Introduction

Traditional foods are a significant element of the European cultural heritage, which production and sale provide a decisive economic input to many regions (European Commission, 2007). Special characterristics of foods from any region or area are connected to local ingredients and production techniques, which are deeply rooted in tradition and linked to the territory (Aquilanti et. al., 2007). An important group among them are traditional dryfermented meat products. Petrovská klobása is one of them. It is made in an area nearby town of Bački Petrovac in the Autonomous Province of Vojvodina (Northern Serbia). Petrovská klobása is produced exclusively from pork meat, fat and seasonings, in small household enterprises during winter, when temperatures are around 0 °C and lower, using traditional methods. Drying and ripening process lasts about 120 days. Ripened sausage is characterized by specific hot taste, aromatic and spicy flavor, hard consistency and dark red color. These characteristics are largely caused by the addition of a high amount of red hot paprika powder with high capsanthin and capsaicin content in basic formulation of sausage mixture (Kevrešan et al., 2009). Due to its specific and recognizable quality, this product has been protected with designnation of origin (PDO) according to the Serbian legislation (Petrović et al., 2007; Ikonić et al., 2010; Tasić et al., 2010).

Proteolysis is one of the most important biochemical changes affecting proteins during the ripening of fermented sausages. It influences both texture and flavour development due to the formation of several low molecular weight compounds, including peptides, amino acids, aldehydes, organic acids and amines, which are important flavour compounds, or precursors of flavour compounds (Hughes et al., 2002; Dalmis et al., 2008). Activity of present and developed microflora can cause the formation of biogenic amines (BA) which are organic bases produced by decarboxylation of amino acids (Santos, 1996; Shalaby, 1996; Latorre-Moratalla et al., 2008). It is important to monitor the presence of biogenic amines in food since toxicity of these compounds and their association with several health disturbances (Hernndez-Jover et al., 1996; Vidal-Carou et al., 1990).

The objective of this study was to determine whether sausages alternatively dried/ripened in industrial (controlled) conditions would have different nitrogen fraction and BA profiles, when compared to those counterparts from traditionnal/artisanal production. Other parameters related to physicochemical characteristics and proteolysis, such as weight loss, water activity (aw) and pH were also followed up to help on interpretation of results.

MATERIAL AND METHODS

Petrovská klobása dry fermented sausages were manufactured from a mixture of lean minced pork (80%) and pig fat (20%) obtained from carcasses of large white cross breed animals. After grinding the meat and the fat to a size of about 10 mm (with adjustable plate holder diameter set), raw materials were mixed with seasonings (red hot paprika powder, salt, raw garlic paste, caraway and sucrose) for about 10 minutes. The mixture (M) was immediately stuffed in collagen casings (500 mm long and 55 mm in diameter) and raw sausages were entirely processed in traditional smoking/drying room (batch T) or, alternatively, in an industrial ripening room (batch I) during 120 days. The traditional room temperature during drying and ripening ranged from 2.6 °C to 12.4 °C, the relative humidity (RH) ranged from 43.3% to 93.0% while the air velocity ranged from 0 to 0.5 m/s. Batch I sausages were smoked in industrial room for 3 days (10 °C, 90% RH and 0.5-0.6 m/s), dried in the same room at 10 °C, 75% RH and 0.5-0.6 m/s for 27 days and after that ripened in the same conditions but with minimal air circulation.

Samples of batches T and I, picked up at distinct processing stages, included raw meat/fat mixture just after mincing and seasoning operations (0) and three randomly selected sausages with 2, 4, 6, 9, 12, 15, 30, 45 (just batch I), 60, 90 and 120 days of drying/ripening. Nitrogen fraction and BA profiles were determined in raw meat/fat mixture (0) and at the end of drying/ripening process (120).

In order to determine weight loss five sausages from each batch were weighed just after stuffing (0 day). The same sausages were reweighed at the end of production process. The differences in weight are expressed as percentage of the initial weight.

To determine water activity (aw) of samples Testo 650 measuring instrument with a pressuretight precision humidity probe was used (Testo AG, USA).

The pH values of sausages were measured using the portable pH meter (Consort C931, Turnhout, Belgium) equipped with an insertion glass combination electrode (Mettler Toledo Greifensee, Switzerland).

Dry matter (DM) was determined by drying the samples at 103 ± 2 °C to constant weight (ISO 1442:1997).

Determinations of non-protein nitrogen (NPN) and free amino acids nitrogen (FAAN) fractions were carried out according to the methods described in Roseiro et al. (2008). NPN and FAAN contents were expressed as g 100 g-1 dry matter of sample.

Tryptamine, phenylethylamine, putrescine, cadaverine, histamine, serotonin, tyramin, spermidine and spermine were determined following the high-performance liquid chromatography. Sample preparation and extraction were done according to Eerola et al., 1993. HPLC analysis was performed by using a liquid chromatography (Agilent 1200 series), equipped with a diode array detector (DAD), Chemstation Software (Agilent Technologies), a binary pump, an online vacuum degasser, an auto sampler and a thermostated column compartment, on an Agilent, Eclipse XDB-C18, 1.8 μm, 4.6 x 50 mm column (Tasić et al., 2012).

Solvent gradient was performed by varying the proportion of solvent A (acetonitrile) to solvent B (water) as follows: initial 50% B; linear gradient to 10% B in 7.6 min, 10% B to 10 minutes; linear gradient to 50% B in 2 min. System was equilibrated 3 minutes before next analysis. Flow rate was 1.5 mL/min and column temperature was 40 °C. 5 µL of sample was injected. The spectra were acquired in the range 190-400 nm.

Detection limits of the amines were determined to be 0.1 μg/g for putrescine and spermidine, 0.167 μg/g for cadaverine and tyramin, 0.25 μg/g for tryptamine, phenylethylamine and histamine and 0.5 μg/g for serotonin and spermine.

The effects of processing time and processing methodon the variables studied were analysed by two-way ANOVA (Statistica 10 – StatSoft Inc., 2011). The Duncan’s post hoc test was used for comparison of mean values. Differences were considered significant at p < 0.05.

Results and Discussion

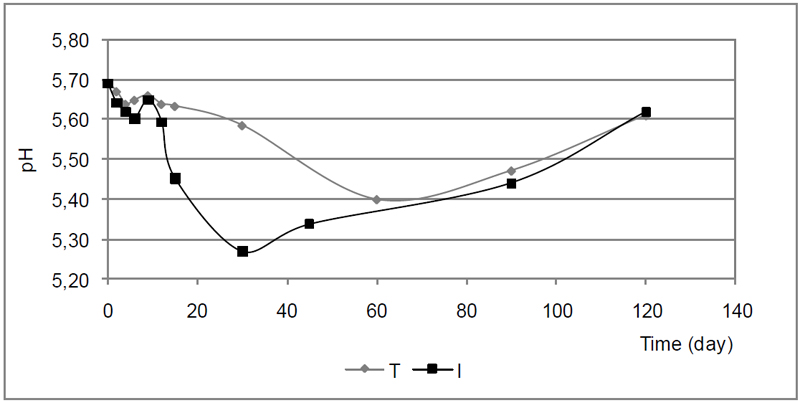

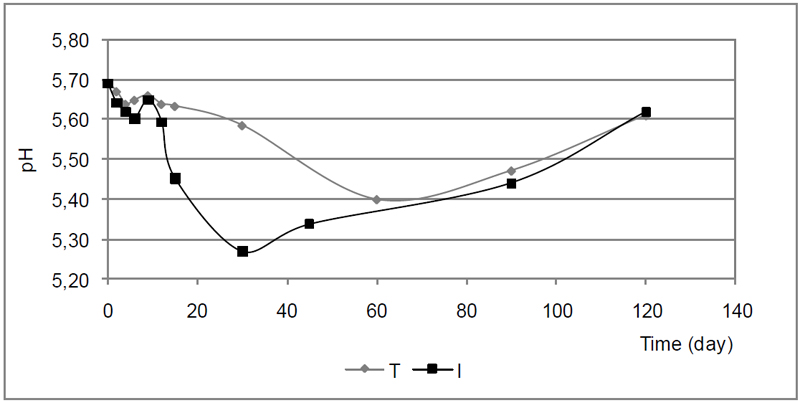

During ripening of Petrovská klobása considerable drying occurred. The changes in aw and weight loss along the ripening period showed the usual trends observed in this type of products (Fig. 1).

The weight loss of sausages averaged over drying type, was significantly higher for products ripened in the industrial room compared with those ripened in a traditional room (47.71% vs. 42.71%, p < 0.05).

The aw diminished from initial values of around 0.95 to 0.82–0.85. These aw values were in agreement with those generally found for various traditional dryfermented sausages (Moretti et al., 2004; Casaburi et al., 2007; Roseiro et al., 2008, 2010).

According to Serbian legislation (Serbian Regulations, 2004) moisture content in dry fermented sausages have to be less than 35%. Sausages from batch T needed 90 days to reach required moisture content, while sausages from batch I reached this value after only 45 days. Both group of sausages were left to ripen until 120th day as it is defined in code of practice of this protected product (Petrović et al., 2007). It resulted in higher dehydration of batch I sausages, i.e. higher weight loss and lower aw values during the whole period of drying and ripening. This trend was determined by the influence of thermo-hygro-metric conditions in industrial room (10 °C and 75% RH).

During the entire drying and ripening process pH values were lower in batch I sausages. These variations were due to the different environmental temperature and relative humidity conditions used in the respective smoking/drying operations, which affected the development of the natural microflora and consequently the intensity of fermentation. It resulted in significant differences (p < 0.05) of pH between batches from 12th to 60th day of production (Fig. 2).

The pH reached its minimal value after 30 days in I sausages while for T sausages that period was twice as long due to very low temperature in traditional room during first two months of production. Either way, pH never fell down below 5.20, being 5.40 and 5.27 in batches T and I respectively, which makes both products to be classified as low acid (Spaziani et al., 2009; Roseiro et al., 2010). At the end of the ripening pH was practically the same in T and I sausages (5.61 and 5.62, respectively), and it almost reached the pH value of unripened meat due to the liberation of peptides, amino acids and ammonia as a result of proteolytic reactions (Bover-Cid et al., 2001).

After 120 days of processing, sausages from batch T had higher nitrogen fractions levels than their counterparts from Industrial production (Table 1). Thus, the effect of the processing method was seen in both NPN and FAAN contents, with differences between batches being significant (p < 0.05). In relation to initial concentrations determined in raw material mixture, contents of these nitrogen fractions increased 15 % more in batch T sausages. Most likely, it was a result of higher aw value in T sausages, during the entire drying and ripening process, which enable more intensive activity of muscle enzymes involved in proteolysis (Toldra, 2006).

Figure 1.

Figure 1. Changes in weight loss (WL) and aw during drying/ripening of Petrovská klobása in traditional and industrial conditions

Figure 1.

Figure 1. Changes in pH during drying/ripening of Petrovská klobása in traditional and industrial conditions

Table 1.Nitrogen fractions content in raw meat/fat mixture and in Petrovská klobásaripened in traditional and industrialconditions.

Time (day) |

0

|

120

|

PT

|

PM

|

PT x PM

|

|

Sample

|

M

|

T

|

I

|

|

NPN

|

0,71 ± 0.02a

|

1,17 ± 0.03c

|

1,07 ± 0.03b

|

*

|

*

|

*

|

|

FAAN

|

0,33 ± 0.00a

|

0,58 ± 0.02c

|

0,53 ± 0.02b

|

*

|

*

|

*

|

Results are given as mean value ± standard deviation

a - c Means within the same row with different superscript letters are different (p < 0.05)

PT - processing time effect; PM - processing method effect

* p < 0.05

Table 2.Biogenic amines content in raw meat/fat mixture and in Petrovská klobásaripened in traditional and industrialconditions.

Time (day) |

0

|

120

|

PT

|

PM

|

PT x PM

|

|

Sample

|

M

|

T

|

I

|

|

tryptamine

|

67.33 ± 6.24a

|

110.69 ± 8.96b

|

55.07 ± 4.85a

|

ns

|

*

|

*

|

|

phenylethylamine

|

67.59 ± 0.62a

|

45.39 ± 8.53c

|

35.80 ± 2.95b

|

*

|

ns

|

ns

|

|

putrescine

|

nda

|

nda

|

6.63 ± 0.23b

|

*

|

*

|

*

|

|

cadaverine

|

nda

|

nda

|

9.56 ± 0.58b

|

*

|

*

|

*

|

|

histamine

|

nd

|

nd

|

nd

|

ns

|

ns

|

ns

|

|

serotonin

|

nd

|

nd

|

nd

|

ns

|

ns

|

ns

|

|

tyramin

|

nda

|

38.23 ± 2.89c

|

15.81 ± 2.84b

|

*

|

*

|

*

|

|

spermidin

|

nd

|

nd

|

nd

|

ns

|

ns

|

ns

|

|

spermin

|

78.7 ± 2.42a

|

65.55 ± 0.75c

|

47.76 ± 3.85b

|

*

|

*

|

*

|

Results are given as mean ± standard deviation

a - c Means within the same row with different superscript letters are different (p < 0.05)

PT - processing time effect; PM - processing method effect

nd - not detected

ns - not significant

* p < 0.05

Content of biogenic amines in raw mixture and in Petrovská klobása ripened in traditional and industrial conditions were determined using HPLC method for analysis and results referred to dry matter are shown in Table 2.

Tryptamine, phenylethylamine and spermine were the biogenic amines determined in all analyzed samples. Values of tryptamine in the raw mixture (M) and in the sausages T and I were 67.33, 110.69 and 55.07 mg kg-1 dm, respectively. There was significant difference (p < 0.05) between M and I and between T and I samples. Content of phenylethylamine ranged from 35.80 mg kg-1 dm in sausage I to 67.59 mg kg-1 dm in the raw mixture, while spermine content ranged from 47.76 mg kg-1 dm in sausage I to 78.7 mg kg-1 dm in raw sausage mixture. Values of phenyl-thylamine and spermine were significantly different (p < 0.05) between all batches, for each amine.

Putrescine and cadaverine were the biogenic amines found only in sausages from I group, with the values of 6.63 mg kg-1 dm and 9.56 mg kg-1 dm, respectively.

Tyramine, reported as the most abundant amine in fermented sausages (Bover-Cid, 2001; Suzzi & Gardini, 2003; Komprda et al., 2004) was found in ripened sausages from both batches, being 38.23 mg kg-1 dm (T) and 15.81 mg kg-1 dm (I), with significant difference (p < 0.05), while in raw mixture this amine was not found.

Histamine, serotonin and spermidine were not detected in any sample. The fact that histamine was not found is very imortant, since histamine is the most important biogenic amine from toxicology point of view (Vidal-Carou et al., 1990; Hernndez-Jover et al., 1996, Shalaby 1996; Latorre-Moratalla et. al., 2008). It can cause urticaria, hypotension, headache, flushing, abdominal cramps, chemical intoxication and other problems for human health (Stratton et al., 1991).

Composition and content of biogenic amines in the raw meat/fat mixture and in the final product produced from the same raw material, dried and ripened in traditional and industrial conditions are differrent since their formation is affected by the complex interaction of factors (Suzzi & Gardini, 2003; Latorre-Moratalla, 2010) what is also confirmed in this study.

Conclusions

The environmental conditions applied during drying and ripening of

Petrovská klobása in industrial room had an influence on physicochemical characteristics, proteolysis and biogenic amines formation. Thus, these sausages (I) had higher weight loss and lower aw and pH values than counterparts ripened in traditional conditions (T). At the end of ripening process (120th day) significantly different (p < 0.05) contents of nonprotein nitrogen (NPN) and free amino acids nitrogen (FAAN) were determined in T and I sausages. Tryptamine, phenylethylamine and spermine were the biogenic amines determined in all analyzed samples, while histamine, serotonin and spermidine were not detected in any sausage. Putrescine and cadaverine were found only in batch I sausages and tyramine was found in ripened sausages from both batches, but not in a raw meat/fat mixture.

АCKNOWLEDGEMENTS

The authors wish to express their sincere gratitude to the Ministry of Education and Science of the Republic of Serbia for its financial support (Project Number: 31032).

Download full article PDF

DOWNLOAD PDF

DOWNLOAD PDF

Figure 1. Changes in weight loss (WL) and aw during drying/ripening of Petrovská klobása in traditional and industrial conditions

Figure 1. Changes in weight loss (WL) and aw during drying/ripening of Petrovská klobása in traditional and industrial conditions Figure 1. Changes in pH during drying/ripening of Petrovská klobása in traditional and industrial conditions

Figure 1. Changes in pH during drying/ripening of Petrovská klobása in traditional and industrial conditions

JOURNAL TOOLS

JOURNAL TOOLS

INSTITUTE

INSTITUTE