein, fat, and dietary fibre content of whole grain rye flour (WGRF) and tomato pomace powder (TPP) were determined according to the standard methods (AOAC 2000).

Swelling coefficient and water retention capacity (WRC)

Swelling coefficient and water retention capacity (WRC) of whole grain rye flour – tomato pomace blends were determined using the methods described by Robertson et al. (2000) with some modifications. For the purpose of swelling coefficient and WRC determination, 3 g of rye flour – tomato pomace blends, placed in a closed centrifuge tube, were hydrated in 30 mL of distilled water at room temperature. Whole grain rye flour was used as a control sample. The bed volume occupied by the sample was recorded after equilibration (18 h). Swelling coefficient (SC) was calculated using the following equation:

After equilibration time (18 h), the samples were centrifuged (3,000 g; 20 min) (Eppendorf Centrifuge 5804 R, Hamburg, Germany). The supernatant was decanted and the solid residue was weighed. WRC was calculated using the following equation:

After equilibration time (18 h), the samples were centrifuged (3,000 g; 20 min) (Eppendorf Centrifuge 5804 R, Hamburg, Germany). The supernatant was decanted and the solid residue was weighed. WRC was calculated using the following equation:

Preparation of cookies

The cookie dough was prepared according to the following formula: whole grain rye flour/blendsof whole grain rye flour and tomato pomace powder (99.7 g), sugar powder (34.9 g), vegetable fat (20.9 g), sodium chloride (0.5 g), sodium bicarbonate (0.3 g), ammonium bicarbonate (0.2 g) and water (Pajin, 2009). Tomato pomace powder was used to replace part of the whole grain rye flour (15% and 25%) in applied cookie recipe. For cookie formulation with whole grain rye flour, water was added in order to achieve 18% of dough moisture. In the case of formulations with tomato pomace substitution, the content of added water was calculated on the basis of WRC of the blends. WGRF/blends, fat, and powdered sugar were firstly mixed thoroughly for 5.5 min. The remaining raw materials dissolved in distilled water were added and it was mixed for another 15 minutes. After resting (3 hours at 20 ºC, in thermostat), the dough was sheeted on a Laminoir Marchand LA4-500 to a uniform thickness of about 6 mm. The cookies were round shaped with a cutter of 45 mm diameter and baked on an aluminium tray at 230 ºC for 8.5-12.5 min. The cookie samples were then cooled down at room temperature for at least 30 min on the baking tray and finally packed into aluminium foiled pouches.

Colour, texture and spread factorof cookies

The colour of cookies was measured by a Chroma Meter CR-400 (Konica Minolta, Japan) on the top and bottom of the cookie surface. CIE L* (lightness), CIE a* (+a* = redness, -a* = greenness), and CIE b* (+b* = yellowness, -b* = blueness) were read using a D65 light source and the observer angle of 2°. The tristimulus values of CIE L*a*b* readings were calibrated against a standard white plate (Y=84.8; x=0.3199; y=0.3377). Colour readings in the centre of twelve cookies per batch were recorded, and the results were averaged. Textural analysis of cookies was conducted by using a TA.XTPlus Texture Analyzer (Stable Micro Systems, England, UK), equipped with a 3-point bending rig (HDP/3PB), and a 30 kg load cell. The test distance between the supports was 20 mm. Texture analyser settings were: mode – measure force in compression; pre-test speed – 1.0 mm/s; test speed – 3.0 mm/s; post-test speed – 10.0 mm/s; distance – 10.0 mm; trigger force – 50 g. Five measurements per each batch sample were made.

The spread factor (SF) was determined from the ratio of width (W) and thickness (T) of the cookie samples, according to the AACC methods (AACC, 1995). The average values of twelve determinations were reported.

All measurements were performed 1 h after baking, when cookies were cooled and stabilized. In addition, moisture content and texture were measured again after 24 h to get insight into changes during storage.

Sensory analysis

Six expert panellists from the Institute of Food Technology, aged 25-50 years,with sensory experience from sensory profiling work with different types ofbakery and confectionery products, participated in the study. Panellists were initially provided with sensory terms of cookie sensory profiles used in previously published research (Pajin, 2009) but were told that they could keep, delete or add any terms as appropriate during the training sessions. A consensus approach was used to allow further discussion on each sample and to define the descriptors (Table 1). Once the descriptors were established, all samples were evaluated by the panelusing an unstructured linear scale with the anchor points 0 – not perceptible and 100 – strongly perceptible (Meilgaard, et al. 2000). The evaluation was performed in tasting booths with controlled environment conditions (ISO, 2007).The samples were coded with three-digit numbers and presented to the panellists. Drinking water was provided for palate cleansing after each sample testing.

|

Property |

Descriptor |

Definition |

|

|

Appearance |

Shape uniformity |

Similarity between cookie and mould shape |

|

|

Colour uniformity |

Absence of differently coloured areas |

||

|

Surface roughness |

The amount of irregularity, bumps and cracks which can be seen on the surface of the cookie; smoothness is the absence of surface particles |

||

|

Odour |

Intensity |

Overall odour intensity |

|

|

Oral texture |

Hardness |

Force required to bite through |

|

|

Fracturability |

The force with which the sample breaks in crumbles |

||

|

Granularity |

The perception of rough particles during consumption |

||

|

Cohesiveness |

The degree of sample deformation before it ruptures |

||

|

Dissolving |

The degree of cookie dissolving in mouth after the 4-6 chews |

||

|

Moisture release |

Perception of water, measured by tactile means during consumption |

||

|

Flavour |

|

|

|

|

Olfactory sensations |

Tomato |

Aromatics or volatiles associated with tomato |

|

|

Caramel |

Aromatics or volatiles associated with caramelized sugar |

||

|

Taste sensations |

Sweet |

Basic taste produced by sugars such as sucrose, fructose, glucose, etc. |

|

|

Salty |

Basic taste produced by sodium salts, such as sodium chloride and sodium glutamate, and in part by other salts, such as potassium chloride |

||

|

Bitter |

Basic taste produced by substances such as quinine, caffeine, etc. |

||

|

Aftertaste |

Lingering taste in the mouth after swallowing a cookie |

||

Results and Discussion

The data of chemical properties of rye flour and tomato pomace are given in Table 2 calculated on the dry weight basis (dwb). The fibre and sugar content in the tomato pomace powder indicates a possible influence of these parameters on the physical and sensory characteristics of the final product, primarily in terms of the textural properties. Also, the amount of dietary fibre, especially insoluble fibre present in tomato pomace makes this raw material a suitable ingredient for creation of confectionery products with increased nutritional value (García Herrera et al., 2010; Navarro-González et al., 2011).

|

Parameter |

Whole grain rye flour |

Tomato pomace powder |

|

Moisture (%) |

10.37 |

3.05 |

|

Ash (% dwb) |

1.53 |

1.51 |

|

Total carbohydrates (% dwb) |

60.17 |

25.39 |

|

Sugars (% dwb) |

3.85 |

25.39 |

|

Dietary fibre (% dwb) |

12.94 |

62.04 |

|

Cellulose (% dwb) |

3.84 |

13.46 |

|

Total pectic substances (% dwb) |

- |

4.66 |

|

Protein (% dwb) |

12.39 |

3.53 |

|

Fat (% dwb) |

2.32 |

0.79 |

Data are presented as means of three replicates (n = 3).

The results presented in Table 3 clearly show that the addition of tomato pomace increased the swelling coefficient and water retention capacity as a result of the presence of a greater quantity of fibre provided by this raw material.

|

Parameter |

WGRF |

85WGRF:15 TPP |

75WGRF:25 TPP |

|

Swelling coefficient(SC) (mL/g) |

3.31 |

4.32 |

5.25 |

|

Water retention capacity (WRC) (g/g) |

1.11 |

1.31 |

1.43 |

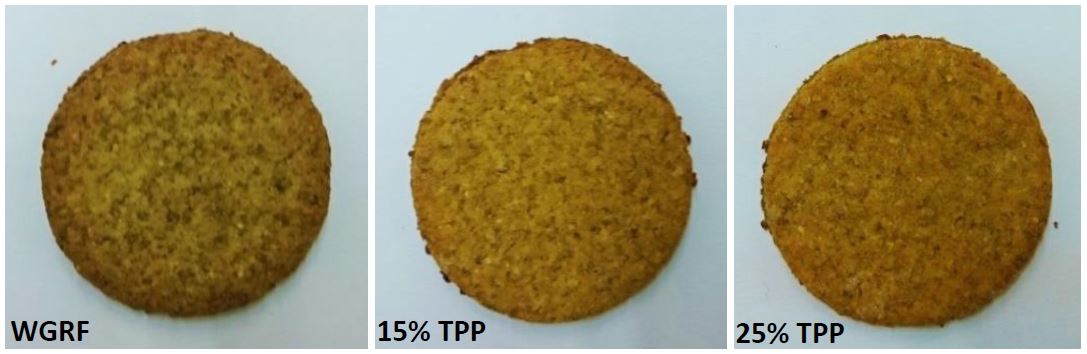

Regarding the colour measurements, the obtained results showed slight differences in the lightness values (Table 4). The increased levels of TPPsubstitution caused an increase in the colour coordinate values, such as redness and yellowness of the cookies, which can be also seen in Figure 1. This was expected due to the presence of red (lycopene) and orange (β-carotene) carotenoid pigments in the added TPP (Chanforan et al., 2012).

Figure 1. Cookies made of whole grain rye flour (WGRF) without and with tomato pomace powder (TPP) substitution (15% and 25%)

Figure 1. Cookies made of whole grain rye flour (WGRF) without and with tomato pomace powder (TPP) substitution (15% and 25%)There were differences among the tested samples in terms of moisture content, both after 1 h and 24 h (Table 4).The increase of TPP content in the cookie formulations caused thehigher levels of moisture content due to water binding properties of the used raw materials.The spread factor of cookies made with tomato pomace powder was higher than the control sample (Table 4) due to dissolution of higher amount of sugars, which occurred during the baking process (Gavrilović, 2000). Substitution of 15% and 25% of WGRF with TPP increased the sugar content by 84% and 140%, respectively.

|

Parameter |

WGRF |

85 WGRF:15 TPP |

75 WGRF:25 TPP |

|

L* |

56.94±0.86 |

56.48±0.56 |

55.37±0.86 |

|

a* |

8.04±0.48 |

11.27±0.39 |

12.73±0.39 |

|

b* |

26.02±0.48 |

35.23±0.63 |

38.12±0.74 |

|

Moisture after 1h (%) |

0.38±0.03 |

5.72±0.12 |

8.96±0.15 |

|

Moisture after 24h (%) |

0.85±0.05 |

5.22±0.09 |

8.38±0.07 |

|

Spread factor (W/T) |

7.3±0.5 |

9.3±0.3 |

9.9±0.2 |

Measurement of cookies texture one hour after baking showed that the hardness value decreased when pomace content in the formulation was increased. However, the results of texture obtained 24 h after baking showed slightly different trends (Figure 2). Namely, the control sample, and the sample with 15% TPP substitution showed increase of hardness, while the sample with 25% TPP substitution showed slight decrease.

Figure 3 shows the results of the sensory evaluation of the cookies. It could be noticed that there were no differences among the all samples regarding the shape and colour uniformity. The rated surface roughness was decreased with increase in TPP level, which could be explained by the higher amount of reducing sugars (Manohar and Rao, 1997). The greatest differences among samples were obtained for hardness, fracturability and granularity. Instrumental determination of hardness was in agreement with data obtained by sensory evaluation. The addition of TPP decreased the degree of cookie dissolving in mouth and sweet taste at the same time. By increasing the amount of tomato pomace, the intensity of tomato and caramel flavour increased, due to the aromatic taste characteristic for tomato pomace and caramelization of reducing sugars present in the raw material. In contrast to the expectations, the bitter taste was not perceived in all samples, although raw material contains higher amounts of tannins, which are known for its bitter taste (Soto-Vaca et al., 2012). The cookies with tomato pomace substitution level of 15% had smoother surface and less granular texture, as well as improved fracturability and more pronounced caramel flavour in comparison with control cookies. On the other hand, the cookies with tomato pomace substitution level of 25% were softer, with more pronounced tomato flavour when compared to both control cookies and cookies with 15% substitution level.

Conclusions

The obtained results indicate that the level of the tomato pomace powder in corporation changed various properties of the cookies, such us spread factor, hardness and colour of the cookie products. This study demonstrated the potential of using the studied tomato pomace portions in cookies production to achieve appropriate textural and sensory properties of the final product. According to the results of sensory analysis, substitution level of 15% caused decrease of surface roughness, fracturability, and granularity, as well as increase of caramel flavour intensity. Substitution level of 25% caused higher degree of cookie softening and more pronounced tomato flavour.

АCKNOWLEDGEMENTS

This paper is a result of the research within the project TR31007 financed by the Ministry of Education, Science and Technological Development, Republic of Serbia and the project 114-451-2085/2016 financed by the Provincial Secretariat for Science and Technological Development, Autonomous Province of Vojvodina, Republic of Serbia.

JOURNAL TOOLS

JOURNAL TOOLS

INSTITUTE

INSTITUTE