INFLUENCE OF DIFFERENT FACTORS ON WHEAT PROTEINS QUALITY

DOI:

UDK:

JOURNAL No:

Volume 35, Issue 2

PAGES

47-52

KEYWORDS

wheat, gluten proteins, technological quality

Aleksandra Torbica1*, Jasna Mastilović1

1Institute for Food Technology, Novi Sad, Serbia

ABSTRACT

Abstract

The paper describes the influences of some important biotic and abiotic factors that in recent years have had smaller or greater degree of influence on the deterioration of the quality of wheat in our region. These are primarily: macroelements, high temperature, drought, PADAVINE before and during the harvest, as well as the attacks of field moulds and insects-wheat bug in the first place. Consequences of exposure wheat to deficit or surplus following factors are shown in the deterioration of trading quality in a less degree, while the technological quality of observing the various aspects was certainly deteriorated in larger degree.

INTRODUCTION

It is now clearly established that grain quality is a function of grain composition, principally in proteins, which depends on the genotype and the environment. The genetic effect is mainly reflected by qualitative variation such as protein polymorphism and secondly by quantitative variation of total protein or of different units and subunits. In contrast, the environmental effect (growing season, site, fertilisation) was mainly reflected by the quantitative variation, such as in total protein or protein unit and subunit contents. (Triboï et al., 2000).

Protein composition is a key component of the end-use value for wheat grain. Although the qualitative composition of the grain is genetically determined, the quantitative composition is significantly modified by the growing conditions, and there are significant genotype × environment interactions (Jamieson et al., 2004).

Environmental conditions in influence on proteins

Prior to anthesis, environment affects germination, photosynthesis, tiller formation, and inflorescence development, thereby impactting grain number. After anthesis, environmental conditions primarily affect kernel size and composition (Dupont and Altenbach, 2003).

Temperature influence on proteins

The accumulation of the different protein fractions is highly asynchronous, inferring that the protein composition of the grain changes during grain development. One consequence is that conditions that shorten grainfilling, such as high temperature or drought, affect the balance of protein fractions (Jamieson et al., 2001; Triboï et al., 2003)

Although water deficits severely affect end-use quality for several cultivars of wheat (Guttieri et al., 2000, 2001), little is known about the effect of water deficit and its interaction with temperature on the accumulation of protein fractions. Analysis of the kinetics of accumulation of gliadins and high- and low-molecular weight glutenins in irrigated and non-irrigated felds did not show a signifcant effect of drought (Panozzo et al., 2001). Similarly post-anthesis drought did not affect the rate of accumulation of SDS-soluble and SDS-insoluble polymers (glutenins; Daniel and Triboï, 2002), however, postanthesis drought shortened the period of grainflling before the onset of polymer insolubilization (Daniel and Triboï, 2002; Triboï et al., 2003)

Microelements influence on proteins

a) Nitrogene influence on proteins

The results showed that N supply (fertilisation and site) was the most important environmental factor affecting protein content and composition. The most important effect was quantitative: the total protein, protein unit and subunit contents increased with the supply of nitrogen to the grain. As grain protein increased, the gliadin and glutenin contents and the gliadin to glutenin ratio increased. Gliadin showed a higher correlation with total protein content than glutenin. In the amino-acids composition (g aa:100 g proteins) varies with the N content of the the gliadin:glutenin ratio increases with the quantity of N in the grain;. the concentration of some gliadin bands, measured by electrophoresis and densitometry, changes with the variation in N supply to the grain (Triboï et al., 2000).

a) Sulphur influence on proteins

The effects of S nutrition on dough properties are mainly attributed to its influence on prolamin composition. Moreover, it hase shown that the quantitative distribution of individual gluten protein types is strongly influenced by S fertilization. The increased dough resistance as a result of S deficiency is due to an increase of ratio of high molecular weight glutenin subunit (HMW)/low molecular weight glutenin subunits (LMW) and a consequent shift of polymeric proteins toward higher molecular weight. The decreese in dough extensibility is related to decreeses in the proportion of LMW glutenins and some gliadins, such as a-, b-, and g-gliadins (Shewry and Tatham, 1997). Further, in a work Tea et al. (2003), it was shown using the 34S isotope as a tracer that foliar S fertilizers applied at anthesis stage were incorporated mainly into grain storage proteins, modifying the prolamin composition and their degree of polymerization. In turn these changes influence dough mixing properties. (Tea et al., 2005).

Heat stress influence

Experiments, carried out in conditions close to the Mediterranean climate, indicate that the occurrence of very high temperature in the range 35–40 °C during grain filling sub-stantially affects dry matter and protein accumulation in the different parts of the plant. The formation of the complex protein aggregates responsible for positive dough mixing properties is significantly reduced by very high temperature. When heat shock came late in grain filling, grain yield and protein concentration were not negatively affectted but a dough weakening’ effect, which may reduce the commercial value of the production, is to be expected. (Corbellini et al., 1997).

Field studies indicate that environmental conditions, particularly fertilizer and temperature, affect the amount, composition and/or polymerization of the gluten proteins Effects of temperature on storage protein composition are unclear, and may vary with geno-type. High temperature was reported to increase the proportion of gliadins to glutenins and decrease the proportion of large polymer in flour from several wheat varieties grown in controlled environment experiments Dupont i Altenbach (2003)

According to Jamieson et al. (2001) conditions that shorten the grain filling, such as high temperature or drought, affect the balance of protein fractions .

Moderately high temperatures of 25–32 °C have a positive effect on dough properties, and have been reported to lead to variation of the composition of the gliadin fraction (Daniel and Triboï, 2000; Martre et al., 2006).

In general the gliadins increase dough extensibility and decrease strength. Weakening effects were found to be related to hydrophobicity of different gliadins subunits: ω1>ω2≈α≈β>γ in the Mixograph and ω1≈ω2≈β≈α<γ in the Extensograph1. The γ-gliadins were often associated with loaf volume (Daniel and Triboï, 2000).

The increase in the proportion of gliadin and glutenin was probably related to the decrease in the non-storage protein fraction. Finally, the gliadin to glutenin ratio, reflecting a qualitative change in protein composition, increased with N content per grain, suggesting that as N accumulation increased, gliadin increased preferentially to glutenin (Triboï et al., 2000).

3.4.5. Wheat-bug attack influence

The bug damage of wheat by insects usually by the Eurygaster and Aelia is prevalent in Middle East, Eastern Europe and some Mediterranean regions. Besides the other types of insects, Nysius huttoni in New Zealand, Chlorochroa sayi (Sthal) and orange wheat blossom midge (Stodiplosis mosellana Gehin) in North America have been reported to cause reduced baking quality of wheat. Wheat bug (Eurygaster spp and Aelia spp) has reduced both wheat yield and quality in Turkey and its neighbours for years (Karababa and Ozan, 1998).

Generally, bugdamaged samples had more shrivelled kernels than sound samples. In addition, the test weight, kernel weight and kernel size of the bugdamaged samples were lower than the control samples although the protein content of samples was not increased. Soundness of the grain also directly influences Flour yield and quality. Flour yields of bugdamaged wheat samples decreased while percentage of damage kernel increased as observed in the test weight, the kernel weight and the kernel size. It was observed that bug damaged a†ected the protein quality of wheat more than its protein quantity. The significant diferences were observed in the farinograph parameters except for water absorption. Quality criteria of dough, particularly alveogram values clearly reduced beginning from 3 % bug damage (Karababa and Ozan, 1998).

Flours, having high-protease activity due to preharvest damage to wheat by some Heteropteran insects, are not suitable for breadmaking. These insects (Eurygaster spp., Aelia spp. and Nysius huttoni) attack developing wheat kernels and inject salivary secretions into grain to solubilize nutrients. The salivary secretions contain proteases that break down the gluten structure during mixing and fermentation resulting in poor rheological properties due to weak gluten strength and inferior bread characteristics (Kara et al., 2005).

In Sivri et al. (1998) study, it was shown that Eurygaster maura protease caused progressive decreases in the staining intensities of the bands both in the original gliadin and glutenin patterns of the bug-damaged wheat as incubation time increased. Most of the bands (especially HMW glutenin subunits) disappeared after certain incubation times. However, some of the LMW glutenin subunits were not affected as much as HMW glutenin subunits. Some new bands appeared both at low and high mobility regions of gliadin electrophoregrams. The new bands in the low mobility region are presumably degradation products resulting from hydrolysis of higher molecular weight proteins (glutenin proteins) that do not enter the gel under the conditions of A-PAGE used. it can be concluded that the electrophoretic patterns of the wheat samples with the same level of proteolytic activities were affected differently from the E. maura proteolytic enzymes indicating an intercultivar variation with respect to the resistance of gluten proteins to the enzyme.

Every et al. (1998) suggested that wheat cultivars of generally low baking quality show the effects of bug proteinase in bake testing more readily than cultivars of generally high baking quality.

Vaccino et al. (2006) regard that in the absence of resistant wheat cultivars, producers must rely on chemical control to protect their crop from sun pest infestations.

MATERIAL AND METHODS

Material

The samples were collected from two locations of province of Vojvodina. Cultivars were chosen with respect to the high variations of infestation of insect damage attack and heat-stress. Analyzed samples originated from one wheat production year, which was characterized by heat-stress and presence of high level of wheat-bug damaged kernels, especially in locations 1.

Methods

Electrophoresis of the wheat glutenins and gliadins

Glutenins and gliadins extracted from flour samples and reduced with β-mercapto ethanol were separated by sodium dodecyl sulphate polyacrylamide electrophoresis (SDS–PAGE), on the 12% gel (Kasarda et al., 1986).

For examinations was used Maxi Vertical Dual Plate electrophoresis apparatus (Carl Roth GmbH+Co KG, Germany), using constant buffer temperature of 12 °C and current intensity of 30 mA per gel, with the average analysis duration of about 7 h.

For determination of present proteins bands molecular weights SERVA Unstained SDS–PAGE Protein Marker 6.5–200 kDa Liquid Mix (Serva, Heidelberg, Germany) was used.

Software analysis

After gels staining with Coomassie Brilliant Blue R-250 (Sigma–Aldrich, Co.) and destaining with water, the obtained electro-phoregrams were scanned. High-resolution digital photographs were analyzed by Gelscan 5.1 software package (BioSciTec GmbH, Frankfurt/Main, Germany). Quantitative determination of glutenin and gliadin total amounts for each analyzed sample was done by SDS–PAGE of samples and known quantities of BSA (Serva, Heidelberg, Germany), as standard, under the same conditions.

RESULTS AND DISCUSION

In Tab. 1 are shown data about content of gliadins in seven cultivars from the same year production, which were grown in two different locations.

Table 1. Content of gliadins of cultivars 1-7 in two different locations from the same year of production

The same year of production |

Gliadins content (%) |

||||||

|

Cultivar 1 |

Cultivar 2 |

Cultivar 3 |

Cultivar 4 |

Cultivar 5 |

Cultivar 6 |

Cultivar 7 |

|

|

Locality 1 |

52.80 |

49.36 |

52.99 |

45.84 |

45.75 |

39.95 |

46.59 |

|

Locality 2 |

49.07 |

47.53 |

48.67 |

37.44 |

44.11 |

42.74 |

49.38 |

In relation to the location 2, five of the seven cultivars have increased amount of gliadins on the location 1, which could be explained as consequence of heat stress.

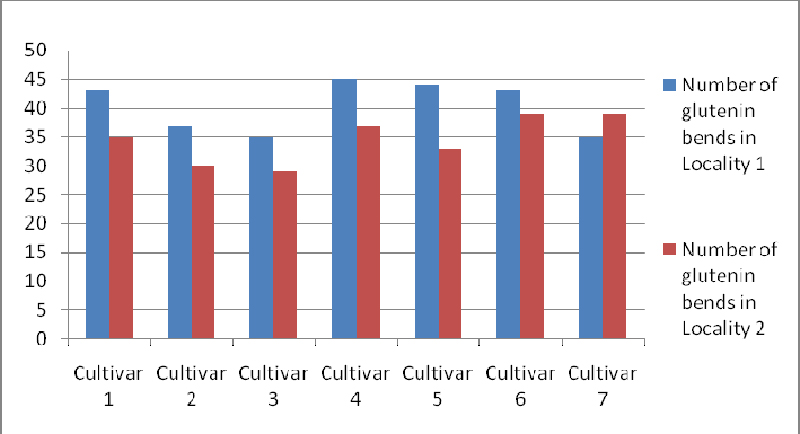

Number of glutenin bands is in the first five examinated cultivars on the location 1 (that characterized by increased content wheat-bug demaged kernels) significantly increased, which indicates on the proteolytic processes.

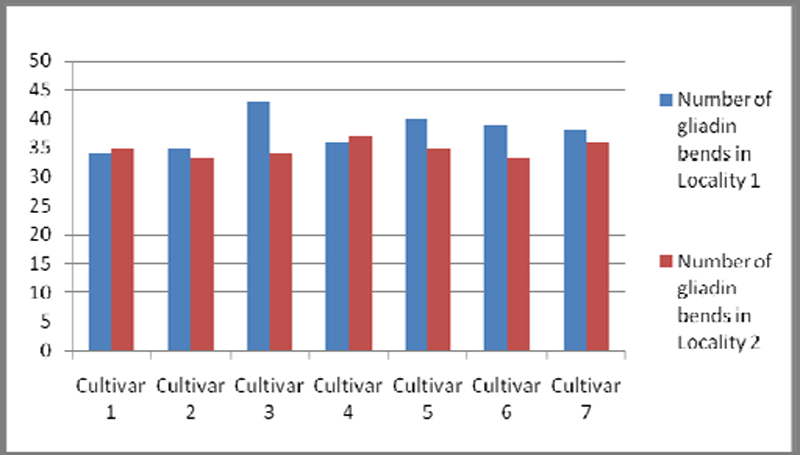

Number of gliadins bands is significantly increased only in cultivar 3, has a small increase for cultivars 5 and 6, while in the other four cultivars, more or less is uniform in the location 1 in relation to the location 2.

Cultivar 4 was the only which could registrated energy on extensigram on the location 1, while on the location 2 only cultivar 7 had energy that could not register. Also, cultivar 7 on the location 1 had gluten index value equal to zero.

CONCLUSION

Gluten complex quality parameters of investtigeted cultivars origin from two locations from the same prodaction years indicate:

- that deteriotation of protein quality had different causes, and

- that resistance to proteolytic process and to heat stress are the specific cultivar properties

ACKNOWLEDGMENTS

This work was supported by the Project No 20139, Ministry of Science and Technological Development, Republic of Serbia.