Influence of thermal treatments on starch gelatinization and in vitro organic matter digestibility of corn

ABSTRACT

Corn contains 72% of DM as starch. In ruminant nutrition corn grain is typically processed prior to feeding because a whole grain has an intact pericarp that prevents bacterial attachment and subsequent digestion of the seed constituents. Most common processing techniques use various combinations of heat, moisture, time, and mechanical action that may affect starch availability by altering starch properties. In the present study influence of pelleting, steam flaking, micronization and extrusion processing methods on water absorption index (WAI), water solubility index (WSI), degree of gelatinization and organic matter digestibility (OMD) of corn in ruminants was examined. All hydrothermal treatments used in this study caused gelatinization of normal semi-crystalline structure of starch granules but in various extents. Low extent of gelatinization was achieved using steam flaking (21,33%) and pelleting (25,47%). Higher extent of gelatinization was achieved using micronization (63.58%) and extrusion (100%). Statistically significant increase in OMD value compared to unprocessed corn was obtained only after extrusion processing indicating that that all nutrients became more available after extrusion.Introduction

Corn is the most common raw material used in animal diets. In diets for young animals corn accounts for 55-60% and 60-70% in diets for fattening animals (Grbeša, 2008). In ruminant nutrition cereals are the most valuable energy source, and in Serbia the most widespread cereal grain is corn (Grubić and Adamović, 2003).Corn contains 72% of DM as starch (Huntington, 1997). Starch is accumulated in granules in the endosperm and it is deposited in layers with various amylose and amylopectin content. The starch granule consists of alternating semi-crystalline and amorphous layers. Most starches will gelatinize upon heating to above 80°C in excess water. Svihus et al. (2005) describes gelatinization as a swelling driven process. Swelling occurs along the amorphous regions, and since the crystalline regions do not expand during swelling, stress increases at the interface between the crystalline and amorphous regions, where bonds exist between amylopectin in the crystalline regions and amylose in the amorphous regions. Thus, at a certain point in the swelling process the crystalline regions are rapidly and irreversibly broken and gelatinization is initiated. Swelling causes nearly all amylose in the starch granule to leach out (Nur and Purwiyatno, 2010). Viscosity increases during gelatinization and is caused by swollen granules and gels consisting of solubilized amylose (Svihus et al., 2005).

A variety of methods for the monitoring of gelatinization of starch are available, such as different microscopic, thermoanalytical, enzymatic and rheological methods (Pojić et al., 2013). Rheological methods are based on the measurement of viscosity changes during heating and shearing of starch slurries. For this purpose, different instruments are available including Brabender Visco Amylograph (BVA) and Micro Visco Amylograph (MVA), Rapid Visco Analyzer (RVA), Ottawa starch viscometer and viscometer.

Modification of dietary feed components by processing is one way to enhance its nutritional value and improve animal performance. The feeding value of any feed is a function of three factors: nutrient content, intake, and digestibility. In ruminant nutrition corn grain is typically processed prior to feeding because a whole grain has an intact pericarp that prevents bacterial attachment and subsequent digestion of the seed constituents (Huntington, 1997). Most common processing techniques use various combinations of heat, moisture, time and mechanical action that may affect starch availability by altering starch properties.

Pelleting is a process of forcing and shaping bulk material trough die with specific dimensions of openings and thickness. Aim of pelleting is to obtain feed pellets with optimized physical and improved nutritional quality. Prior to pelleting feed is steam conditioned so it is converted in physical state which is more suitable for compaction. Conditioning increases production capacity and, at the same time, affects physical, nutritional and hygienic quality of produced feed (Čolović et al., 2010).

Extrusion cooking is a high-temperature short-time process in which a final product is obtained by heating, mixing, shearing and forcing material through a die. High temperature (up to 200°C) is a direct result of friction (dry extrusion), or pre-conditioning and steam injection (wet extrusion), or a combination of both. Material is also exposed to relatively high pressure, which can range up to 25 MPa.

The micronization is a process where the infra-red rays excite the molecules in the seeds which vibrate at a frequency of 80-170 mega cycles/s resulting in rapid internal heating and a rise in water vapor pressure (Sharma, 2009). Rise in water vapor pressure in seeds causes material to become soft and plastic, resulting in swelling and fracture of the materials. During this process, starch molecules burst out and get gelatinized. The soft, ruptured grain is then rolled and flaked when the starch is gelatinized thus considerably enhancing the grain's digestibility and feeding value (Boychuk, 1997).

Steam flaking is considered the process of steaming whole grain at atmospheric pressure, typically for 20 to 40 minutes and then rolling it to a flake. Good conditioning is essential to deliver a softer grain to the mills, increasing flake quality by reducing fines.

Through interaction of heat, moisture and pressure at different thermal treatments of cereal grains, the destruction of endosperm structure and protein matrix that surrounds starch granules in grain endosperm, and gelatinization of normal semi-crystalline structure of starch granules is achieved (Stojanović et al., 2005). In this way greater availability of starch to ruminal microflora enzymes is ensured and starch utilization in the rumen of ruminant.

The purpose of this study was to evaluate the effects of pelleting, extrusion, micronizing and steam flaking on water absorption and solubility index (WAI and WSI), degree of starch gelatinization and in vitro organic matter digestibility (OMD) of corn grain.

MATERIAL AND METHODS

In this research ZP 666 variety of corn grown in Serbia in year 2012 was used. Before all treatments, whole or milled corn grain was steam conditioned. Moisture content of conditioned corn was 14,36%, 16,51%, 14,29% and 17,31% before steam flaking, pelleting, micronization and extrusion, respectively. Pelleting and extrusion of corn was performed at pilot-plant facility of Institute of Food Technology (Novi Sad, Serbia). Corn was ground using a hammer mill (Model 11, ABC Engineering, Pančevo, Serbia) fitted with a 4 mm sieve. The material was pelleted on a flat die pellet press (model 14-175, Amandus Kahl, Germany). The diameter of pellet die openings was 6 mm, with die thickness of 36 mm. The material was extruded using single screw extruder (model OEE 8, AMANDUS KAHL GmbH & Co. KG, Germany), through die with 8 mm diameter openings. Micronization of whole corn grain was carried out at feed factory “Komponenta” in Ćuprija, Serbia. Steam flaking of whole corn grain was performed at feed factory “Opulent” in Čurug, Serbia.The water absorption index (WAI) and water solubility index (WSI) were determined according to the method described by Lazou and Krokida (2010): distilled water (5 mL) was added to ground sample (0.2 g) in a weighed 15 mL glass centrifuge tube. The tube was agitated on a Vortex mixer for 2 min and then centrifuged for 20 min at 700 g. The supernatant liquid was poured into a tarred evaporating dish. The remaining gel was weighed and the WAI was calculated as:

WAI=mg/ms

where mg is the weight of the hydrated gel (g) and ms is the weight of sample (g).The water solubility index (WSI) was determined from the amount of dry solids recovered by evaporating the supernatant from the water absorption test as:

WSI=mds/msx100

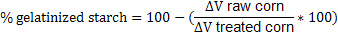

where mds is the weight of dry solids from the supernatant (g) and ms is the weight of the sample (g).Viscosity was measured on Haake Mars rheometer (Thermo Scientific, Germany) equipped with Z43S measuring cup and FL2B propeller shaped rotor with 2 blades. Viscosity profiles of samples were recorded using 15% DM corn suspensions. A programmed heating and cooling cycle was used, where the samples were held at 25°C for 3 min, heated to 95°C at 1,5°C/min, held at 95°C for 15 min, before cooling from 95 to 25°C at 1,5°C/min and holding at 25°C for 3 min. The degree of gelatinization is defined as:

ΔV= (VF- Vi)

where VF is the suspension viscosity at gelatinization peak, and Vi is the initial viscosity of suspension (Figure 1). A decrease in ΔV indicates an increase in the degree of gelatinization (Lai and Kokini, 1991).

Figure 1. Viscosity profiles of corn suspension (unprocessed and extruded corn)The percentage of gelatinized starch has been calculated based on assumption of zero gelatinized starch in the raw corn as follows:

Organic matter digestibility of corn in ruminants was determined according to method described by Pojić et al. (2008) and modified by Kokić et al. (2013). The dried and ground sample was first treated with pepsin hydrochloric acid to dissolve the protein fraction. The mixture was then heated to 80 °C to hydrolyse the starch and inactivate the pepsin. After washing with water, the mixture was incubated with a mixture of enzymes that are capable of dissolving digestible carbohydrates from cell walls and starch. The undissolved residue was then washed with boiling water and acetone to extract the fat. Consequently, content of dry matter and ash was determined for the undissolved residue.

All analysis were performed in triplicate. One-way ANOVA and Tukey HSD test were used to analyze variations of the results. Differences between the means with probability p < 0.05 were accepted as statistically significant and differences between the means with 0.05 < p < 0.10 were accepted as tendencies towards differences. The level of confidence was set at 95% (STATISTICA 10.0, StatSoft Inc., Tulsa, OK, USA).

Results and Discussion

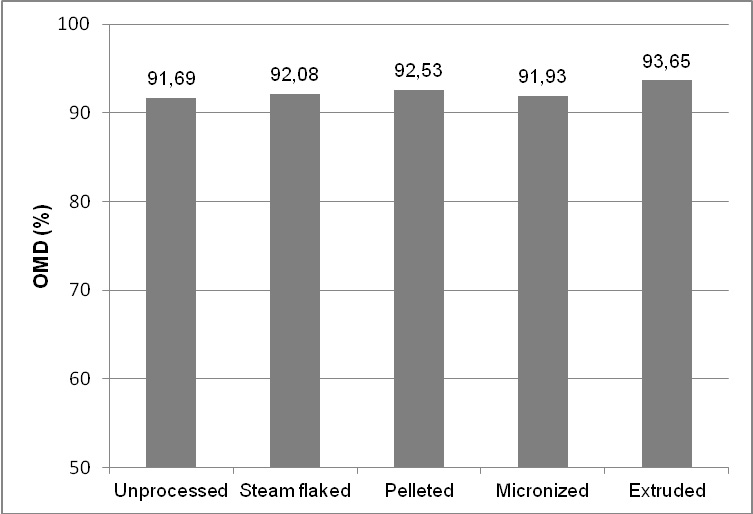

The effect of hydrothermal treatments on the in vitro OMD values in feed for ruminants is presented in Figure 2.

In vitro OMD varied from 91,69% (unprocessed corn) to 93.65% (extruded corn). Statistically significant increase in OMD value compared to unprocessed corn was obtained only after extrusion processing (p < 0.05). All other used treatments did not show significant effect regarding OMD. Similar results were also obtained by Bailoni et al. (2006). In this experiment the in vitro OMD of corn was unaffected by flaking and extrusion.

The WAI measures the amount of water absorbed by starch and can be used as an index of gelatinization, since native starch does not absorb water at room temperature (Lazou and Krokida, 2010). The WSI is related to the quantity of soluble molecules, which is related to dextrinization. In other words, WSI can be used as an indicator for the degradation of molecular compounds and measures the degree of starch conversion (Ding et al., 2006). The effect of hydrothermal treatments on WAI, WSI and degree of gelatinization are presented in Table 1.

Treatment (processing temperatures) |

WAI (g/g) |

WSI (g/100g) |

Gelatinization (%) |

|

Unprocessed |

2.47±0.09 a |

5.52±0.17 b |

0 a |

|

Steam flaked (85°C) |

3.20±0.08 b |

3.04±0.38 a |

21.33±0.42 b |

|

Pelleted (61°C) |

2.99±0.07 b |

5.45±0.27 b |

25.47±0.80 c |

|

Micronized (125°C) |

3.59±0.05 bc |

5.34±0.32 b |

63.58±0.35 d |

|

Extruded (95°C) |

5.93±0.18 d |

18.79±0.82 c |

100.00 e |

Results are given as mean ± standard deviation (n = 3)

Column values followed by the same superscript are not significantly different (p≤0.05)

All hydrothermal treatments used in this study caused gelatinization of normal semi-crystalline structure of starch granules but in various extents. Low extent of gelatinization was achieved using steam flaking (21,33%) and pelleting (25,47%). According to Svihus et al. (2005), during steam conditioning and pelleting only between 1 and 20% of starch is usually gelatinized. Also, WAI and WSI values were unaffected or slightly higher after these thermal treatments. Obtained results imply that mild processing methods such as steam flaking and pelleting do not have marked effect on starch availability and OMD. On the other hand, extrusion caused all starch to gelatinize despite the lower temperature compared to micronization (100% vs 63,58%). Possible explanation for this could be higher moisture content prior to extrusion. High gelatinization rate during extrusion was confirmed with WAI and WSI values that were significantly higher in comparison to unprocessed corn (5,93 vs 2,47 g/g, 18,79 vs 5,52 g/100g, respectively). Extrusion usually results in a more complete gelatinization and disintegration of starch granules (Skoch et al., 1983, Svihus et al., 2005). Hence, OMD increases which indicates that all nutrients (including starch) became more available after extrusion.

Conclusions

All hydrothermal treatments used in this study caused gelatinization of normal semi-crystalline structure of corn starch granules but in various extents. Moisture content of conditioned material before processing and achieved temperature during processing are dependent on selected processing method. These two factors have a great impact on disintegration of starch granule. Based on obtained results, pelleting and steam flaking are mild processing methods whereas micronization and extrusion are more severe methods that cause more starch to gelatinize and to increase its availability. In the present study increase in OMD value in comparison to unprocessed corn was achieved only after extrusion.

АCKNOWLEDGEMENTS

This paper is a result of the research within the bilateral cooperation between Republic of Serbia and Slovak Republic, “Laboratory methods for the assessment of feeds” (2012-2013) and project III46012 financed by the Ministry of Education, Science and Technological Development, Republic of Serbia.

JOURNAL TOOLS

JOURNAL TOOLS

INSTITUTE

INSTITUTE