ABSTRACT

Abstract

Today, most often is a part of malt in the production of beer replaced with the nonmalted cereals: corn, wheat, rice or the crude barley itself. The aim is to obtain cheaper, more readily available product. Often appears the question, if the beer, obtained after replacing of malt with other cereals of the poorer quality than the all-malt beer. That question can not be answered easily. Surely, replacing the malt with other cereals product characterized with the identical quality can not be obtained. Such a beer will obviously have to some degree changed properties, and how will they be accepted, depends on a brewery skills and of consumers' preferences.

In this study as an adjunct for the barley malt in the production of brewers' wort the native triticale, variety NST 3/07 from the breeding experiments of the Institute of field- and vegetable crops from Novi Sad, was used. Triticale was grown at the Rimski Šančevi locality, in the year 2008. In the production of wort two series of the experiments were performed (with or without the addition of 1 μL of the enzyme with the activity of β-glucanase pro gramme of triticale. Triticale, variety NST, replaced 20, 40, 50 and 60 percents of barley malt in the grist. Experiments were performed on the laboratory level, using the infusion mashing procedure and the distilled water. The task was to investigate if with the additions of native triticale, variety NST 3/07, the worts with the quality that is satisfactory for beer production could be obtained, and how high is the maximal quantity of costly malt that can be replaced with the native triticale, without lowering of the quality of wort for the production of the light beer. With respect of extract content and wort color, the triticale variety NST 3/07 can replace up to 60 percent of barley malt in the production of light beer. With increasing of the triticale share in the grist, extract contents of worts and their viscosities were increased. The additions of commercial enzyme preparation decreased the viscosities and increased extract contents of the worts.

INTRODUCTION

Basic and starting raw material for the production of beer is brewers’ malt. Crude barley is not convenient for direct application in the technology of beer. It must be converted to barley malt. Accordingly, the beer technology can be divided on two mutually independent parts: malt technology, showing how to obtain malt from barley, and beer technology, showing the possibilities of beer production from malt and other war materials [Gaćeša, 1979]. Besides to malt, in beer production as the sources of extract other, non-malted raw materials, so called adjuncts, can be applied. They are used for the economical reasons – adjuncts are cheaper than malt; they can be used in the cases of shortages of barley and malt, as well as in the production of special types of beers, and for increasing of capacity of the brew house, and at the same time, of brewery as the whole.

In some countries, legal jurisdiction permits replacements of up to 40 percent of malt with the adjuncts. In our country, quantities of non-malted raw materials are not officially limited. The non-malted raw materials can be classified into two groups: (1) raw materials with starch as the basic extract source, including cereals and their processed forms (crude barley, corn, corn grists, wheat, rice, broken rice and similar; and (2) raw materials with sugar as the basic extract source. They are cane and beet sugar, barley and malt extract and special kinds of syrups [Grujić et al., 2007].

Triticale (Tritisecale) is the oldest artificially created hybrid cereal,, which was obtained by crossing of wheat (Triticum) and rye (Secale), so that its name was created by joining of the parts of these two words [Oelke et al., 1989]. Triticale is the cereal with high yields, extremely convenient as feed, being able to represent up to 35 percent of corn. In the mixtures with wheat flour, it enables manufacture of bread with a very good quality with a specific taste and flavor. In some countries triticale is used as an adjunct in the production of beer, because of lowering of costs of production. Investigations of the possibilities of application of triticale as a supplement for a part of malt in the brew house, it was concluded that the investigated triticale varieties (Pegaz and Orao) can replace up to 30 percent of malt without the increasing of viscosity and changes of the pH values [Ivić, 2006]. During the fermentation, carbohydrates fermentation was improved, and the final product was characterized with higher foam stability and lower polyphenols content, compared to all-malt beer. With the application of 25 percent of triticale wort viscosity was for 19 percent lower, and the filterability of beer was decreased for 10 percent [Glatthar et al., 2003]. From the nutritionists’ point of view depending of the crop, triticale has considerably better protein composition in comparison with wheat, and its amino acids composition is very favorable, similar to that of the wheat. For the comparison, the average protein content of triticale amounts to 14 percent (dry basis, DB), and that of winter barley – 13.2 percent (DB). The average ash content of triticale is 2.12% (DB), and of winter barley 2.47% (DB). The average crude fat contents of the two cultures are similar, being 1.5 to 1.7% (DB). The average cellulose content of triticale amounts to 2.8% (DB), and of winter barley –about 5% (DB). The analysis of variance showed great effect of the year of production on the protein-, fats- and ash contents, while the effect of the variety was negligible [Mastilović, Filipčev, 2005]. The very significant characteristic of the triticale is that it possesses its own enzymes for the starch degradation, what considerably cuts down the production costs, while the application of technical enzymes for the degradation of the triticale starch is not necessary. Moreover, some varieties of triticale have surplus quantities of amylases that can be utilized for the saccharification of other raw materials. Besides to the amylolytic enzymes, triticale contains the proteolytic enzymes as well, what is important for the degradation of kernel [Oelke, 1989]. The temperature optimum of the triticale amylases it between 55 and 60 ºC. The relatively low temperature optimum for the breakdown of the triticale starches compared with other cereal starches represents the great advantage, as it depresses costs of heating of starch slurries during the mashing [Vučurović, 2007]. The selection with the cross-breeding enabled the coupling of the positive characterristics of several species in the new plant. The selection by cross-breeding needs knowledge of the heredity laws, of features of the parent varieties used for crossing and of goals that due to crossing could be achieved. Contemporary cultivars are obtained by the multiple crossings. Such a procedure enables in a shorter period of time to synthesize in a single cultivar the parameters of yield, quality, resistance to diseases from several parent varieties [Schuster et al., 1999].

MATERIALS AND METHODS

In this work, as the supplement of the barley malt for the production of wort aimed for beer production, the native triticale, variety NST 3/07 was used. It was used in such a way, as to replace 20, 40, 50 and 60 percent of barley malt with the native triticale in other to find out how high its share could be, to express the negative effects with respect to the quality parameters of the brewers’ wort. Mashings were performed with and without application of the commercial enzyme preparation with the β-glucanase activity. Experiments were performed in the laboratory scale. For the experiments, as the raw materials were used: (1) the distilled water, (2) barley malt, (3) native triticale, variety NST 3/07, (4) the yeast Saccharomyces uvarum, strain 112 from the collection of Faculty of Technology of Novi Sad, (5) Utltraflo max, the enzyme with the β-glucanase activity (Novozymes, Denmark), in the quantity of 1 μL/g of triticale. The analyses of raw materials and of the obtained worts were performed by standard brewer’s method of analyses [MEBAK, 1993].

Table 1. Malt analysis

Parameter |

Value

|

|

Moisture content, %

|

4.81

|

|

Extract content, fine grind, % DB

|

78.84

|

- saccharification time, minutes

|

do 10

|

|

|

clear

|

|

|

2.5

|

|

|

11

|

|

|

5.32

|

- soluble nitrogen mg/100 mL

|

79.80

|

|

|

0.71

|

|

|

1.503

|

- formol nitrogen, mg/100 mL

|

51.62

|

|

Extract content, coarse grind, % DB

|

76.78

|

|

Extract difference, % DB

|

2.06

|

|

Hartong VZ 45ºC, %

|

38.51

|

|

Kolbach index, %

|

40.38

|

|

Attenuation degree, real, %

|

54.27

|

|

Attenuation degree, apparent, %

|

64.33

|

Analytical parameters for the applied malt- and triticale samples are outlined in the Tables 1 and 2 respectively. Malt sample was obtained from one of Serbian malting plants, and the triticale sample was the variety NST 3/07, crop 2008, from the experimental field in Rimski Šančevi of The Scientific Institute of field and vegetable crops of Novi Sad, Serbia.

Table 2.

Analyses of the triticale used as an adjunct

|

Parameter

|

Value

|

|

Extract content, as is, %

|

71.21

|

|

Extract content % DB

|

78.66

|

- saccharification time, minutes

|

15-20

|

|

|

clear

|

|

|

3.0

|

- rate of filtration, minutes

|

11

|

|

|

5.23

|

- soluble nitrogen mg/100 mL

|

66.15

|

|

|

1.747

|

- formol nitrogen, mg/100 mL

|

46.38

|

|

Attenuation degree, real, %

|

52.46

|

|

Attenuation degree, apparent, %

|

64.91

|

Mashings were performed by the infusion mashing procedure, with the replacements of 0 (control), 10, 40, 50 and 60 percent of barley malt with triticale, with or without addition of the commercial enzyme preparation possessing the β-glucanase activity. Mashings were done in the bath form determination of extract. The basis for calculation was the extract content of malt on the „as is“ basis. In the control sample, 50 grams of barley malt flour (fine grist) were mashed in, with 50 ml of the distilled water. After completing of mashing, mashes were filled up to the total weight of 450 grams.

For the calculation of additions of the triticale flour quantities instead of barley flour, the following material balance equation was used:

Emalt, as is∙ mmalt = Etriticale, as is ∙ mtriticale

Or concretely, each gram of malt from the sample was replaced with 1.054 grams of triticale, so that the calculated extract contents in all mashes were the same.

The mashing procedures were as follows: Quantities of fine grounded malt and triticale flours, equivalent to totally 50 gram of malt flour, were mashed-in with 200 mL of the distilled water at 45 – 46 ºC. After homogenization with the glass rod, beakers with mashes were placed in the pre-heated mashing bath at 45 ºC, and after 30 minutes of rest at that temperature (with mixing; mixer speed 200 rpm), the whole mash was heated up to 70 ºC in 25 minutes. Mash was then saccharified at that temperature for 1 hour, with continuous mixing. After that, mashes were cooled down to about 20 ºC in 10 – 15 minutes by introducing the tap water into the bath. After cooling, beaker contents were filled p with the distilled water. The mashes were filtered and the obtained worts were the analyzed.

The following analyses for all obtained mashes, i.e. worts were performed: extract content by pycnometer, saccharification time, filtration rate, wort clarity, wort color, wort pH value, wort viscosity, soluble nitrogen content, formol nitrogen content, real and apparent attenuation degree.

Two series of experiments were performed. Series 1 – mashings of mixtures of malt – and triticale flours; series 2 – mashing of equivalent mixtures of malt- and triticale flours with the additions of the enzyme preparation Ultraflo max in the quantities corresponding to 1 μL/g of triticale flour.

RESULTS AND DISCUSSION

Results of the analyses obtained during mashings and of the clarified worts without the enzyme additions and with the enzyme additions are shown in the Tables 3 and 4, respectively.

Table 3. Analyses of mashes and worts obtained with triticale flour as an adjunct, without the additions of the enzyme preparations

Parameter |

Share of triticale flour in grist, %

|

|

0%

|

20%

|

40%

|

50%

|

60%

|

|

Extract content, % w/w.

|

8.529

|

8.519

|

8.592

|

8.585

|

8.572

|

|

Saccharification time, minutes

|

do 10

|

10-15

|

10-15

|

10-15

|

10-15

|

|

Wort clarity

|

clear

|

clear

|

clear

|

clear

|

clear

|

|

Wort color, EBC units

|

2.5

|

3.0

|

3.0

|

3.0

|

3.0

|

|

Filtration rate, minutes

|

11

|

13

|

11

|

9

|

9

|

|

pH value

|

5.32

|

5.14

|

5.24

|

5.33

|

5.47

|

|

Soluble nitrogen, mg/100mL

|

79.80

|

65.80

|

63.70

|

63.70

|

60.90

|

|

Viscosity, mPa·s, 8.6%e

|

1.503

|

1.574

|

1.710

|

1.758

|

1.833

|

|

Formol nitrogen, mg/100mL

|

51.62

|

45.50

|

47.25

|

48.13

|

49.00

|

|

Real attenuation, %

|

54.27

|

53.63

|

59.26

|

51.47

|

51.08

|

|

Apparent attenuation, %

|

64.33

|

66.38

|

73.17

|

63.62

|

63.09

|

When replacing a part of malt flour with the triticale NST 3/07 flour without the enzyme preparation (Table 3), characteristic parameter values compared with the values for the control wort are changed in the following manner. Extract contents in worts with 40, 50 and 50 percent of triticale flour were increased, while that of the wort with 20 percent of triticale flour was only slightly decreased. Saccharification time for samples with triticale flour content of up to 60 percent was 10-15 minutes, being slightly higher than for control mash. Indicating on the adequate quantities of the amylolytic enzymes in the triticale flour. Wort clarities with the increased quantities of the triticale flour remained unchanged, remaining clear like the control wort. Wort colors were slightly increased (from 2.5 to 3 EBC units). Filtration rates were not significantly changed with the increasing of triticale flour shares. pH value dropped in the wort with 20 percent of triticale flour, and then gradually growed up for greater triticale flours contents. Viscosities of wort, with the increased triticale flour contents gradually increased, and shares of the soluble nitrogen contents of worts generally showed tendency to be lower. Attenuations (real and apparent) were the highest in the wort for 40 percent of the triticale flour, and after that they gradually decreased.

Table 4. Analyses of mashes and worts obtained with triticale flour as an adjunct, with the additions of the enzyme preparations

|

Parameter

|

Share of triticale flour in grist, %

|

|

0%

|

20%

|

40%

|

50%

|

60%

|

|

Extract content, % w/w.

|

8.529

|

8.623

|

8.659

|

8.751

|

9.551

|

|

Saccharification time, minutes

|

do 10

|

do 10

|

do 10

|

do 10

|

do 10

|

|

Wort clarity

|

clear

|

clear

|

clear

|

clear

|

clear

|

|

Wort color, EBC units

|

2.5

|

3.0

|

3.0

|

3.0

|

3.0

|

|

Filtration rate, minutes

|

11.0

|

9.5

|

10

|

10

|

10

|

|

pH value

|

5.32

|

5.29

|

5.38

|

5.44

|

5.45

|

|

Soluble nitrogen, mg/100mL

|

79.80

|

51.80

|

62.30

|

63.00

|

70.70

|

|

Viscosity, mPa·s, 8.6%e

|

1.503

|

1.473

|

1.489

|

1.510

|

1.487

|

|

Formol nitrogen, mg/100mL

|

51.62

|

43.75

|

44.63

|

45.50

|

47.25

|

|

Real attenuation, %

|

54.27

|

57.09

|

57.62

|

59.20

|

55.92

|

|

Apparent attenuation, %

|

64.33

|

70.61

|

71.32

|

73.08

|

68.95

|

In the similar experiments, but the additions of the enzyme preparation with the β-glucanase activity (table 4), the corresponding changes of parameters were as follows. If compared with the control wort, extract contents were gradually increased with the increasing of the native triticale flour content. Saccharification time was unchanged and remained less than 10 minutes. Wort clarities also remained unchanged, pH values at 20 percent supplement was lower and than showed the tendency of increasing. All wort viscosities were lower than those of control wort, with the exception of that for wort with 50 percent of native triticale flour, which was insignificantly above the value for the control wort. Soluble nitrogen content showed the tendency of increasing with the increasing of shares of the native triticale flour. Attenuations were significantly increased for worts with up to 50 percent of triticale flour, and after that they were decreased.

Comparative results for worts obtained without and with application of the commercial enzyme preparation.

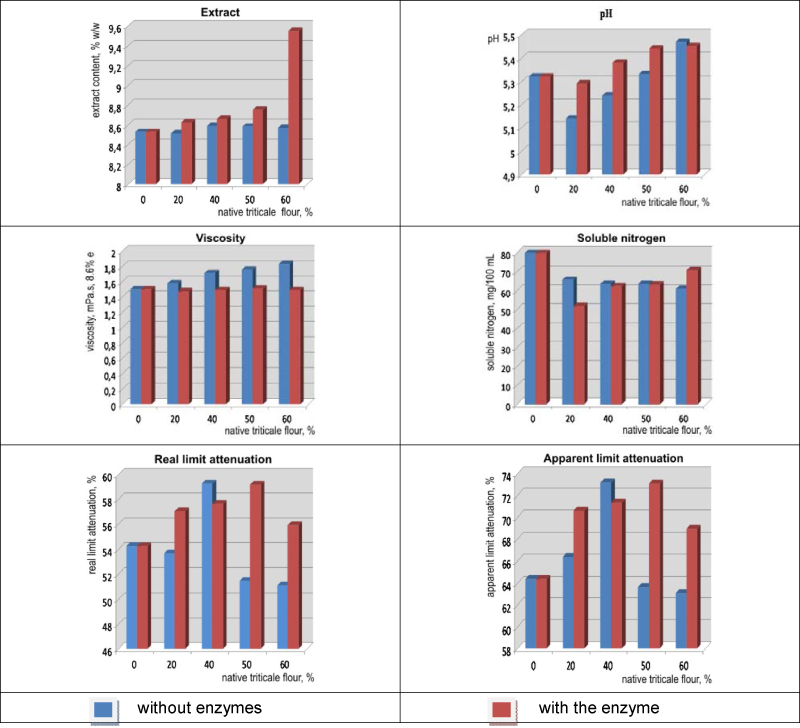

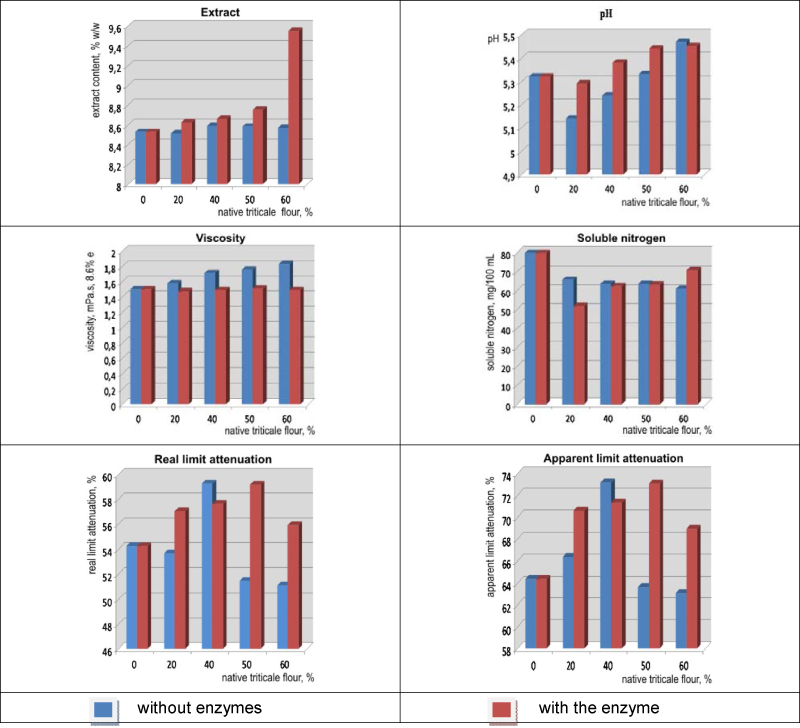

Fig. 1 shows comparative results for the extract contents, pH values, viscosities, soluble nitrogen contents real and apparent attenuations of worts depending on the share of the triticale flour with or without commercial enzyme preparation additions. From the Fig 1 it is seen that the extract contents in the worts were significantly higher for the same triticale flour shares, for the samples with the addition of the enzyme preparation. For the light malt, pH value should be within the limits of 5,5 to 6,0 [JUS, 1997]. All the worts, with or without the enzyme preparations, showed the increased pH values at the increased triticale flour shares, but these changes should not be considered as significant. High viscosities of worts obtained without the enzyme preparation additions indicate that triticale, most probably, has not the adequate activity of the endo-β-glucanase, so that the cytolytic degradation was not adequate. When the commercial enzyme was used, viscosities were considerably lower than those without the enzyme, and they were within the limits for a good brewers’ wort. Values for the soluble nitrogen were decreasing with the increasing of the triticale flour shares without the enzyme, but they after the addition of the enzyme, the tendencies showed to be opposite. Interesting is, that the absolute quantities of the soluble nitrogen were higher in the comparable worts without the enzyme than in the worts with the enzyme, with exception of the worts obtained from grists containing 60 percent of triticale. The results for attenuations given in the Fig. 1 also showed that the attenuations were higher for the worts with the enzyme preparation Ultraflo max addition, with the exception of those for the supplementation rate of 40 percent. Tendencies for real and the apparent attenuation degrees were, of course, similar.

Fig. 1. Comparative representation of the results for worts obtained with different triticale flour shares with and without the additions of the enzyme preparation Ultraflo max.

CONCLUSION

On the basis of the obtained results, the following conclusion can be made:

The native triticale NST 3/07 could be possibly used as an adjunct for brewing purposes, owing to its extract contents, with supplementations of barley malt as high as 60 percent. Mashes produced from grists with different shares of the triticale flour have good saccharification times of 10 – 15 minutes, what means that the starch degradation is fast, i.e. that the amylolytic enzymes activities are satisfactory. Wort color is not changed with the increased shares of the triticale flour, being 3 EBC units, so that this triticale variety can be applied in the production of light beers. Wort viscosity shows a tendency of increasing with increasing of the native triticale flour, and at the share of 40 percent and above, the viscosity is considerably higher than tat of the control wort.

Wort produced from grists with different native triticale contents and with the addition of commercial enzyme preparation Ultraflo max, has saccharification time below 10 minutes for all examined triticale flour shares, indicating very good degradation of starch and faster saccharification of mash with the addition of the enzyme. Viscosities of the worts produced with the enzyme additions, while the introduced β-glucanase degrades the hemicelluloses and gummous substances present in the triticale flour (as well as those of the malt) to the degradation products with lower molecular weights and lower viscosities.

With respect to the extract content and wort color, triticale variety NST 3/07 can be used as a substitute of a part of barley malt for the production of light beer, with the shares as high as 60 percent. The increased triticale shares in grists cause increased extract yield (positive), and increased viscosity (negative) of the wort. The addition of the enzyme with β-glucanase activity causes further increasing of the extract content and the elimination of the bad consequences of the increased values of viscosity.

Download full article PDF

DOWNLOAD PDF

DOWNLOAD PDF

JOURNAL TOOLS

JOURNAL TOOLS

INSTITUTE

INSTITUTE