ABSTRACT

Abstract

Fat and oils contribute to plasticity of dough, stabilize air cells, improve the gas retention and the quality of bread loaves and increase bread shelf life. Rice (Oryza sativa L.) is very nutritive, biologically active tropic plant and as non-gluten food is very interesting for production food with lower gluten content. By substituting wheat with rice flour, dough and bread have a low level of gluten and sodium and a high amount of easily digested carbohydrates which are desirable for certain special diets. In this paper were investigated rheological properties and lipid composition HPLC analysis of dough with wheat and various shares of white or brown rice flour with an emphasis on free fatty acids, methyl esters, monoacilglycerols, diacilglycerols and triacilglycerols content and their influence on dough rheology properties. Results show the white and brown rice flour addition has a positive influence on the quality number. Dough with higher oil content, had smaller values of water absorption and dough stability and higher values of degree of softening, when white or brown rice flour is used. HPLC results show only diacylglicerols had the same changing tendency – their content decrease when both, white and brown rice flour share rises. As properties of dough with both rice flour had the same dependency on their shares, diacilglycerols had specific influence on rice dough properties.

INTRODUCTION

Fat and oils in bread making industry are widely known as shortenings and they are used to improve the quality of bread loaves. Loaves with shortening differ significantly in volume and tenderness of texture from those without. Shorthening also delays the staling of bread, increasing its shelf life and prevent excessive development of gluten protein during mixture (Daniels et al., 1976). Increasing the level of fat in short dough has a softening effect on consistency of the dough (Miller, 1985). Fats and oil act as a lubricant and contribute to plasticity of dough. The addition of shortening is done principally to stabilize air cells that are generated by mixing (Maache-Rezzoug, 1998). During wheat flour mixing and dough development lipid-protein interaction occures. A acetic acids soluble-protein was indicated as component involved in work-induced lipid binding during dough development and in lipid relase on admission of air. Sub-fraction of acetic acids soluble-protein obtained by ammonium sulphate precipitation from aceticacids urea-cetyltrimethyl-ammo-nium bromide may have fundamental role in the formation of an insoluble glutenin structure through both -SH and hydrophobic interaction. This fraction is strongly complexed with tri-glycerid lipid on a 1:1 molar basis and showed a tendency to aggregate in solution (Fraizer et al., 2006). None of numerous hypothesis discussed in the literature provides an acceptable explanation for the mechanism by which fat improves loaf volume during baking although even in some of earliest publication it was accepted that fat somehow acts by allowing bubbles to expand during baking without rupturing. Solid fat has been hypothesised as providing a reservoir of crystals that melt in the dough as the temperature rises, thus providing a continous supply of melted fat to seal off leaks in expanding dough film and thus improve gas retention (Baldwin et al., 1963). Dough formulated with monogly-cerides preferentially bind to gluten and to outside part of the starch granules, resulting in strengthened gluten, delayed starch gelatinization, softer bread and delayed bread staling (Collar et al., 2004). Dough rheology and quality depend on dough mixing time and temperature (Brooker, 1996 and Dobraszczyk et al 2003), cyclodextrinase addition (Gujural et al., 2003), sage-extract addition (Davidović et al., 2005), fat (Cookson, et al., 2006) and fat–type (Jissy et al., 2007), etc.

HPLC is one of the most suituble techniques for lipid analysis because of its resolution, speed, sensitivity and reproducibility. By HPLC analysis of rice bran oil fatty acids, monoacilglycerols, diacilglycerols, triacilglycerols are separated. Content for MG was 2.34%, DG was 20.85%, TG was 2.46% and FA was 54.16%, with oleic, palmitic and myristic acid. Separation was obtained with a C18 column using aceton /acetonitrile/methanole(50:50:10 v/v/v) as a mobile phase at 30 oC with refractive index detection (Kadam et al., 2006).

Rice (Oryza sativa L.) is very nutritive, bio-logically active tropic plant and non-gluten food. As small part of the world population suffers from dietary wheat intolerance food with lower gluten content leastways for preventive purpose is needed, so rice as gluten free food is interesting (Moore et al., 2004). By substituting wheat with rice flour, dough and bread have a low level of gluten, sodium and fat and a high amount of easily digested carbohydrates which are desirable for certain special diets (Schober et al., 2003, Gallagher et al., 2003, Hema et al., 2004).

In this paper the rheological properties and lipid composition of dough with various shares of white and brown rice flour were investigated with an emphasis on free fatty acids (FA), methyl esters (ME), monoacilglycerols (MG), diacilglycerols (DG), triacilglycerols (TG) content and their influence on dough rheology properties.

MATERIALS AND METHODS

Flour

The wheat flour and rice were bought from the local market. The rice flour was obtained by milling short grains of white and brown rice. A 291, 285, 270, 255, 240, 225 and 210 g of wheat flour and 9, 15, 30, 45, 60, 75 and 90 g of rice flour, respectively, were used to make 300 g of dough mixture with 3, 5, 10, 15, 20, 25, and 30% (w/w) rice flour shares, without adding additives.

Oil content

The oil content was determined and isolated by n-hexane extraction in duplicate and by using reflux (1: 20 w/v at boiling temperature, 60 minutes). The extract dry content was determined on an analyzer (Scaltec SMO 01, Scaltec instruments, Germany). Extract was first poured, then dried at 110 oC to a constant weight and the dry residue content was read out on the analyzer display. For oil isolation, n-hexane extracts were combined and evaporated under vacuum.

Rheology measurement

The Brabender farinograph (Brabender Model 8 10 101, Duisburg, Germany) according to ISO 5530-1 test procedure, was used for water absorption values (WA value in ml), development time (DT in minutes), dough stability (DSt in minutes), degree of softening (DSf in FU) and farinograph quality number (QN) determination.

For extensograph measurement, the Brabender extensograph (Brabender, Model 8600-01, Duisburg, Germany) and test procedure ISO 5530-2 were used. The samples were prepared from flour, distilled water and salt, and data for extensibility (Ex in mm) and ratio number (R/Ex) were recorded on extensograph curve.

To obtain data for gelatinization temperature (Tmax in 0C) and gelatinization maximum (hmax in AU), the amylograph (Brabender Model PT 100, Duisburg, Germany and ISO 7973 test procedure were used.

HPLC analysis

For HPLC analysis, Holčapek et al. (18) modified HPLC method was used. The equipment was consisted of Agilent 1100 High Performance Liquid Chromatograph, equipped with a degasser, a binary pump, a Zorbax Eclipse XDB-C18 column (4.4 m x 150 mm x 5 mm) and an UV/Vis detector. The flow rate of binary solvent mixture (methanol, solvent A, and 2-propanol/n-heksane, 5:4 by volume, solvent B) was 1 ml/min with a linear gradient (from 100% A to 40% A+ 60% B in 15 min). The colume temperature was held constant at 40 oC. The components were detected at 205 nm. The mono-, di- and tri- acilglycerols were identified by comparison of retention times of the lipid components with those of standards. The samples of the reaction mixture were dissolved into a mixture of 2-propanol:n-heksane, 5:4 v/v and filtered through 0.45 mm Millipore filters.

RESULTS AND DISCUSSION

The results of oil content investigation in flour and dough with various rice flour shares are given in Table 1. The wheat flour was type 400, quality number (QN) B1 and had 1.9% oil content. The oil content in white and brown flour was 1.3 and 2.8%, respectively. The brown rice flour has higher oil content, because bran, as the part of a grain with highest oil content, is its constituent. So, all the dough with white rice flour had less and dough with brown rice flour had higher oil content than wheat flour.

Table 1.

|

Dough oil content (%)

|

Flour

|

3%

|

5%

|

10%

|

15%

|

20%

|

30%

|

|

White rice flour

|

1.3

|

1.88

|

1.87

|

1.84

|

1.81

|

1.78

|

1.72

|

|

Brown rice flour

|

2.8

|

1.93

|

1.95

|

1.99

|

2.03

|

2.08

|

2.17

|

The oil content in rice flour and dough made of wheat and different shares of rice flour

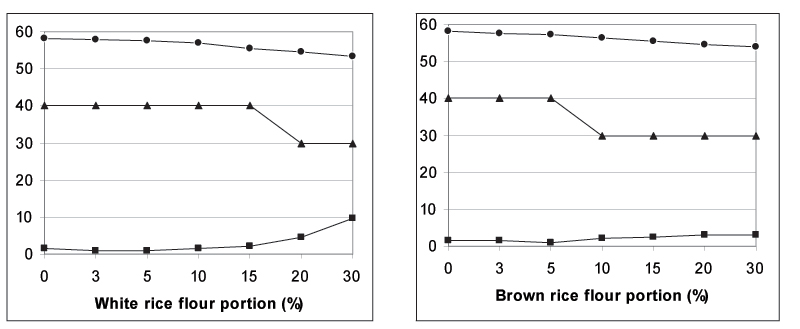

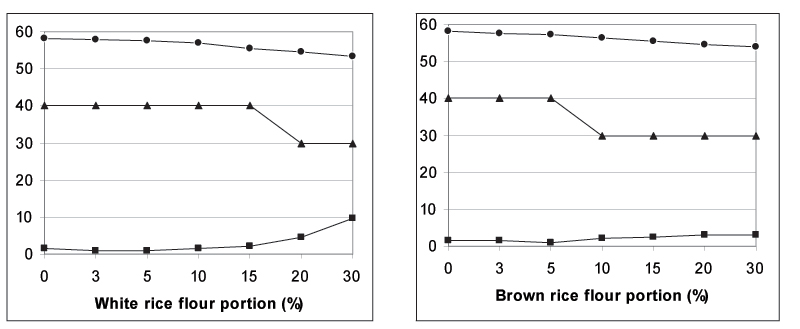

Some properties of dough made of wheat and rice flour mixture, are presented in Figure 1 and Table 2. The water absorption decreases with rising white rice flour shares from 58.0 to 53.5.0%, and also with rising the brown rice flour shares from 57.2 to 54.0%. This is due to the decrease of the gluten content in dough when white or brown rice flour are added, since rice is gluten free and the gluten is the main component in dough mixture responsible for water absorption and dough viscoelastic properties. The water absorption (WA) is less when rice flour is in dough, irrespective whether white or brown, in comparison to dough made from wheat flour only, where value was 58.2 cm3.

Dough with rice flour had better dough stability (DSt), especially in dough with white rice where it is 9.5 minutes compared to dough with wheat flour only where the value is 1.5 minutes. On the other side, the dough with 20 and 30% of white and 10, 15, 20 and 30% of brown rice flour had less degree of softening (DSf) than dough made from wheat flour only and dough with other shares of rice flour. All the values are still less than 75 FU, so the wheat and rice flour mixture can be considered as a good quality flour.

The white and brown rice flour addition has positive influence on the quality number and group of flour when the white rice flour share is higher than 15% and the brown rice flour share is higher than 10%. The group of flour is then A2, while it changes to top A1 when white rice flour share is 30%. The dough with white rice flour is in range 148 do 120 EU and with brown rice flour from 140 to 99 EU and all of these values are less than extensibility with wheat flour only. The ratio numbers, R/Ex, are various and in range of 1.90 to 2.33 for dough mixture with white rice flour, and in range of 2.40 to 3.43, for dough mixture with brown rice flour, so the volume of bread with brown rice flour will be less than bread with white rice flour. Both dough have higher gelatinization temperature and almost twice the higher viscosity of cooled paste compared to dough from wheat flour only. These results show, dough with higher oil content, have smaller values of WA and Ds and higher values of Dsf, in both cases, when white or brown rice flour is used.

Figure 1. Effect of rice flour shares on some dough properties (· - water absorption in ml; - dough stability in minutes; ¢ - dough softening in FU)

Table 2.

|

|

Wheat flour

|

3%

|

5%

|

10%

|

15%

|

20%

|

30%

|

|

Dough mixture with white rice flour

|

|

QN

|

68

|

62.9

|

65.2

|

66.4

|

70.7

|

79.2

|

87.5

|

|

Group

|

B1

|

B1

|

B1

|

B1

|

A2

|

A2

|

A1

|

|

R (EU)

|

370

|

320

|

310

|

310

|

270

|

280

|

280

|

|

Ex (mm)

|

144

|

148

|

148

|

145

|

142

|

136

|

120

|

|

R/Ex

|

2.57

|

2.16

|

2.09

|

2.14

|

1.90

|

2.06

|

2.33

|

|

T max (0C)

|

88.4

|

88.0

|

87.2

|

87.2

|

88.7

|

98.1

|

98.1

|

|

hmax (AU)

|

480

|

490

|

500

|

560

|

595

|

635

|

790

|

|

Dough mixture with brown rice flour

|

|

QN

|

68

|

65.0

|

65.9

|

72.8

|

76.9

|

82.7

|

78.4

|

|

Group

|

B1

|

B1

|

B1

|

A2

|

A2

|

A2

|

A2

|

|

R (EU)

|

370

|

380

|

370

|

350

|

350

|

350

|

340

|

|

Ex (mm)

|

144

|

140

|

154

|

136

|

131

|

118

|

99

|

|

R/Ex

|

2.57

|

2.71

|

2.40

|

2.57

|

2.67

|

2.96

|

3.43

|

|

T max (0C)

|

88.4

|

86.5

|

86.8

|

88.0

|

88.9

|

90.2

|

90.2

|

|

hmax (AU)

|

480

|

520

|

560

|

610

|

680

|

715

|

870

|

Properties of dough with different shares of white and brown rice flour

In table 3 the HPLC analysis results of flour oil are presented. The content of components is determined by measuring the peak area at 1.76 min for free fatty acids, peak area at 2.152 min for methyl esters, peaks area in a range of 3.445-4.580 min for monoacilglycerols, peaks area in a range of 5.276-8.677 min for diacilglycerols and peaks area in a range of 10.907-15.815 min for triacilglycerols. The highest free fatty acids content had white rice flour. The methyl esters content are diverse and wheat flour had highest content of 23.77%, while the highest content of mono-, di- and tri acilglycerols, had white rice flour, wheat flour and brown rice flour, respectively. In table 4 the content of these lipid components in dough with different rice flour shares are given.

Table 3. HPLC oil analysis of wheat and rice flour

|

|

Fatty

acid

|

Methyl

esters

|

Mono-

acilgycerols

|

Di-

acilgycerols

|

Tri-

acilgycerols

|

|

Wheat flour

|

12.00

|

23.77

|

2.17

|

13.51

|

48.55

|

|

White rice flour

|

36.32

|

4.18

|

5.39

|

8.99

|

45.12

|

|

Brown rice four

|

7.27

|

1.68

|

0.81

|

7.25

|

83.00

|

In dough with white rice flour the free fatty acids and monoacilglycerols content rises, and these contents in all dough are higher than in dough made of wheat flour only. The content of other components decreases when the white rice flour share rises.

In comparison to dough with wheat flour only, the content of methylesters is higher when share of white rice flour is 5-30%, while content of diacyglycerols is higher only in dough with 3% of white rice flour.

Table 4. HPLC analysis of components in doughs with different shares of rice flour

|

|

Free fatty

acids

|

Methyl

esters

|

Mono-

acilglycerols

|

Di-

acilglycerols

|

Tri-

acilglycerols

|

|

Dough mixture with white rice flour

|

|

3%

|

12.63

|

23.18

|

2.28

|

15.32

|

48.44

|

|

5%

|

13.22

|

22.79

|

2.33

|

13.28

|

48.38

|

|

10%

|

14.43

|

21.81

|

2.47

|

13.05

|

48.20

|

|

15%

|

15.65

|

20.83

|

2.66

|

12.83

|

48.04

|

|

20%

|

16.86

|

19.86

|

2.82

|

12.59

|

47.86

|

|

30%

|

19.30

|

17.89

|

3.14

|

12.15

|

47.53

|

|

Dough mixture with brown rice flour

|

|

3%

|

11.85

|

23.18

|

2.23

|

15.27

|

49.58

|

|

5%

|

11.76

|

22.79

|

2.10

|

13.19

|

50.27

|

|

10%

|

11.53

|

21.71

|

2.01

|

12.88

|

51.99

|

|

15%

|

11.29

|

20.83

|

1.97

|

12.56

|

53.72

|

|

20%

|

11.05

|

19.86

|

1.9

|

12.35

|

55.44

|

|

30%

|

10.60

|

17.90

|

1.76

|

11.62

|

58.85

|

In dough with brown rice flour the content of free fatty acids, methylesters, mono- and di-acilglycerols decreases, while the content of triacilglycerol rises when the share of brown rice flour rises. The content of free fatty acids and methylesters are less than appropriate content in dough with wheat flour only. The content of mono and di-acilglycerols is higher only in dough where brown rice flour share is 3%, while the content of tri-acilglycerols is higher in dough with all shares of brown rice flour in comparison to those contents in dough whith wheat flour only (Hema et al., 2004).

HPLC analysis results show that only DG had the same changing tendency – their content decrease when both, white and brown rice flour share rises. As properties of dough with both rice flour have the same dependency on their shares, (R and Ex rises and Tmax and hmax decreases), it seems that DG has specific influence on dough properties. Only difference is in R/Ex ratio tendency: it decreases when white rice flour share rises and rises when brown rice flour share rises. This ratio effects loaf volume and it is best when ratio value is 1.8, so values over or below this one shows, whenever white or brown rice flour is used, that loaf volume is lower then in cases when wheat flour only is used.

CONCLUSIONS

The white and brown rice flour addition has a positive influence on the quality number. Dough with higher oil content, had smaller values of water absorption and dough stability and higher values of degree of softening, when white or brown rice flour is used. HPLC results show only diacylglicerols had the same changing tendency – their content decrease when both, white and brown rice flour share rises. As properties of dough with both rice flour had the same dependency on their shares, dia-cilglycerols had specific influence on rice dough properties.

ACKNOWLEDGMENTS

This work was supported under the project TR-6708 B by the Ministry of Science and Enviroment Protection of the Republic of Serbia.

Download full article PDF

DOWNLOAD PDF

DOWNLOAD PDF

Figure 1. Effect of rice flour shares on some dough properties (· - water absorption in ml; - dough stability in minutes; ¢ - dough softening in FU)

Figure 1. Effect of rice flour shares on some dough properties (· - water absorption in ml; - dough stability in minutes; ¢ - dough softening in FU)

JOURNAL TOOLS

JOURNAL TOOLS

INSTITUTE

INSTITUTE