ESSENTIAL OIL COMPOSITION OF FRESH AND DRIED PEPPER FRUITS (Capsicum annuum L.)

DOI:

UDK:

JOURNAL No:

Volume 36, Issue 1-2

PAGES

29-34

KEYWORDS

Aldehydes, ground paprika, GC-MS, essential oil, postharvest treatment

Žarko S. Kevrešan1*, Nataša Č. Hrabovski2, Ksenija N. Kuhajda3, Neda Mimica-Dukić3, Marijana B. Sakač1

1 Institute for Food Technology, Bulevar cara Lazara 1, 21000 Novi Sad, Serbia 2 University of Novi Sad, Trg Dositeja Obradovića 5, 21000 Novi Sad 3 Faculty of sciences, department for chemistry, Trg Dositeja Obradovića 3, 21000 Novi Sad

ABSTRACT

Abstract

It is well known that color and pungency are the main quality parameters of ground paprika, but recently aroma of paprika spice has become a focus of investigation. The aim of this work was to determine changes in essential oil aldehyde composition of pepper fruits during processing. Pepper Cultivar “AlevaNK” for ground paprika production was used in this study. Sampling was done while fruits were in red stage of maturity. Sampled fruits were divided in four equal groups. The first group was used immediately for the analysis, the second group was kept for two days and then dried, while third and fourth groups were kept for 15 days to complete the postharvest treatments differeing in the presence of light. Twenty one aldehydes were identified, six of them were common to both fresh and dry samples (benzaldehyde, 2-nonenal, decanal, 2,4-decadienal tetradecanal and 9,17 octadecadienal), while a presence of hexanal made a difference between dried and postharvestly treated samples.INTRODUCTION

Pepper (Capsicum annuum L.) is one of the most significant vegetable plants in Western Balkans. Production of Spice paprika in the region of Pannonian plate has a long tradition. First printed manual for producing pepper fruits for ground papprika and for pepper fruits processing in Serbia was published at the begining of the XIX century (Ivković, 1933; Ivačković,1938). Pepper fruits are predominantly sold on market as a fresh fruits, but consumption of processed pepper fruits is also very significant. One of the very important products of pepper processing is ground paprika, a spice which is widely used trough the World. The main quality parameters for ground paprika products are the color and pungency (Carvajal et al., 1998; Govindarijan, 1986; Govindarijan et al., 1987), while aroma recently started to attract the attention of scientists (Mateo et al., 1997; Cremer and Eichner, 2000; Kocsis et al., 2002; 2003).

In the process of food production paprika is mainly used as a colorant. Unique red color of paprika is due to presence of capsantin and capsorubin, two carotenoids characteristic for the capsicum genus. Besides changing the color of the food, paprika also affect the flavor. During processing of Spanish paprika, pepper fruits are smoked during drying which gives them a specific aroma. Ground paprika aroma from Pannonian plate region consists only of naturally occurring compounds. According to Kocsis et al. (2002, 2003) chemical classes which can be found in ground paprika essential oil are: terpenes and their derivates, alcohols, aldehydes, ketones, acids, esters, benzene derivates, naphthalene skeleton compounds, hydrocarbons, sulphur compounds, phenolic compounds, nitrogen containing substances and carotenoid derivates. They have specific aroma, which can be sensed by humans in relatively low concentrations.

Having in mind development of tools for analysis of aromatic compounds (gas chromatography) and especially development of wide rage detectors on one hand and development of new analytical procedures for sample preparation on the other hand aim of this paper is to determine changes of aldehyde composition in essential oil during processing red pepper fruits in order to obtain paprika spice.

MATERIALS AND METHODS

Plant material

In this study pepper cultivar “AlevaNK” for paprika production is used. “Aleva NK” is relatively new cultivar and it is developed to solve problem of multiple fruit collection. As a result, ¾ of fruits are collected in the first harvest and ¼ in the second harvest. For this purpose pepper fruits were sampled from field intended for mercantile production. Pepper fruits were sampled in the stage of intensive red color. Sampled fruits were divided in four equal groups. First group was used immediately for analysis as fresh while the second group was left for two days and then dried in a laboratory dryer with fitted fan at 60±5 °C. Third and fourth group were left for 15 days for the postharvest treatment. Postharvest treatment was done in a glass-house under semicontrolled conditions, with a difference in light presence.. The third group was left in the dark and the fourth was exposed to natural sunlight. After the treatment fruits were dried, milled and obtained powder was used for the analyses.

Sample preparation

Essential oils were extracted by steam distillation from fresh and dry samples. Extraction was done from 100 g and 30 g of fresh and dried samples, respectively. Before extraction fresh, sample was cut in manageable pieces, and then homogenized with 500 ml of water, while dried samples were only mixed with same quantity of water before distillation. Due to the small amounts of essential oils, 1 ml of hexane was added to the samples. Distillation time was 90 minutes and obtained organic phase was collected and kept at -20 °C under inert atmosphere (N2) until further use.

Instrumentation

Separation of aldehydes from pepper fruit essential oils was done under following conditions:

- Instrument: Thermo Finnigan Trace GC – Trace MS

- Interface temperature: 280 °C

- Ion source temperature: 230 °C

- Carrier: He, flow: 1.5 ml min-1

- Injector: PTV Splitless, t=250 °C,

- Injected volume 1 µL

- Ion source: EI, 70 eV

Column and temperature settings for fresh pepper:

- Column: 30 m × 0,25 mm, PS 255, MEGA, Italy

- Film thickness: 0,25 μm

- Initial temperature: 50 °C

- Temperature program: linear, 4 °C minute-1

- Final temperature: 280 °C

Column and temperature settings for dry pepper:

- Column: 60 m × 0.25 mm, J&W DB, 5MS, Agilent, USA

- Film thickness: 0.25 μm

- Initial temperature: 50 °C

- Temperature program: linear, 2 °C minute-1

- Final temperature: 280 °C

Peaks were identified as aldehydes by comparison of their mass spectra with those in NIST data base (The NIST, 2001).

RESULTS AND DISCUSSION

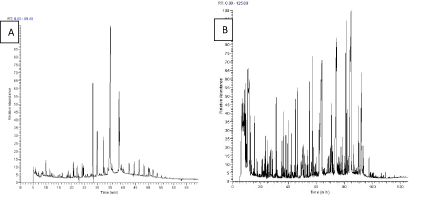

Essential oils typical chromatograms of fresh and dried pepper were shown in Figure 1.

Identified aldehydes in essential oils from fresh and dry paprika were shown in Table 1. In total, ten aldehydes were identified in fresh pepper. One of five dominant peaks in chromatogram of fresh pepper belongs to aldehyde hexadecanal.

Out of twenty aldehydes identified in essential oil of paprika, only six of them are common to both, fresh and ground paprika (benzaldehyde, 2-nonenal, decanal, 2,4-de-cadienal tetradecanal and 9,17-octadecadienal). Differences in aldehyde composition between fresh and dry pepper could be due to drying and other non enzymatic processes during heating of pepper fruits or from enzymatic process during homogenization of fresh sample. Enzymatic conversion system of formation of C6 aldehydes and alcohols from polyunsaturated fatty acids in disrupted pepper fruits was indicated by Wu and Liou (1986).

Out of twenty aldehydes identified in essential oil of paprika, only six of them are common to both, fresh and ground paprika (benzaldehyde, 2-nonenal, decanal, 2,4-de-cadienal tetradecanal and 9,17-octadecadienal). Differences in aldehyde composition between fresh and dry pepper could be due to drying and other non enzymatic processes during heating of pepper fruits or from enzymatic process during homogenization of fresh sample. Enzymatic conversion system of formation of C6 aldehydes and alcohols from polyunsaturated fatty acids in disrupted pepper fruits was indicated by Wu and Liou (1986).

Aldehydes composition of investigated ground paprika is very similar to Hungarian paprika (Kocsis et al., 2002; 2003). Common aldehydes for both types are: 2,4-hepta-dienal, benzaldehyde, octanal, 2-octenal, no-nanal and 2,6-nonadienal. Regarding the literature data, investigated dry pepper and Spanish paprika did not have any common alde-hydes (Mateo et al., 1997). In the study of a Zimmerman and Schieberle (2000) Moroccan and Hungarian paprika were compared and only two aldehydes were common, namely 2,4-heptadienal and 2,6-nonadienal.

Benzaldehyde was also identified in fresh bell peppers (Luning et al. 1994) and Japanese traditional pepper cultivar (Nakamura et al., 1999). According to Buttery et al. (1969) 2,6-nonadienal is one of three compounds characteristic for aroma of fresh green pepper. In our investigation, 2,6-nonadienal was not found in red, but is found in green pepper fruits (unpublished data).

Opposite to its presence in fresh and dried samples, identification of hexanal in fruits which were treated for 15 days (Table 1) indicates the occurance of the process of lipid oxidation during the postharvest period. Hexanal has low odor trashold (Guadagni et al., 1963; Eichner, 1973; Buttery et al., 1990) and it could contribute to aroma difference between postharvestly treated and dried sample.

Differences between our and literature data could be explained by geographical origin of paprika, drying conditions and pepper cultivars.

Table 1. Identified aldehydes in the essential oils of fresh and dried red pepper.

Aldehydes |

Fresh |

Dried |

15 days on dark |

15 days on light |

|

Benzaldehyde |

+ |

+ |

+ |

+ |

|

p- Methyl Benzaldehyde |

|

+ |

+ |

+ |

|

Hexanal |

|

|

+ |

+ |

|

2-Hexenal |

|

+ |

+ |

+ |

|

Heptanal |

|

+ |

+ |

+ |

|

2-Heptanal |

|

+ |

+ |

+ |

|

trans-2-Octenal |

|

+ |

+ |

+ |

|

2,6-Nonadienal |

+ |

|

|

|

|

Nonanal |

|

+ |

+ |

+ |

|

2-trans-6-cis-Nonadienal |

|

+ |

+ |

+ |

|

2-Nonenal |

+ |

+ |

+ |

+ |

|

Safranal |

|

+ |

+ |

+ |

|

Decanal |

+ |

+ |

+ |

+ |

|

2,4-Decadienal |

+ |

+ |

+ |

+ |

|

Tetradecanal (myristyl aldehyde) |

+ |

+ |

+ |

+ |

|

10-Undecanal |

+ |

|

|

|

|

Hexadecanal |

+ |

|

|

|

|

Pentadecanal |

|

+ |

+ |

+ |

|

Tetradecanal |

|

+ |

+ |

+ |

|

9,17-Oktadecadienal |

+ |

+ |

+ |

+ |

|

9-Octadecenal |

+ |

|

|

|

Mateo et al. (1997) and Zimmerman and Schieberle (2000) extracted volatiles from Spanish paprika with diethylether while Kocsis et al. (2002; 2003) extracted essential oils by steam distillation. Based on that, the sample preparation could be an argument for those differences.

CONCLUSION

Using steam distillation of fresh and dry samples of pepper followed by GC/MS separation and identification, 26 aldehyds were identified in AlevaNK cultivar. Referring to the obtained results, great difference between fresh and dry pepper samples exist, while only minor difference was observed between dry saples. Only six aldehydes were common to fresh and dried samples. The investigated cultivar has similar aldehyde compounds to Hungarian paprika, but non of the identified aldehydes were reported for Spanish paprika.

JOURNAL TOOLS

JOURNAL TOOLS

INSTITUTE

INSTITUTE