Instrumental measuring of the hardness of fresh and cooked parsnip (Pastinaca sativa)

Bulevar cara Lazara 1, Serbia

2Faculty of Agriculture, Priština-Lešak, 38219 Lešak, Serbia

ABSTRACT

Introduction

The eating quality of vegetables can be measured directly by sensory methods or indirectly by different instrumental methods. Quality parameters should be measured easily for practical reasons and therefore simpler and faster instrumental methods are requested for the quality control of vegetables. Measurement of the basic mechanical properties also provides more reliable and repeatable tests then sensory evaluation (Bourne, 2002). In addition, measurement of food physical characteristics can give a better insight into the plant tissue structure and texture (De Belie et al., 2002), and can be used in the engineering process design (Bajkin et al., 2011). Textural changes during thermal processing of vegetables are often very intensive (Sila et al., 2005). Both cellular turgor and the integrity of cell walls are important components of the hardness of plant materials (Greve et al., 1994). These changes in cell walls are related to the changes in pectin structure caused by enzymatic degradation and non-enzymatic reaction of β-elimination which takes place at higher temperatures (Vu et al., 2004; Sila et al., 2005).Parsnip (Pastinaca sativa) is a root vegetable originating from Europe and Asia which belongs to the Apiaceae family together with carrot, celery, parsley and fennel (Koidis et al., 2012; Castro et al., 2013). It can be eaten fresh or cooked, usually in soups and stews (Rawson et al., 2010). Parsley, similar to carrot, contains C-17 polyacetylenes in minor quantities, which have been shown in recent studies to have anti-cancer, anti-inflammatory and anti-platelet properties (Rawson et al., 2010; Koidis et al., 2012).

Literature review indicates that carrot is the most examined root vegetable in terms of measuring different textural characteristics of both fresh and processed root. Tests performed on fresh or cooked carrots were usually based on compression, shearing or a combination of both (De Belie et al., 2002). Penetration/puncture test was used by different authors (Lin et al., 1998; De Belie et al., 2002; Rico et al., 2007, Bajkin et al., 2011) to measure the force required to penetrate the carrot disc by probe. Warner-Bratzler blade was also used to measure the force needed to cut through the carrot cylinder (Lin et al., 1998; Rastogi et al., 2008; Ayhan et al., 2008). The application of penetration test and cutting/shearing tests performed with different blade fixtures for measuring the textural characteristics of fresh carrots was examined in our previous research (Pestorić et al., 2013) and it was found that penetration test was the most suitable for the measuring of carrot hardness. However, there are only few research papers dealing with the texture of fresh or thermally treated parsnip. Bajkin et al. (2011) also used puncture test to measure the puncture force in the different measuring points (xylem and phloem tissue) on the fresh parsnip, parsley and celery root.

Considering all mentioned functional properties of parsnip root, as well as its shape which makes it suitable for the instrumental determination, the objective of this research was to apply different instrumental methods to measure the hardness of fresh and cooked parsnip. The change of parsnip firmness during cooking was also examined.

MATERIAL AND METHODS

Samples

Two commercial parsnip samples were purchased in market place from different producers, and the size of batch was approximately 3 kg (about 30 roots per batch). The samples were labelled as sample A and sample B, and washed with warm tap water. Afterwards parsnips were peeled with kitchen peeler to remove the root hairs, and stem end as well as lower part of the root (opposite to the stem end) were shredded using a meat slicer (Krups, Germany) before tests (Figure 1).Texture analysis

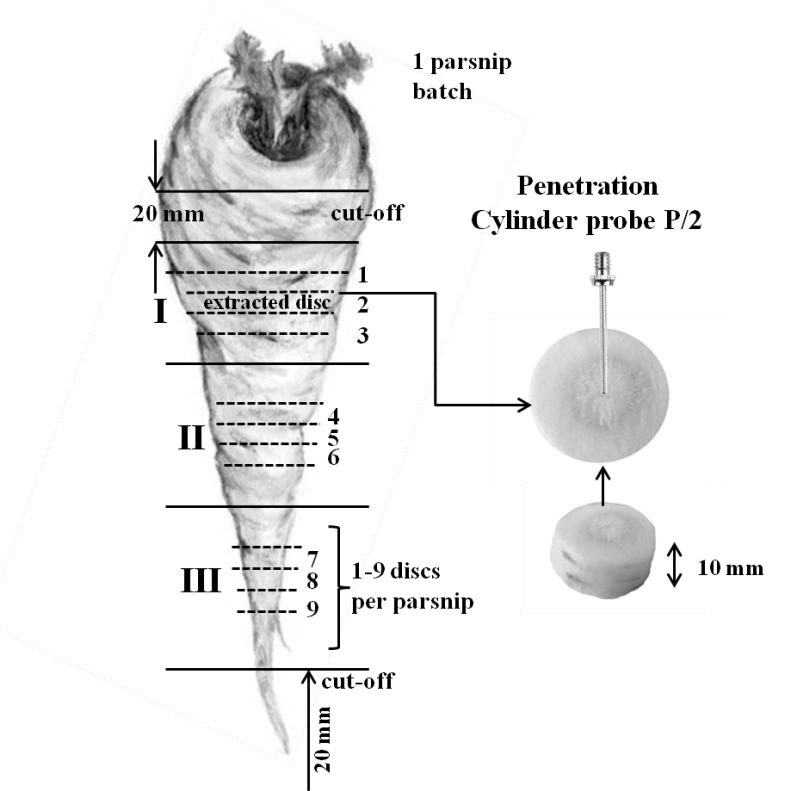

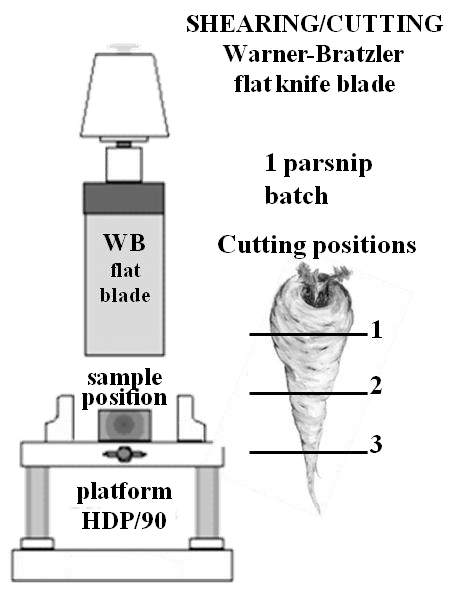

Texture analysis of parsnip was conducted using a TA.XTPlus Texture Analyser (Stable Micro Systems, England, UK). Penetration test and shearing test were performed in order to measure the hardness of fresh and cooked parsnip. Measurements were performed on three roots from each sample.For penetration test, nine discs with an approximate height of 10 mm were taken; three from the upper part of the parsnip root (I), three from the middle part (II), and three from the lower part (III) (Figure 1). Height of each parsnip disc was checked using measurement tool (Vernier caliper). The discs were cooked in the following way: 9 discs were put in a sufficiently large volume (about 1.5 L) of boiling water (100°C) for 5, 10, 15, and 20 min. After heat treatment they were immediately submerged in cold tap water for a few minutes, and afterwards put on the paper towel to soak up the water. Penetration test was performed with a 2 mm diameter stainless steel flat cylinder probe (P/2) and a 5 kg load cell. Instrumental settings were taken from the sample project (GRP1_P2) of the software package (Texture Exponent Software TEE32, version 6,0,6,0, Stable Micro Systems, England, UK), and according to published data (De Belie et al., 2002). Since according to Bajkin et al. (2011) xylem is the part of carrot and parsnip root with the highest puncture force values, hardness

in the centre of parsnip disc has been chosen as the most reliable indicator of changes during cooking. Shearing test was carried out using Warner-Bratzler (WB) flat knife blade fixture and a 30 kg load cell (Fig. 2). The same cooking procedure was used, with the two whole parsnip roots cooked in 2.0 L of boiling water. During this test, whole root was firstly cut at the middle, then at the middle of the upper part and finally at the middle of the lower part. Applied instrumental settings were taken from the sample project (SAU2_WBB) of the software package (Texture Exponent Software TEE32, version 6,0,6,0, Stable Micro Systems, England, UK), and path length of the WB knife was 40 mm.

Data analysis

Analysis of variance (ANOVA) and Fisher's least square difference (LSD) test were applied to compare means at 5% significance level using the statistical data analysis software system STATISTICA (2013). Results were expressed as the mean of replications ± SD for all measurements. Coefficient of variation (CV) was also calculated.Results and Discussion

Different instrumental methods for determining the hardness of fresh and cooked parsnip were applied, and the coefficient of variation was calculated because it represents a relative measure of error and therefore can be used for the comparison of variation from different methods or scales. Based on the results shown in Table 1. for penetration test and in Table 2. for shearing test, it can be concluded that CVs calculated for both methods are quite large, ranging from 10.82 to even 47.14. However, the lowest CV values (<25) obtained for the fresh parsnip samples imply that both methods are more suitable for the analysis of fresh rather than cooked samples.Sample |

Sample A |

Sample B |

||

|

Hardness (g) |

CV |

Hardness (g) |

CV |

|

|

Fresh |

2006±489b |

24.4 |

2625±284a |

10.8 |

|

Cooked for 5 min |

870±177a |

20.4 |

870±410a |

47.1 |

|

Cooked for 10 min |

1281±141a |

11.0 |

953±209b |

22.0 |

|

Cooked for 15 min |

358±155b |

43.5 |

626±236a |

37.7 |

|

Cooked for 20 min |

483±167a |

34.5 |

442±83a |

18.9 |

Results are expressed as a mean ± SD; CV - coefficient of variation; Values with the different superscript in the same row are statistically different (P<0.05)

Regarding the differentiation of parsnip samples, shearing test was not able to distinguish between neither fresh nor cooked samples A and B. Penetration test differentiated fresh samples, as well as samples cooked for 10 and 15 minutes. In our previous research, penetration test was also the most suitable for differentiation of fresh carrot samples (Pestorić et al., 2013). However, in that research, much lower CVs were obtained for fresh carrots. That could be due to the more heterogeneous texture of parsnip root comparing to the carrot root as measured by the puncture test (Bajkin et al., 2011).

Sample |

Sample A |

Sample B |

||

|

Hardness (N/mm) |

CV |

Hardness (N/mm) |

CV |

|

|

Fresh |

81.1±17.4a |

21.5 |

102.1±18.2a |

17.8 |

|

Cooked for 5 min |

28.5±7.0a |

24.6 |

33.2±9.7a |

29.3 |

|

Cooked for 10 min |

12.5±2.0a |

15.6 |

13.2±3.3a |

24.7 |

|

Cooked for 15 min |

9.4±4.3a |

45.7 |

10.8±2.4a |

22.4 |

|

Cooked for 20 min |

11.4±2.5a |

21.9 |

10.1±2.0a |

19.5 |

Results are expressed as a mean ± SD; CV - coefficient of variation; Values with the different superscript in the same row are statistically different (P<0.05)

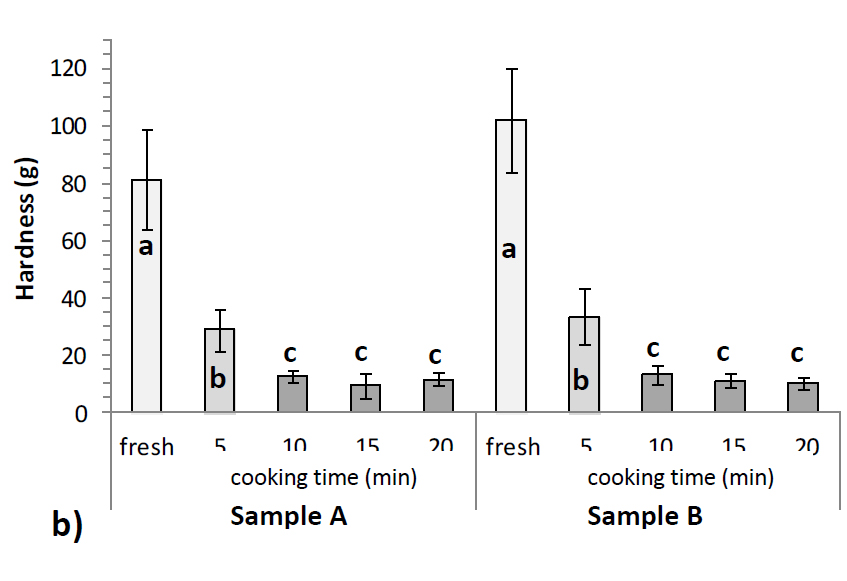

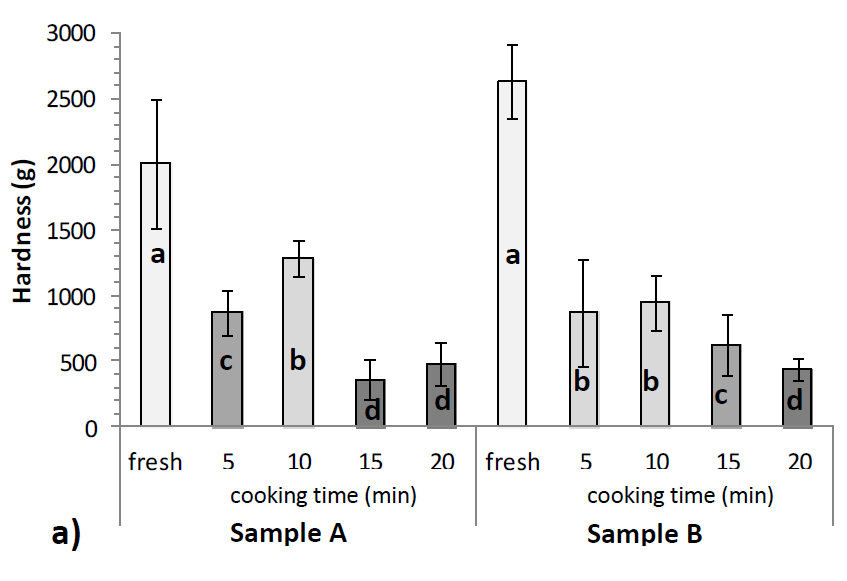

Hardness of fresh parsnip and its change during cooking is presented in Figure 3. The greatest change of hardness measured by both methods was observed after the first 5 minutes. These results are consistent with previous investigations of carrots, whose textural properties are changed most rapidly during the first few minutes of cooking (Greve et al., 1994; De Belie et al., 2002). Significant change of firmness was also observed between 5 and 10 minute of cooking as measured by shearing test, and after that there were no significant changes (Figure 3b). Trend of firmness decrease of sample A measured by penetration test had anomaly, i.e. parsnips cooked for 10 minutes were significantly firmer than those cooked for 5 minutes (Figure 3a). This could be explained by the great variability within the sample. However, parsnip samples A cooked for 15 and 20 minutes were significantly less firm than those mentioned above, indicating that longer thermal treatment nevertheless affected parsnip texture. Sample B expressed normal trend of firmness decrease, with significant differences observed between 10th and 15th minute of cooking, as well as between 15 and 20 minute. This marked difference between the samples’ trend of firmness decrease could be also explained by the fact that parsnip is firmer than carrot, and that 20 minutes of cooking is not enough time to observe the general trend of firmness decrease, regardless of the examined sample. Therefore, more different samples and a larger number of repetitions (tested roots) within the sample as well as longer cooking times are required to obtain the general conclusion. These results should also be confirmed by the sensory evaluation of firmness by a trained panel.

Figure 3. Hardness of fresh parsnip samples A and B and its change during cooking:

Figure 3. Hardness of fresh parsnip samples A and B and its change during cooking:a) penetration test, b) Warner-Bratzler flat blade shearing test;

Columns marked with different letters indicate significant difference.

Conclusions

Generally, penetration test was more suitable than shearing test for the measuring of fresh parsnip hardness, achieving both low CVs and sample differentiation. Further experiments on both fresh and cooked parsnips should be conducted on larger number of representative samples. Measurements should also be performed with more repetitions within the sample and with longer cooking times in order to draw general conclusion. In addition, results should be related to the hardness evaluated by an expert panel or a panel of trained assessors.АCKNOWLEDGEMENT

This paper is a result of the researches within the project III 46001, financed by the Ministry of Education, Science and Technological Development, Republic of Serbia.

JOURNAL TOOLS

JOURNAL TOOLS

INSTITUTE

INSTITUTE