INFLUENCE OF pH AND TEMPERATURE ON NONENZYMATIC BROWNING REACTION BETWEEN AFFINED C SUGAR AND AMINO ACIDS

ABSTRACT

Introduction

During the whole procedure of sugar production a wide range of coloured compounds is formed as a result of sugar degradation reactions, pH changes, thermal effects and reaction between amino compounds and carbohydrates. The coloured matter adsorbs on the surface of sugar crystals and occludes within them affecting their quality (Coca et al, 2004). It is known that beet coloured matter is mainly produced during processing from alkaline degradation of invert sugars and melanoidin formation (Godshall, Vercollotti, Triche, 2002). The melanoidins represent the third-stage products of Maillard reaction that occurs between the reactive carbonyl group of the sugar and the amino group of the amino acids (Cämmerer and Kroh, 1995; Clarke et al., 1997).

Sugar beet processing involves a series of consecutive processes, such are extraction, purification, concentration and three-stage crystallization. During all these processes the mechanisms of the degradation of reducing sugars are very complex and result in many intermediate products. Therefore, the difficulties in characterization of colour composition of process samples are overcame by using model colourant systems (Kelly and Brown, 1978/1979) which are created to get information about the browning reaction that has occurred under specific conditions.

White sugar, B sugar, and C sugar are obtained from the crystallization process, where the affined C sugar is a by-product that is characterized with the highest content of coloured matter. Coca et al. (2008) assumed that the arising of coloured matter of affined C sugar was addressed, among other colourants, to the formation of melanoidins due to the relatively high N-compounds content in sugar beet.

The affined C sugar is directed in the first crystallization stage and strongly influences the quality of white sugar contributing to the increase of its coloured matter content (Gyura et al., 2005; Šereš et al., 2004). Since some process parameters, i.e. pH value and temperature influence the formation of coloured matter in sugar beet processing, the objective of this work was to determine the influence of amino acids as well as the changes in pH and temperature on the formation of coloured matter in the Maillard reaction sugar model system (affined C sugar solution with amino acids).

MATERIAL AND METHODS

Materials

The affined C sugar was obtained at the third stage of crystallization from the process of sugar production in Sugar factory “Šajkaška”, Žabalj, Serbia. The basic characteristics of the affined C sugar were determined according to the methods specified by Reinefeld and Schneider (1978).

Thermally induced nonenzymatic browning reaction of affined C sugar

Affined C sugar was dissolved in distilled water and diluted to 40 °Bx dry matter. The mentioned dilution was chosen based on the literature data that indicated that the most efficient formation of coloured matter was in C affined sugar solution with the concentration of 40 °Bx (Gyura, 1992).

50 g of affined C sugar solution was thermally treated at 70 °C and pH=7 during 1200 min and at 80 °C and pH=10 during 1200, respectively.

Thermally induced nonenzymatic browning reaction of affined C sugar and amino acids

The influence of the addition of amino acids (0,01 mol/l) in affined C sugar solution (40 °Bx) on the formation of coloured matter content at different pH values (pH 7 and 10) and temperatures (70 °C and 80 °C) was measured spectrophotometrically at 420 nm and 560 nm using diluted solutions (5 °Bx) and expressed in IU.

Determination of coloured matter

The content of coloured matter (Bl) was determined spectrophotometrically at 420 nm and 560 nm using diluted solutions (5 °Bx) and expressed in IU.

The changes of coloured matter content after the thermal tretatment (DBl) were calculated according to:

where Bli is the coloured matter content after the thermal treatment and B0l is the coloured matter content prior to thermal treatment.

The content of coloured matter formed in min (IJ/min) is calculated according to:

where t is the duration of thermal treatment.

RESULTS AND DISCUSSION

Basic quality parameters of affined C sugar are presented in Table 1. The obtained values were expected for that type of an intermediate product.

|

Parameter |

Affined C sugar |

|

Dry matter content (%) |

98.75 |

|

Sucrose content (°S) |

94.5 |

|

Invert sugar content (%DM) |

0.46 |

|

pH value |

5.97 |

|

Coloured matter content 420 nm (IJ/DM) |

7384 |

|

Coloured matter content 560 nm (IJ/DM) |

1769 |

The nonenzymatic browning reaction in the affined C sugar solution (pH 7, 70 °C) mainly involves alkaline degradation of invert sugars and results in formation of coloured matter (Heitz, 1995). The content of coloured matter in the affined C sugar solution measured at 420 nm and 560 nm increased during the thermal treatment, but the rate of their formation depended on the time of thermal treatment (Fig 1). At the beginning of the treatment the amount of coloured matter formed per min was the highest and decreased over the time (Fig 1).

Fig. 1. Formation of coloured matter (Bv) in affined C sugar solution over the thermal treatment (0-1200 min) at 70 °C and pH 7

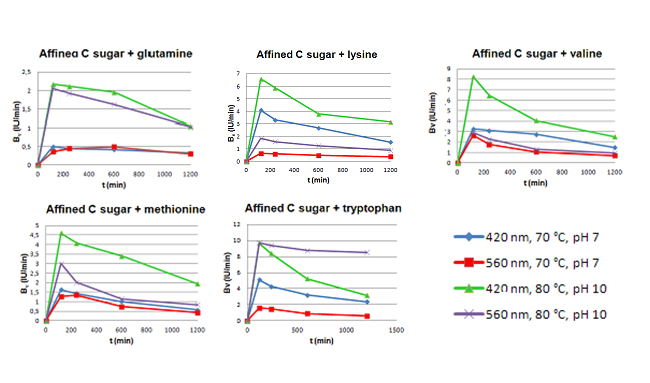

Fig. 1. Formation of coloured matter (Bv) in affined C sugar solution over the thermal treatment (0-1200 min) at 70 °C and pH 7With the aim to investigate the rate of formation of coloured matter in Maillard reaction sugar model system, the affined C sugar solution with amino acids (glutamine, lysine, valine, methionine, tryptophan) was thermally treated (pH 7, 70 °C and pH 10, 80 °C) and the formation of coloured matter over the thermal treatment was monitored. The glutamine was chosen together with other amino acids because glutamic acid represents the major amino acid in sugar beet regarding its content (van der Poel et al., 1998). In water solution both glutamine and glutamic acid are converted into pyrrolidone carbonic acid which is decomposed to produce glutamic acid in alkaline media (Nelson and Cox, 2012).

The addition of amino acids into the affined C sugar solution influenced the degree of browning (Fig 2), i.e. the contribution of Maillard reaction products to the overall browning of the investigated system can be seen from the Figure 2 compared to the Figure 1.

As in the case of thermal treatment of the affined C sugar solution (pH 7, 70 °C), nonenzyimatic browning in Maillard reaction sugar model system was the most intensive at the beginning of the treatment and became less intensive at the end of the examined period (0-1200 min), probably due to the decrease of the reactants.

The presence of glutamine in the model system did not influence the formation of coloured matter, while other examined amino acids increased their production. The effectiveness of amino acids in the formation of coloured matter was as follows: tryptophan > lysine > valine > methionine > glutamine.

pH and temperature influence the rate and extent of nonenzyimatic browning reaction which occurred in in the Maillard reaction sugar model system (Fig 2). It is in line with previously existing statement that the Maillard reaction is influenced by increasing pH and temperature (Kim and Lee, 2008; Martins et al., 2001; Wang et al., 2011).

Conclusions

It was found that the addition of amino acids in affined C sugar solution (Maillard reaction sugar model system) increase the formation of coloured matter compared to their production in affined C sugar solution. The effectiveness of amino acids in the formation of coloured matter was as follows: tryptophan > lysine > valine > methionine > glutamine.

pH and temperature strongly influenced the formation of coloured matter in investigated Maillard reaction sugar model system.

АCKNOWLEDGEMENTS

This paper is a result of the research within the project TR31014 financed by the Ministry of Education and Science, Republic of Serbia.

Fig. 2. Formation of coloured matter (Bv) in affined C sugar solution with amino acids (glutamine, lysine, valine, methionine, tryptophan) over the thermal treatment (0-1200 min) at 70 °C and pH 7 and 80 °C and pH 10

Fig. 2. Formation of coloured matter (Bv) in affined C sugar solution with amino acids (glutamine, lysine, valine, methionine, tryptophan) over the thermal treatment (0-1200 min) at 70 °C and pH 7 and 80 °C and pH 10

JOURNAL TOOLS

JOURNAL TOOLS

INSTITUTE

INSTITUTE