Drying characteristics of traditional fermented sausage Petrovská klobása - the effect of different ripening conditions and use of starter culture

2University of Novi Sad, Faculty of Technology, Bulevar cara Lazara 1, 21000 Novi Sad, Serbia

ABSTRACT

A study was carried out on traditional Serbian dry-fermented sausage Petrovská klobása in order to investigate the effect of different ripening conditions and use of starter culture (SC) on drying characteristics of this typical meat product. The results related with reduction of diameter, water activity (aw) and moisture content of sausages, obtained during ripening, indicated 30 days faster drying process in controlled industrial ripening room (RR) than in traditional room (TR) (60 vs. 90 days). Along with the ambient (thermo-hygrometric) conditions, this phenomenon was also determined by pH, which was lower in RR sausages (P<0.05), especially in those made with SC. High values of coefficient of determination (r2>0.992) indicate good fit of the experimental data (average moisture content vs. drying time) using third degree polynomial equation, both for RR and TR sausages, whether the samples were produced with or without SC. Additionally, the evolution of moisture content ratio between internal and external fractions of sausages indicated more intense drying in the external ones. This was particularly pronounced in sausages made with SC after 30 days of drying. The use of SC and RR in processing of Petrovská klobása seems to be a potential technological improvement to shorten the drying period and to prolong the production season of this traditional meat product.INTRODUCTION

Drying and fermentation of meat products are probably the most ancient ways of preservation known to man. Hence, natural dry-fermented sausages have 2000 years long tradition of originating in China and the Mediterranean area. During drying water is removed from the product, aw is reduced, and consequently the growth of microorganisms is inhibited. Moreover, fermentation achieved by naturally present or by added lactic acid bacteria (LAB) results in acid production which has a positive effect on safety, sensory characteristics and shelf life of sausages (Comi et al., 2005; Petäjä-Kanninen and Puolanne, 2007; Zukál and Incze, 2010).One could say that there are almost as many types of traditional sausages as geographical areas and producers. The clear regional differences are recognizable although each production is based on a combination of drying and fermentation. In Mediterranean countries, France, Hungary and Balkan countries, air-dried, spicy sausages predominate, while in Northern and Central Europe most of the fermented sausages are smoked, and drying is less intensive (Lücke, 1998; Vignolo et al., 2010).

However, each traditional/artisanal production process is very time consuming. Thus, shortening of drying and ripening period would result in a reduction of the drying facilities, storage time, capital and labour, and would increase the profit margin and competitiveness of the product. The drying rate can be sped up by increasing the temperature and reducing the air relative humidity, while bacterial starter cultures (composed of selected LAB and Gram-positive catalase positive cocci) are widely used to accelerate the fermentation and ripening process, as well as to improve the quality and safety of the final product (Lücke, 1998; Fernandez et al., 2000; Arnau et al., 2007; Talon et al., 2008; Cocconcelli, 2010).

Petrovská klobása is a dry-fermented sausage manufactured in municipality of Bački Petrovac (Province of Vojvodina, Northern Serbia). Due to its production (smoking, intensive drying) and sensory characteristics (aromatic and spicy-hot taste, dark red colour and hard consistency) it represents a transitional type between the two basic types of the European fermented sausages listed above. Petrovská klobása is a part of Slovaks’ heritage, who inhabited Vojvodina in 18th century, and who are still producing it in traditional manner according to original recipe of their ancestors, without use of chemical additives and microbial starters. In small household enterprises this sausage is made during winter (usually December), when temperatures are around 0°C or lower. Thus, it undergoes slow drying and ripening processes (90 days at least) (Ikonić et al., 2011; 2012; 2013; Tasić et al., 2012).

In order to investigate the possibility of Petrovská klobása production outside the usual season, drying characteristics of sausages, prepared with or without starter culture and dried/ripened in different thermo-hygrometric conditions (traditional room vs. controlled ripening room), were determined in this study.

MATERIAL AND METHODS

Sausage preparation

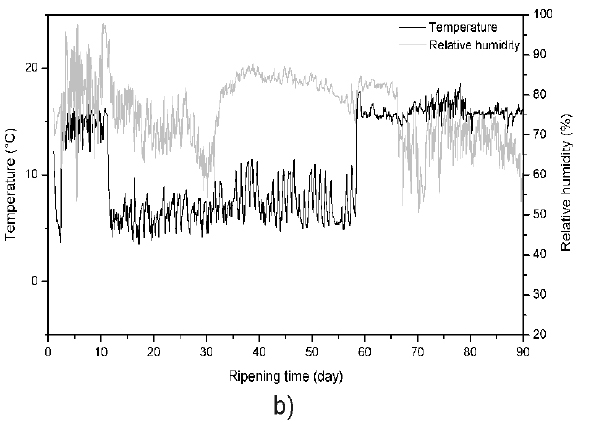

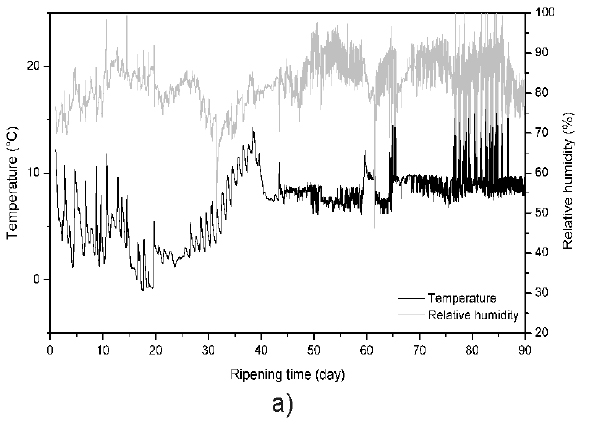

Petrovská klobása sausages were manufactured from a mixture of lean minced pork (80%) and pig back fat (20%). After grinding the meat and the back fat (about 10 mm sized), raw materials were mixed with seasonings (red hot paprika powder, salt, raw garlic paste, caraway and crystal sugar) until a homogeneous composition was achieved. Half of obtained meat/fat mixture was inoculated with 0,015% of starter culture (Quick-starter, Lay, Gewirze OHG, Germany) containing Lactobacillus sakei (25%), Pediococcus pentosaceus (25%), Staphylococcus carnosus (25%) and Staphylococcus xylosus (25%). The seasoned batter was immediately stuffed in collagen casings (500 mm long and 55 mm in diameter) and raw sausages, with and without starter culture, were ripened in different environments, a traditional room (TR) and a controlled industrial ripening room (RR). The ambient conditions in TR were characterised by low air temperature (average 7.11 ± 3.20°C) and high relative humidity (RH) (average 82.6 ± 5.98%) (Figure 1(a)). Figure 1. Environmental (thermo-hygrometric) conditions recorded during drying/ripening in traditional room (TR) (a) and controlled industrial ripening room (RR) (b)

Figure 1. Environmental (thermo-hygrometric) conditions recorded during drying/ripening in traditional room (TR) (a) and controlled industrial ripening room (RR) (b)Samples

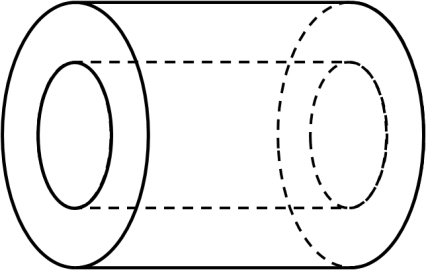

Samples taken at distinct processing stages, included raw meat/fat mixture prior to stuffing (0) and three randomly selected sausages after 2, 6, 15, 30, 60, and 90 days of drying. Physico-chemical analyses were carried out at these sampling times. In order to determine moisture content in central and peripheral layer, each sausage was subdivided in two concentric fractions, the more internal one with 25.4 mm in diameter and the external circular crown with the rest to full diameter of sausage (Figure 2). Therefore, three samples were obtained from each sausage (whole sausage and two fractions representing radial samples) which were independently homogenized prior to moisture content analysis.Physico-chemical analysis

In order to determine diameter reduction, two measures were taken at each sample sausage at the beginning and after previously mentioned periods of the drying process. The difference in diameter, expressed as percentage of the initial measure, represents the value of diameter reduction (%). Water activity (aw) of samples was determined using Testo 650 measuring instrument with a pressure-tight precision humidity probe (Testo AG, USA). The pH was measured using the portable pH meter Testo 205 (Testo AG, USA) equipped with a combined penetration tip with temperature probe. Moisture content was determined by drying the samples at 103 ± 2 °C to constant weight (ISO 1442:1997).Modeling drying kinetics

The experimental data obtained for the moisture content versus time (known as the batch drying curve) was fitted to cubic polynomial, as suggested by Kemp et al. (2001) and Guiné (2005), in the form:

where M is the dry basis moisture content and t is the drying time in days.

The adequacy of the models has been evaluated by the coefficient of determination (r2), which should be close to one.

Statistical analysis

Statistical analysis was performed using Statistica 10.1 software (StatSoft, Tulsa, Oklahoma, USA). One way (ANOVA), Post-hoc (Duncan test) was performed to compare the means of pH and aw values of samples. Differences were considered significant at P<0.05.

RESULTS AND DISCUSSION

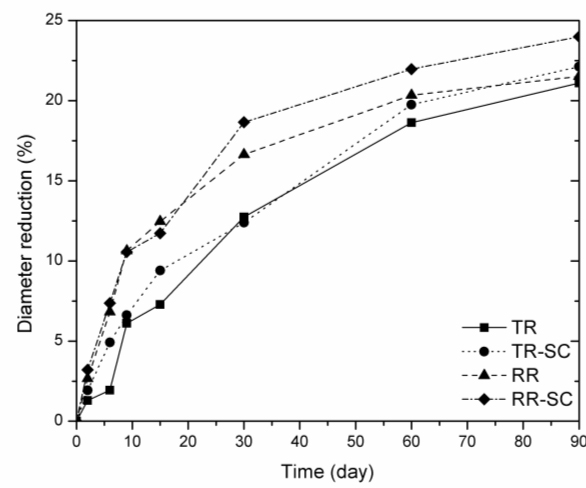

Figure 3. shows the diameter reduction (%) during drying and ripening of Petrovská klobása. The highest percent of diameter reduction after 90 days of drying was registered for RR sausages inoculated with starter culture (RR-SC), amounting 24.0%. On the contrary, at the same processing stage, naturally fermented TR sausages had the lowest value of this parameter (21.1%). Obviously, processing time, addition of starter culture and different thermo-hygrometric conditions significantly (P<0.05) affected shrinkage of sausages, mostly reflected as diameter reduction. At the very beginning of processing, during meat grinding and mincing procedures, the added salt promotes the solubilization and extraction of proteins from the myofibrils, forming a sticky protein film around the minced particles. Subsequently, due to fermentation process pH drops, and consequently the solubilized proteins aggregate and form a strong gel that binds the fat and meat closely together. Moreover, when the isoelectric point of major muscle proteins (myofibrillar) is reached (pH≈5.0) water holding capacity is the lowest and it can be easily exudated from the muscle fibers and evaporated. Thus, both gel formation (condensation structure) and water evaporation, caused by syneresis and drying, result in the shrinkage of sausages which is reflected in a significant diameter reduction (Katsaras and Budras, 1992; Barbut, 2007; Huff-Lonergan, 2010). This process was particularly pronounced in RR-SC sausages, where the higher initial temperature (Figure 1(b)) and LAB addition caused rapid and intensive pH drop (Table 1), and consequently easier dehydration and homogenisation of sausage. Figure 3. Diameter reduction (%) during drying/ripening of non-inoculated and starter-inoculated (SC) Petrovská klobása sausages in traditional room (TR) and controlled industrial ripening room (RR)

Figure 3. Diameter reduction (%) during drying/ripening of non-inoculated and starter-inoculated (SC) Petrovská klobása sausages in traditional room (TR) and controlled industrial ripening room (RR)Further, sausages produced under different thermo-hygrometric conditions presented close aw values for the same drying and ripening periods analysed, with differences being noticeable (P<0.05) after 30, 60 and 90 days of processing, when aw values were significantly lower in RR sausages. This phenomenon was mainly the consequence of different air temperature and relative humidity conditions used in the respective drying/ripening operations, as the differences registered between non-inoculated and starter-inoculated sausages were not significant (P>0.05). After 90 days of drying, water activity ranged (P<0.05) between 0.86 and 0.81, in TR and RR sausages, respectively. This data indicate very intensive drying process in industrial ripening room, which was actually finished 30 days earlier, when aw registered in RR sausages was 0.87 (Table 1). These aw values (0.86-0.87) corresponded with good sensory properties of Petrovská klobása (data not shown) and were in agreement with those generally found in a number of European dry-fermented sausages (Franco et al., 2002; Di Cagno et al., 2008; Talon et al., 2008; Spaziani et al., 2009).

Sample |

Parameter |

Time (day) |

|||||||

|

0 |

2 |

6 |

9 |

15 |

30 |

60 |

90 |

||

|

TR |

pH |

5.55ab,A ±0.03 |

5.54ab,A ±0.03 |

5.58b,A ±0.05 |

5.51a,D ±0.03 |

5.26e,D ±0.03 |

5.04c,C ±0.04 |

5.03c,B ±0.03 |

5.15d,A ±0.03 |

|

aw |

0.97a,A ±0.01 |

0.97a,B ±0.01 |

0.97a,B ±0.00 |

0.96b,B ±0.00 |

0.95b,A ±0.01 |

0.93e,B ±0.01 |

0.90d,B ±0.01 |

0.86c,B ±0.00 |

|

|

TR-SC |

pH |

5.55a,A ±0.03 |

5.57a,A ±0.03 |

5.55a,A ±0.03 |

5.35a,A ±0.04e,C |

5.08b,C ±0.05 |

4.93c,A ±0.04 |

4.99d,A ±0.03 |

5.12b,A ±0.03 |

|

aw |

0.97d,A ±0.00 |

0.97cd,AB ±0.00 |

0.96bc,A ±0.00 |

0.96b,AB ±0.01 |

0.94a,A ±0.00 |

0.94a,B ±0.01 |

0.90f,B ±0.01 |

0.86e,B ±0.00 |

|

|

RR |

pH |

5.55c,A ±0.03 |

5.55c,A ±0.01 |

4.99d,C ±0.02 |

4.87a,B ±0.06 |

4.89ab,B ±0.05 |

4.93b,A ±0.02 |

5.09e,C ±0.04 |

5.22f,B ±0.03 |

|

aw |

0.97c,A ±0.01 |

0.97bc,AB ±0.00 |

0.96ab,A ±0.01 |

0.95a,AB ±0.00 |

0.94g,A ±0.00 |

0.92f,A ±0.01 |

0.87e,A ±0.09 |

0.81d,A ±0.01 |

|

|

RR-SC |

pH |

5.55b,A ±0.03 |

5.55b,A ±0.03 |

4.80c,B ±0.05 |

4.75a,A ±0.04 |

4.76a,A ±0,04 |

4.85d,B ±0.02 |

4.96e,A ±0.02 |

5.16f,A ±0.01 |

|

aw |

0.97g,A ±0.00 |

0.96b,A ±0.00 |

0.95ab,A ±0.01 |

0.95a,A ±0.00 |

0.94f,A ±0.01 |

0.91e,A ±0.00 |

0.87d,A ±0.00 |

0.81c,A ±0.01 |

|

a-g Means within the same row with different superscript letters are different (P < 0.05)

A-D Means within the same column with different superscript letters are different (P < 0.05)

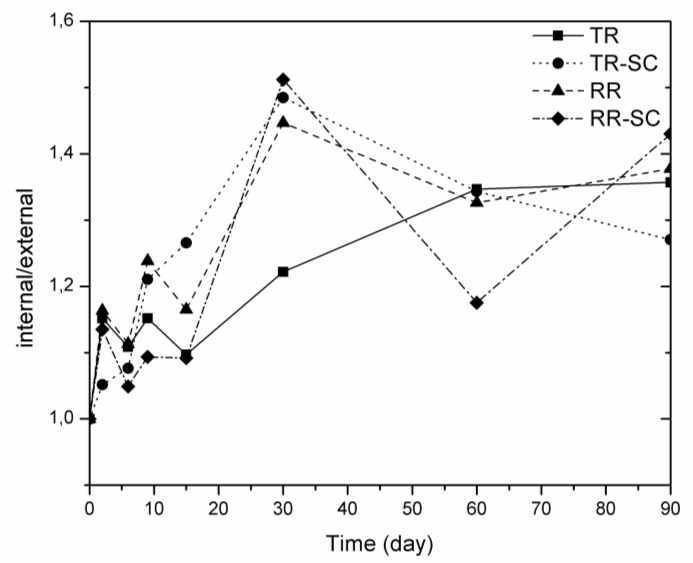

Figure 4. Evolution of moisture content ratio between internal and external fractions of non-inoculated and starter-inoculated (SC) Petrovská klobása sausages during drying/ripening in traditional room (TR) and controlled industrial ripening room (RR)

Figure 4. Evolution of moisture content ratio between internal and external fractions of non-inoculated and starter-inoculated (SC) Petrovská klobása sausages during drying/ripening in traditional room (TR) and controlled industrial ripening room (RR)This occurrence was particularly pronounced after 30 days of drying for RR-SC, TR-SC and RR sausages, when determined values of the observed indicator were 1.51, 1.48 and 1.45, respectively. Based on this fact, it can be concluded that fast and intensive pH drop stimulates the drying process, due to low water holding capacity of proteins, and has a strong influence on distribution of water inside the sausage. In next 30 days water content ratio in these groups decreased to 1.18, 1.34 and 1.33, respectively, indicating the equalization of moisture content in different fractions. During the last month of processing the monitored indicator in RR and RR-SC sausages increased again, as a consequence of thermo-hygrometric conditions (≈16°C and 65% RH) registered in industrial ripening room (Figure 1(b)). On the contrary, naturally fermented TR sausages showed the whole different water content ratio evolution, with the maximal value registered at the end of drying process.

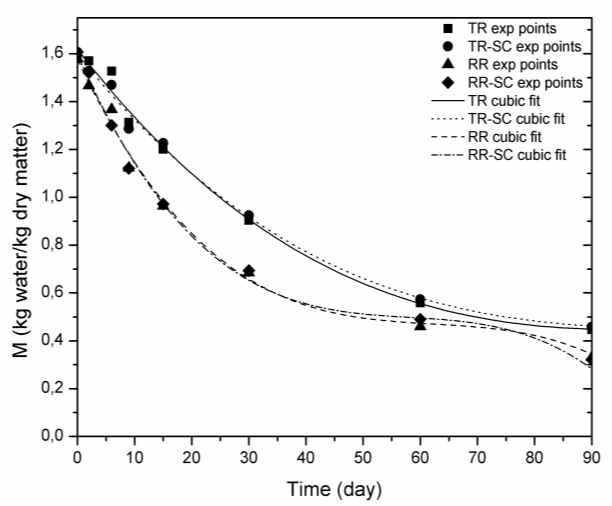

The experimental data obtained by determining the moisture content of sausages along the processing period were used to test the cubic decay function (Eq. 1) for describing the drying behavior of Petrovská klobása. Thus, table 2 summarizes the results of the batch drying data fitting for each sample sausage (TR, TR-SC, RR, RR-SC), obtained with the cubic polynomial function. The adequacy of the models has been evaluated by the coefficient of determination and its high values (r2>0.992) indicate good fit of experimental data. This is very important for defining the drying process and consequently the overall quality of Petrovská klobása.

Parameter |

TR |

TR-SC |

RR |

RR-SC |

|

a0 |

1.619 |

1.597 |

1.576 |

1.596 |

|

a1 |

-0.031 |

-0.030 |

-0.050 |

-0.054 |

|

a2 |

0.264x10-3 |

0.256x10-3 |

0.786x10-3 |

0.905x10-3 |

|

a3 |

-0.710x10-6 |

-0.740x10-6 |

-0.420x10-5 |

-0.520x10-5 |

|

r2 |

0.992 |

0.995 |

0.994 |

0.996 |

a0, a1, a2, a3 – regression coefficients

r2 - coefficient of determination

In Figure 5, the curves obtained with cubic decay fit are presented together with the experimental points, for non-inoculated and starter-inoculated sausages dried in different thermo-hygrometric conditions. It is possible to see that the greater water evaporation occurred for both types of sausages dried in RR.

CONCLUSIONS

From the present work, it can be concluded that drying of Petrovská klobása sausages in industrial ripening room, with different thermo-hygrometric conditions, resulted in different drying characteristics compared to those dried in traditional room. Higher diameter reduction (%) and lower aw and moisture content indicated 30 days shorter drying period in RR conditions. The addition of starter culture resulted in faster and more intensive pH drop, which had stimulated the drying process (water evaporation), and consequently influenced water distribution inside the sausage. The batch drying data for the sausages under study are well described by the cubic polynomial function (r2>0.992). Based on the obtained results, it can be concluded that the utilisation of SC and RR in processing of Petrovská klobása could be a potential technological improvement to shorten the drying period and to prolong the production season of this traditional meat product.ACKNOWLEDGEMENTS

This study was supported by the Ministry of Education, Science and Technological Development of the Republic of Serbia, Project No. TR31032.

JOURNAL TOOLS

JOURNAL TOOLS

INSTITUTE

INSTITUTE