ANALYTICAL VALIDATION OF AN ENZIME-LINKED IMMUNOSORBENT ASSAY FOR THE DETERMINATION OF GLUTEN

DOI:

UDK:

JOURNAL No:

Volume 35, Issue 4

PAGES

183-188

KEYWORDS

Gluten, Gluten-free products, Baby food, ELISA, Method validation, Uncertainty

Jovana J. Matić1*, Anamarija I. Mandić1, Bojana M. Beljkaš1, Ivan LJ. Milovanović1, Pavle T. Jovanov1

1Institute for Food Technology, Novi Sad, Serbia

ABSTRACT

Abstract

Gluten is a protein from cereals, which may cause intolerance on food, and can provoke celiac disease. As a routine, gluten is usually conventionally analyzed by enzyme-linked immunosorbent assay method (ELISA). In-house validation of the ELISA screening method for gluten determination was the aim of this work. As certified reference material of gluten is not available, validation was done with spiked samples of gluten free mixture for bread and bakery products and baby food. Validation parameters described in this paper include repaeatability, intra-laboratory reproducibility and accuracy. Uncertainity was calculated from data obtained during validation. The obtained results show that the ELISA method can be used as a screening method for the analysis of gluten in gluten-free products.

INTRODUCTION

Gluten represents the main water-insoluble protein fraction in several cereals such as wheat, rye, oats and barley. Due to the occurence of especially these amino acids in the gluten molecule, this protein can provoke celiac disease (Iametti et al., 2004). Celiac disease is a chronic inflammatory disease of the gastrointestinal tract triggered by dietary gluten in susceptible induviduals. Common symptoms of celiac disease are poor absorbtion of nutrients in the small intestine, fatigue, weight loss and generally poor health. Complete and lifelong adherence to a gluten-free diet is the only accepted tretment which allows patients to lead an otherwise normal life (Sugai et al., 2009). About 0.5-1% of the Western population suffers from celiac disease, which makes it one of the most common food sensitivities worldwide (Van den Broeck et al., 2009). According to unofficial statistical data about 0.44-0.92% of the population in Serbia suffers from celiac disease (www.pks.rs).

According to the Codex Alimentarius recommendations (ALINORM, 08/31/26, Apendix III) and Comission Regulation (EC, No 41/2009) foods labelled as gluten-free must not exceed 20 mg/kg of gluten in food. The food producers in the European Union have to comply with the regulation of Directive 2000/13/EC, as amended by Directive, 2003/89/EC with regard to indication of allergenic ingredients present in foodstuffs.

By regulations in Serbia ("Sl. glasnik RS", br. 35/2008) gluten level in gluten-free products also must not exceed 20 mg/kg. Products declared as a gluten-free should not contain wheat, rye, barley and oat, or if they contain these cereals, gluten must be re-moved by special treatman in order to achieve the concentration level outlined in regulations.

Methods for determining the content of gluten in foodstuffs include enzyme-linked immunosorbent assay (ELISA) (Iametti et al., 2004), High Performance Liquid Chromatography (Wieser et al., 1998.) and electrophoretic methods (Restani et al., 2002). As a routine analysis, gluten is most conveniently analyzed by ELISA tests (Denery-Papini et al., 1999). Gluten proteins are comprised of monomeric gliadins and polymeric glutenins, which are present in approximately equal amounts (Osborne, 1907). Therefore, the content of gluten in food products is usually calculated from the gliadin content.

Due to necessity of the gluten control in gluten-free food products, in-house validation of the ELISA screening method was the aim of this work. As certified reference material of gluten is not available, validation was done on spiked samples of gluten free mixture for bread and bakery products and baby food. The following validation parameters were determined: repaeatibility, in-tralaboratory reproducibility and accuracy. Uncertainity was calculated from data obtained during validation.

MATERIALS AND METHODS

Two different types of samples, gluten-free mixture for bread and bakery products (gluten-free mixture) and baby food, were used for determination of validation parameters. Both samples were declared as the gluten-free products.

Due to lack of gluten certified reference material (CRM), it was necessary to prepare spiked gluten-free samples. Huber (2007) reported that if CRM or control samples are not available, a blank sample matrix of interest can be spiked with a known concentration. The aim of spiking was to obtain content of gluten in finally samples of approximately 20 mg/kg, which is the maximum tolerable level in products declared as gluten-free.

Spiking procedure for gluten-free mixture

Gluten-free mixture was spiked with wheat flour. Content of gluten in wheat flour was 15.3 mg/kg, after dilution with ethanol. Spiking was done by the following procedure: gluten-free mixture and wheat flour were mixed in ratio of 9:1 (w/w); further dillution was 99:1(w/w); and finally this mixture was diluted ten times with gluten-free mixture. Each step of listed procedure was performed with constant stirring.

Spiking procedure for baby food

Concentration of gliadin standard, used as a spike for baby food, was 10.4 mg/kg (determined by six repetitions), which corresponds to the 20.8 mg/kg concentration of gluten. After an adequate sample preparation and dilution with phosphate saline buffer, 75 µl of sample and 75 µl of gluten standard (c=20.80 mg/kg ) was added to the well.

Standard materials

Gliadin standard solutions (5,00; 10,00; 20,00 and 50,00 mg/kg) were used for the preparation of calibration curves. Standards and all reagents from Veratox test kits were stored at 2-8 °C and were warmed to room temperature before use.

ELISA method

The gluten content in the samples was measured by using a commercial Gliadin ELISA kit (Veratox®, Neogen). Veratox for gliadin is a sandwich enyzme-linked immunesorbent assay. Gliadin is extracted from samples with 40% ethanol solution by shaking in a shaker. Extract is diluted in phosphate saline buffer and diluted samples are added to antibody-coated wells where gliadin will bind to the antibody during an incubation period. Any unbound gliadin is washed away and a second antibody, which is enzyme labeled is added. Un-bound enzyme-labeled antibody is washed away and a one step substrate is added. Color develops as a result of the presence of bound-labeled antibody. A stopping reagent is added and the color of the solution is observed. Optical density is measured at 650 nm in a microwell reader (Thermo-labsystem, Thermo, Finland). The optical densities of the controls form the standard curve, and the sample optical densities are plotted against the curve to calculate the exact concentration of gliadin. As approximately 50% of the gluten is available as gliadin, concentration of gliadin multiply by 2 represents the gluten value of the samples (Veratox®, Neogen).

RESULTS AND DISCUSSION

Validation parameters

The following validation parameters were determined: repeatability, intra-laboratory reproducibility and accuracy. The performance characteristics, limit of quantitation and range of quantitation are recommended by manufacturer (Veratox®, Neogen). The limit of quantitation is 5 mg/kg, and this value is described as the lowest concentration point on the calibration curve at which the test can reliably detect gliadin. The range of quantitation is 5-50 mg/kg of gliadin.

For quantitative measurements, recombinant standards are provided to generate calibration curves (Figure 1). Analysis of standards and preparation of calibration curves needs to be done every time when samples are analyzed. The same standards are used during validation.

Repeatability was evaluated under conditions where independent test results are obtained with the same method on identical test items by the same operator using the same equipment within short intervals of time. Spiked samples of gluten-free mixture and baby food were analysed in three repetitions for the calculation of the repeatability.

Intra-laboratory reproducibility was determined from measurement of three samples in various time intervals. Spiked samples were analysed three times and results were measured in three different time periods (0, 15 and 30 minutes).

The accuracy of an analytical method can be described as the closeness of agreement between the true and the value found. The recovery was assessed by adding a known amount of a wheat flour to a gluten-free mixture and gliadin standards solution to a gluten-free baby food.

Repeatability and intra-laboratory reproducibility, expressed by standard deviation and relative standard deviation, and recovery for gluten-free mixture are shown in the Table 1.

Table 1. Validation parameters for gluten-free mixture for bread and bakery products

Gluten-free mixture for bread and bakery products |

||||

|

Repeatability |

Intralaboratory reproducibility |

Recovery (%) |

||

|

Gluten (mg/kg) |

18.6 |

Gluten (mg/kg) |

18.7 |

|

|

Sr (%) |

3.26 |

SR (%) |

2.94 |

87.1 |

|

RSDr (%) |

24.6 |

RSDR (%) |

22.1 |

|

From the results it can be noticed that unusually high standard deviation and relative standard deviation for repeatability and intra-laboratory reproducibility were obtained by analysis of the gluten-free mixture. These results can be explained by inability to prepare adequate homogeneous spiked samples. For the preparation of spiked samples two solid sample were used (gluten-free mixture and wheat flour), and therefore adequate homogeneity of the sample was not achieved. The expected re-covery for average concentration of gluten 18.7 mg/kg is between 80 and 110% (AOAC, 1998). The obtained recovery of 87.1% is in accordance with this standard.

High standard deviations and relative standard deviations are also commonly found during routine laboratory analyses of powdered and solid samples. The reason for this is that gluten is usually not evenly distributed in the whole mass of such samples.

Sumarized results of validation for baby food are shown in Table 2.

Table 2. Validation parameters for baby food

Baby food |

||||

|

Repeatability |

Intralaboratory reproducibility |

Recovery (%) |

||

|

Gluten (mg/kg) |

13.2 |

Gluten (mg/kg) |

13.3 |

|

|

Sr (%) |

1.07 |

SR (%) |

1.05 |

93.6 |

|

RSDr (%) |

5.73 |

RSDR (%) |

5.61 |

|

Analysis of spiked baby food samples were showed lower values of standard and relative standard deviation than the spiked gluten-free mixture. The values of relative standard deviation for repeatibility and intra-laboratory reproducibility are in accordance with the prescribed range of 5.3-7.3%, as also value of recovery between 80 and 110% (AOAC, 1998).

Uncertainty

The uncertainty of measurement is the major unifying principle for data quality. The definition by ISO is that the uncertainty is the parameter, associated with the result of a measurement, that characterizes the dispersion of the values that could reasonably be attributed to the measurand (Gum, 1993).

The uncertainty was calculated according to the instructions of Magnusson et al. (2004).

The Bias is difference between mean measured value from a series of test results and an accepted value. The u(bias) is uncertainty component for bias, and this value is always included in the measurement uncertainty calculations.

For every estimation of the uncertainty from the method and laboratory bias, two components have to be estimated to obtain u(bias): the bias and the uncertainty of the nominal value, u(ref).

For every estimation of the uncertainty from the method and laboratory bias, two components have to be estimated to obtain u(bias): the bias and the uncertainty of the nominal value, u(ref).

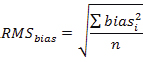

The uncertainty of the bias, u(bias) can be estimated by the following equation:

where

and

Rwis intermediate precision which means that operatorand/or equipment and/or time and/or calibration can be varied, but in the same laboratory.

Combined standard (uc) uncertainties can be summed by taking the square root of the sum of the squares.

And finally expanded (U) uncertainty was calculated using the following equation:

The reason for calculating the expanded uncertainty is to reach a high enough confidence that the true value lies within the interval given by the measurement result ± the uncertainty.

The parameters of uncertainty for the gluten-free mixture and baby food are shown in the Table 3.

Table 3. The parameters of uncertainity for gluten-free mixture and baby food

Parameters of uncertainty |

Gluten-free mixture |

Baby food |

|

Bias |

104.4 |

23.6 |

|

u(bias) |

4.17 |

1.98 |

|

RMSbias |

8.24 |

2.94 |

|

u(ref) |

0.98 |

0.35 |

|

u(Rw) |

4.28 |

2.01 |

|

uc |

9.29 |

3.56 |

|

U (%) |

18.6 |

7.12 |

From the obtained uncertainity results it can be concluded that the expanded uncertainity for gluten-free mixture of 18.6% is much greater than 7.12% for baby food. These differences can be explained with inadequately homogeneity of spiked gluten-free mixture samples.

CONCLUSION

From the obtained results it could be concluded that the ELISA method is adequate for the analysis of gluten in gluten-free products and meets the requirements of validation and quality control purposed for the screening methods.

ACKNOWLEDGEMENTS

This work was supported by the Project No TR-20066, Ministry of Science and Technological Development, Republic of Serbia.

JOURNAL TOOLS

JOURNAL TOOLS

INSTITUTE

INSTITUTE