Influence of different packaging solutions on qualitative and quantitative properties of fresh tomato variety Izmir during storage at market conditions

ABSTRACT

Introduction

According to available data more than 30% of harvested fresh fruit and vegetables are lost due to inadequate postharvest treatment with the losses being even higher in less developed countries (Aulakh and Regmi 2013). From the postharvest point of view processes that are involved in deterioration are starting immediately and are more extensive due to specific respiration processes in fruits (Irtwange 2006, Kantola. and HelÉN 2001, Pinheiro et al. 2013, Ali et al. 2010, Majidi et al. 2012). In order to decrease losses and preserve quality of fresh fruit and vegetables appropriate postharvest handling solutions are optimized and applied: storage under optimal temperature (Irtwange 2006, Ali et al. 2010) and relative humidity conditions (Kantola. and HelÉN 2001), treatments with approved chemical and physical treatments or modification of composition of the storage atmosphere (Fonseca et al. 2002, Ščetar et al. 2010). However, factors influencing postharvest shelf life of fresh produce like moisture loss, development of pathogens, respiration rates etc. can be further decreased by packaging of the fruits in packaging units providing optimal equilibrium atmosphere and protection to stored fruits (Workneh et al. 2012).

Tomato is climacteric fruit and fully ripened red fruits have relatively short post-harvest life of up to 2 weeks, since many processes affecting quality loss take place after harvest. Control of postharvest processes in tomato fruit through the use of optimal combination of temperature and humidity as the most commonly used and the cheapest approach, is limited with the fact that low storage temperatures which are reliable for retention of freshness and extension of shelf-life by reduction of respiration rate and thermal decomposition, result in chilling injuries of tomato fruits if the temperature lower than 12.5 - 8.5 °C (this temperature depends on variety, stage of maturity, duration of storage, growing conditions…) is applied making thus the issue of prolonging of shelf life of fresh tomato even more delicate.

Development and selection of appropriate packaging system through selection of adequate packaging materials and the manner in which tomato is packed represent other possibility for prolongation of tomato shelf-life in controlled storage conditions (Irtwange 2006). Packaging materials being reported as suitable for packaging of fresh tomato include conventional packaging materials such as polyvinyl chloride (PVC), polyethylene terephtalate (PET), polypropylene (PP) and polyethylene (PE) (Mangaraj et al. 2009). Materials produced from renewable sources like cellophane, reported to be suitable for packaging of fresh fruits and vegetables can also be considered as possible solutions for improvement of tomato properties during its shelf life. Regarding packaging solutions perforated films and sealed packages (Kantola. and HelÉN 2001, Mangaraj et al. 2009) providing differences regarding water permeability, atmosphere composition inside package and protection from external influences and contamination can be applied to expand shelf life of fresh produce including fresh tomato. Modified atmosphere packaging (MAP) is technique widely used for vegetable products (Kantola. and HelÉN 2001). Application of MAP as the technique enabling further improvement of postharvest shelf life properties of fresh produce including fresh and fresh cut tomato is commercially limited with requirements for special equipment and additional production costs (Irtwange 2006, Kantola. and HelÉN 2001, Pinheiro et al. 2013, Fonseca et al. 2002, Mangaraj et al. 2009). As applicable solution, reconciling optimal storage costs and beneficial effects of convenient storage atmosphere the possibility of development and preservation of the most convenient equilibrium state atmosphere obtained by selection of appropriate packaging material, and storage conditions influencing the fruit respiration rate is being extensively investigated (Irtwange 2006, Kantola. and HelÉN 2001, Pinheiro et al. 2013, Ali et al. 2010, Majidi et al. 2012, Fonseca et al. 2002, Workneh et al. 2012).

The goal of this research was to compare changes of quantitative (weight loss) and qualitative (color, texture) properties of fresh tomato variety Izmir during the storage under controlled temperature conditions in different conventional polymer packaging materials (PE, cellophane) with perforated and sealed packaging solutions at the temperature conditions characterizing common situation at the fresh produce market.

MATERIAL AND METHODS

Plant material

Fully ripe tomato fruits (Solanum lycopersicum “Izmir”) were collected from glasshouse from early winter production in November. The temperature in the glasshouse during the production was maintained above 13 °C with daily oscillation in the range from 15 to 20°C. The production was conducted according to good agriculture practice for late tomato production, including irrigation, controlled fertilization, bumblebee pollination, etc.

Tomato packaging and packaging materials

Tomato fruits were divided to five equal subsamples. Every individual fruit was marked and four of them were packed in selected packaging materials: polyethylene (PE) film, perforated PE film, cellophane, perforated cellophane. Perforated packaging has 20-25 perforations of 5 mm diameter, per replication. Packaging materials were purchased locally and their thickness was 40 and 10 μm for PE and cellophane respectively. Non packed tomatoes were used as control. For each packaging material four replicates were formed and stored under controlled storage conditions (temperature 20 °C (± 1 °C) and 95 % RH (± 5%)) during 8, 15 and 22 days.

Quality parameters

Weight loss during storage was calculated as the difference between initial and final fruit weight for observed storage interval and expressed as weight loss per day during the storage intervals.

Surface color was measured with Konica Minolta Chromameter CR-400. The* (red-green) and b* (yellow-blue) were read using a D65 light source and the observer angle of 2°. Tomato fruit surface color values were measured at two predetermined points at the middle of each fruit and average value was calculated. The changes in color for tomato fruit was reported with value a* and b*. Color difference between two samples (ΔEab*) was calculated according to Young and Whittle (1985).

Texture measurements were performed by TPA (Texture Profile Analysis) tests of tomato samples using a TA.XT Plus Texture Analyser (Stable Micro Systems, England, UK), equipped with 30 kg load cells. In the measurements of texture profile (TPA.PRJ), the fruit samples were compressed twice with a 100 mm diameter stainless steel cylinder (P/100). Both instrumental settings (GRP1_P2; TPA.PRJ) were taken from the sample projects of the software package (Texture Exponent Software TEE32, version 6.0, Stable Micro Systems, England, UK).

Weight loss and texture parameters were measured in four replications while a* and b* were measured in eight replications per packaging material per sampling day. Obtained means were compared by ANOVA while differences among individual means were calculated using DUNCAN’S multiple range test.

Results and Discussion

Analysis of influence of tested packaging solutions on properties of fresh tomato during its shelf life included comparison of tested packaging materials (PE and cellophane) and comparison of packaging solutions (with perforation and sealed) regarding quantitative and qualitative properties of packed tomato. All tested packaging solutions were compared to non-packed fruits stored under the same temperature and relative humidity conditions.Quantitative properties

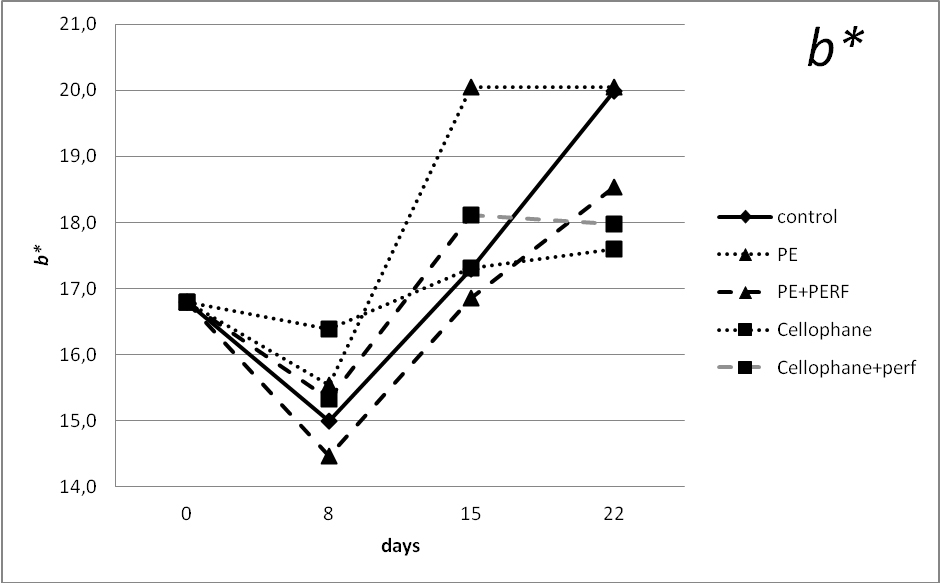

Quantitative properties of tomato fruits were characterized with the gradient of weight loss of stored fruits during the shelf life period presented in Figure 1.

The largest difference in weight loss gradient was determined between samples packed in sealed packaging materials (PE and cellophane) at one side and non-packed samples and samples packed in perforated films (PE and cellophane) at the other side. Sealed samples showed only slight decrease in weight of less than 0.1 g/day with the same trend during the whole storage interval. As expected non-packed samples were characterized with the highest weight loss due to undisturbed evaporation process of tomato samples stored at 20°C in spite of high relative humidity (95%) which was maintained during the whole storage period. Another important observation is that the weight loss gradient is higher during the first week of tomato storage ranging up to 0.8 g/day, during the second week it is almost halved indicating that equilibrium surrounding conditions and tomato evaporation is reached. The weight loss gradient increases slightly again after relatively long storage period of over two weeks, pointing out at possible initiation of degradation processes in non-packed fruits resulting in additional free water generated by biochemical processes involved.

Regarding weight loss tomato fruits packed in perforated PE film expressed similar behavior like non-packed tomato but at approximately 0.1 g/day lower level. Oppositely, weight loss gradient of tomato fruits packed in perforated cellophane was stable during the whole storage period and significantly lower in the first storage week in comparison to non-packed samples and samples packed in perforated PE.

Qualitative properties

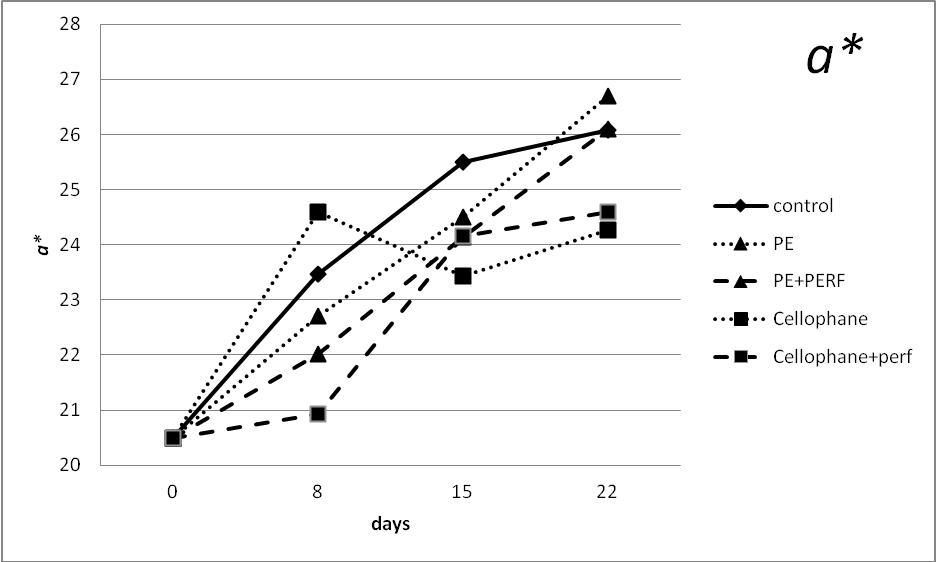

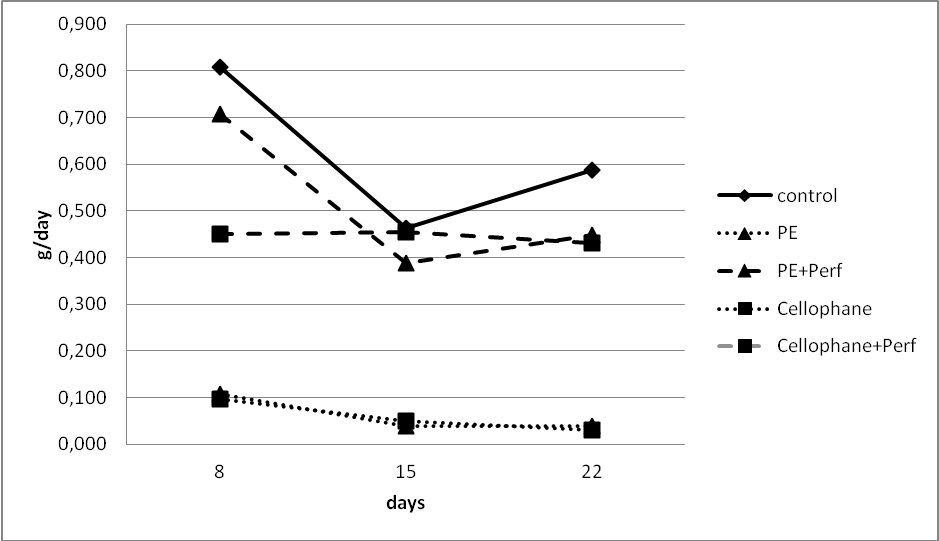

Qualitative characterization included color and texture properties changes. The most important parameter that describes color of fully ripened fruits and vegetables is value a* which indicates the changes from green to red color (Kevrešan et al. 2009). The value b*, indicating intensity of yellow color of the fruit can also be an indicator of both: visual appearance of tomato, as the first property observed by the consumers at the market, and the changes in pigment composition of the fruit. The changes in value a* and b* are presented in Figure 2.

Figure 2. Color measurement value a* and b* during all storage intervals for different packaging materials

Figure 2. Color measurement value a* and b* during all storage intervals for different packaging materialsRegarding the a* value the most intensive increase of intensity of red color was determined for tomato packed in sealed cellophane packages, while application of all other packaging solutions resulted in gradual increase of red color intensity, similarly to the non-packed samples. The least expressed increase of red color intensity was registered in the case of tomato packed in perforate PE.

Measured b* values point out at slight decrease of intensity of yellow color during the initial storage period. During prolonged storage the intensity of yellow color increases with the most expressed ant the most rapid increase in the case of tomato packed in sealed PE packages.

Color differences (ΔEab*) of examined samples packed in different packaging materials with and without perforations were individually calculated in comparison to the initial color of the tomato fruits. The value of ΔEab* indicates the degree to which the color changes are noticeable with bear eyes. According to Young and Whittle (1985) ΔEab* value in the range of 0–0.5 signifies an imperceptible difference in color between two samples, 0.5–1.5 a slight difference, 1.5–3.0 a just noticeable difference, 3.0–6.0 apparent difference. Calculated ΔEab* values are presented in Table 1.

|

Packaging system |

ΔEab* (8th day) |

ΔEab*(14th day) |

ΔEab*(22th day) |

|

Control |

3,6 |

5,6 |

6,8 |

|

Cel+perf |

1,6 |

3,9 |

4,5 |

|

PE+PERF |

3,0 |

4,2 |

6,3 |

|

Celofan |

4,3 |

3,3 |

4,2 |

|

PE |

2,7 |

5,6 |

7,5 |

Obtained results indicate that packaging in sealed cellophane results in the most expressed color change during the initial storage period, while the other packaging materials allow better preservation of color in comparison to non-packed samples. On the other hand, further prolonging of storage of tomato fruits in cellophane does not cause further color changes while all other examined packaging solutions result in additional color change.

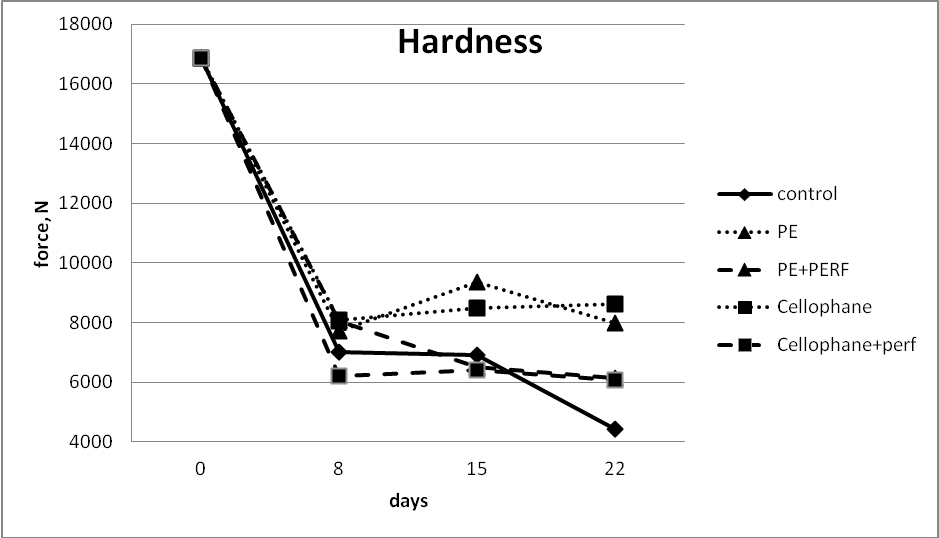

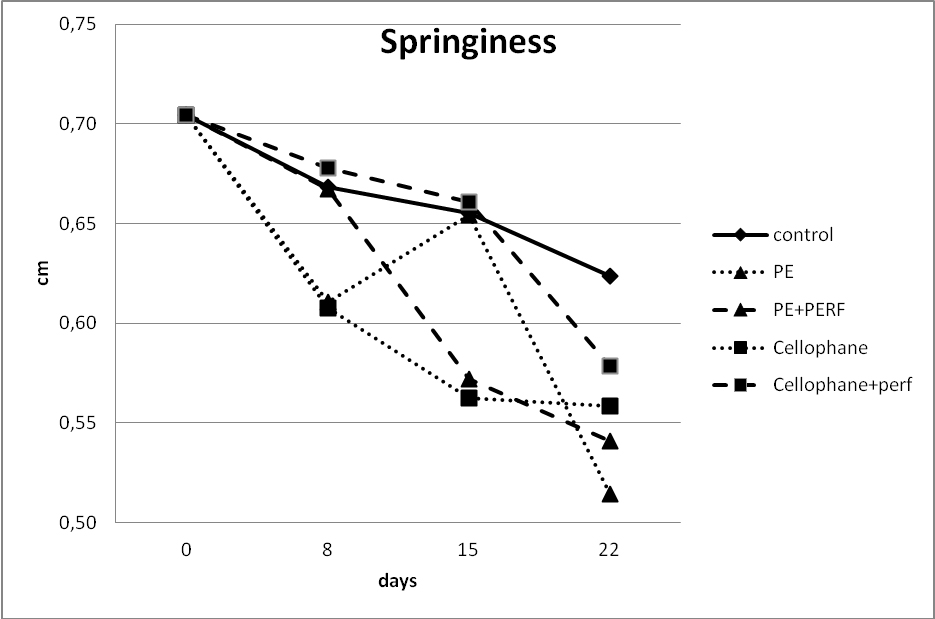

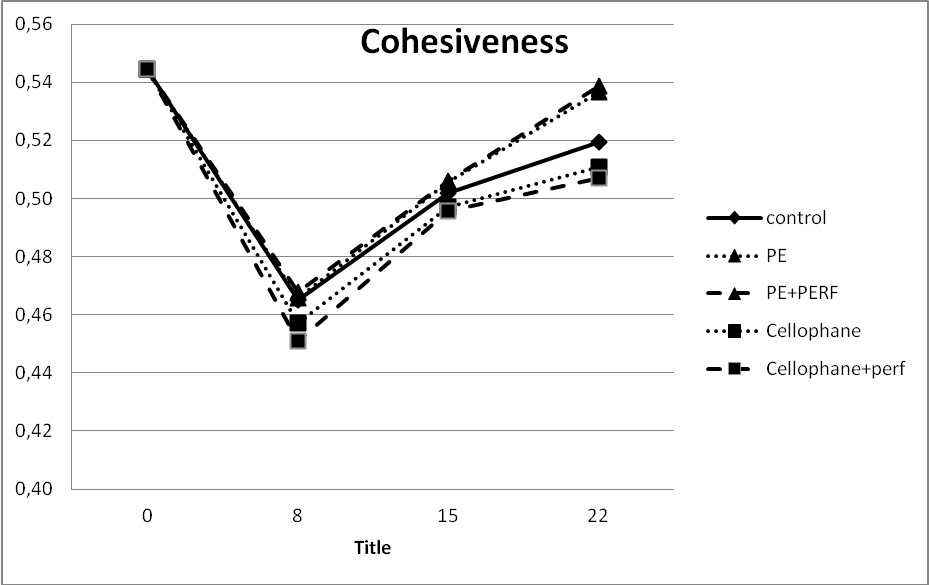

Texture measurements comprise of three parameters significant for characterization of fresh tomato fruits: hardness indicating the resistance of fruit to initial pressure, springiness pointing out at ability of the fruit to recover from the initial pressure and cohesiveness indicating the degree to which internal structure is destroyed by initial pressing of the fruit.

Results for texture measurement are shown in Figure 3.

The most expressed changes in textural properties of tomato during the initial storage period are the decrease of the hardness and cohesiveness of the fruits, which occur independently of the applied packaging solutions. During the prolonged storage period sealed packaging solutions, both PE and cellophane result in better preservation of hardness while PE packages, both perforated and non-perforated result in slightly better preservation of cohesiveness. Sealed packaging solutions result also in more expressed decrease of springiness in comparison to perforated packages and non-packed samples.

Conclusions

Qualitative properties of tomato stored at the conditions characterizing fresh produce market during three weeks storage period of variety Izmir depend on both: selected packaging material and applied packaging solution.Packing of tomato in sealed packages results in lower weight loss and stable weight loss gradient during three weeks of storage. Application of sealed packaging solutions result also in better retention of fruit hardness during prolonged storage, but it also contributes to development of slightly more intensive yellow tone of the fruits and to the more intensive decrease of the springiness in the initial storage period.

Perforated packaging solutions generally result in slower increase of intensity of red color of the fruit in initial storage period in comparison to non-packed and sealed fruits.

Application of PE results in slightly better preservation of cohesiveness of the fruits in later storage periods regardless of applied packaging solution.

АCKNOWLEDGEMENTS

This paper is a result of the research within the project III46001, financed by the Ministry of Education, Science and Technological Development, Republic of Serbia

JOURNAL TOOLS

JOURNAL TOOLS

INSTITUTE

INSTITUTE