Pelleting properties and pellet quality of apple pomace

Rade D. Jovanović1, Nataša V. Tolimir1

Bulevar despota Stefana 68b, Serbia

2University of Novi Sad, Institute of Food Technology, 21000 Novi Sad

Bulevar cara Lazara 1, Serbia

ABSTRACT

Apple pomace (AP) is the main by-product of apple juice production. It is a residue after pressing of apples for juice extraction. AP is an organic material, with high moisture and sugar content, therefore its direct disposal on landfills or land spreading causes serious environmental pollution. One of the solutions for further exploitation of AP could be its utilization as animal feed. However, fresh AP is quite perishable, and it must be preserved in order to be stored and used over a long period of time. The aim of this research was to investigate the possibility to transform AP to a stabile form which would be acceptable for feed manufacturers in terms of stability, storage and handling. For this purpose, pelleting process was used and pelleting properties of AP were evaluated. Before pelleting, dried AP was divided into three batches, which were conditioned only by water addition in order to achieve different moisture contents of the material: 10% of moisture for the first batch, 13% for the second batch and 16% for the third batch. According to the obtained values for Pellet Durability Index (PDI) and pellet hardness, pellet quality for all examined AP batches was very high. Increased moisture content of AP led to the reduction in energy consumption of the pellet press, thus providing energy saving in the pelleting process. Pelleting process also caused strong increase of AP bulk density which is positive in terms of transportation and storage.Introduction

An increase in demand for livestock products implies an increase in animal feed production. Animal feed industry is nowadays facing a shortage of quality feeds, which reflects in a rather variable supply, high prices and therefore in a need for alternative feed resources. Many by-products of food processing have a potential to be used as feedstuffs (Dhillon et al., 2013).

Better utilization and evaluation of such by-products would contribute to sustainability of both food and feed production. Apple pomace (AP) is the main by-product of apple juice production. It is a residue after pressing of apples for juice extraction. AP consists of apple peel, seeds, core, stems and pulp, and represents about 25-35% of the weight of the fresh apple processed (Joshi and Attri, 2006; García et al., 2009). Apples are mostly consumed as fresh fruit, but significant amounts are processed into apple juice and other products, generating several million tonnes of AP every year (Bhushan et al., 2008). AP has been regarded as a waste and disposed on land-fills or treated by incineration and composting (Dhillon et al., 2013). The only utilisation currently carried out at the industrial level is pectin recovery (Gullón et al., 2007). Since AP is an organic material, with high moisture (70-75%) and sugar content, it is susceptible to microbial decomposition and uncontrolled fermentation (Bhushan et. al., 2008). Therefore, direct disposal of AP on landfills or land spreading causes serious environmental pollution. Furthermore, safe disposal of AP involves substantial costs relating to its treatment and transportation (Shalini and Gupta, 2010; Dhillon et al., 2013). For these reasons, it should not be considered as a waste, but as a raw material for other purposes. One of the solutions for further exploitation of AP could be its utilization as animal feed.

AP contains small amounts of protein and fat, but it is a good source of sugars, crude fiber, minerals and phytochemicals (Gabriel et al., 2013; Reis et al., 2014). Fresh AP (obtained after pressing of apples) has already been used locally as palatable feed for cattle and sheep (Crawshaw, 2009).

However, since fresh AP is quite perishable, it must be preserved in order to be stored and used over a long period of time. Preservation of AP can be achieved by ensiling or drying (Pirmohammadi et al., 2006). When ensiled with other feedstuffs (corn, alfalfa and wheat bran, sugar beet pulp and brewery spent grain, tomato pomace) AP silage can be successfully used as ruminant feed (Toyokawa et al., 1984; Antov et al., 2004, Abdollahzadeh et al., 2010).

Several authors demonstrated that dried AP could be ground and used as a feed-stuff in rations for both ruminants and non-ruminants. Bae et al. (1994) observed that cows fed total mixed ration containing 39% AP showed increased protein content but decreased lactose content in milk, when compared with cows fed the control diet. Milk fat and solid-not-fat were similar for both diets. According to the research conducted by Bowden and Berry (1958), when dry AP was included in rations for fattening pigs at the amount of 10%, no significant change occurred in daily gain, carcass quality and feed efficiency, compared to the control group fed a standard diet. Being a rich source of polyphenols, AP has a positive impact on animal health.

Gutzwiller et al., (2005) demonstrated that adding 8% of dry AP into weaner pigs’ diet, previously contaminated with Fusarium toxins, counteracted the negative effects of deoxynivalenol on pigs’ growth. Dried AP can be potentially used as a supplement in poultry feed. The results of the study carried out by Zafar et al. (2005) indicate that dry AP can be used safely as an energy source in broiler rations replacing maize by 10% (w/w) without any side-effects on broiler production.

Properties of dried AP could be further enhanced, by processes of grinding and pelleting. Pelleting increases bulk density of the material allowing more efficient transportation, by reducing handling and transportation costs. Additionally, pelleting enhances flow properties of material which is important for transport in conveying equipment, and discharging from silos (Thomas and van der Poel, 1996).

Pelleting also decreases dustiness of material (Abdollahi et al., 2013). AP in pelleted form could be used directly in feeding of ruminant animals or could be transported to the feed mills, where it would be used as a standard feedstuff.

The aim of this research was to investigate the possibility to transform AP, as a very susceptible material, to a form which would be acceptable for feed manufacturers in terms of stability and flowability. For this purpose, pelleting process was used and pelleting properties of AP were evaluated.

Presently, no data on AP pelleting properties are available in the literature but future larger-scale utilization of AP would require such data. Knowledge on pelleting characteristics and quality of AP pellets, such as bulk density, stability during transportation and handling, would be important to feed manufacturers, as well to importers and exporters.

MATERIAL AND METHODS

The research was conducted using AP obtained from fruit processing factory ‘Vino Župa’ in Aleksandrovac, Serbia. It was dried to approximately 10% moisture in a factory’s rotary drum dryer.

Technological processing of AP (grinding and pelleting) and the analysis of the physical quality of pellets were performed at the pilot plant facility and at the laboratories of the Institute of Food Technology in Novi Sad, Serbia.

Dried AP was ground using laboratory hammer mill (Type 11, ‘ABC Inženjering’, Pančevo, Serbia) with 4 mm sieve openings.

All measurements and chemical analysis were done in triplicates, except when stated otherwise.

Chemical analysis

AP was analysed for moisture content (AOAC 950.46), crude protein (Kjeldahl method, AOAC 978.04), crude fat (AOAC 920.39), crude fibre (AOAC 962.10), crude ash (AOAC 942.05), total sugars (Pravilnik, 1988) and reducing sugars (SRPS E.L8.019:1992).

Pelleting

Before pelleting, AP was divided into three batches (30kg each), which were conditioned only by water addition in order to achieve different moisture content of the material: 10% of moisture for the first batch (AP10), 13% for the second batch (AP13) and 16% for the third batch (AP16). Water was added into a double-shaft pedal mixer (Muyang SLHSJ0.2QA, China) equipped with 6 nozzles positioned above mixing pedals which ensures uniform distribution of water.

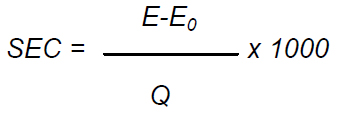

All batches of AP were pelleted on the laboratory flat die pellet press (model 14-175, AMANDUS KAHL GmbH & Co. KG, Germany), equipped with a 18 mm thick die, having a 6 mm opening diameter (L/D - 1:3). Material throughput was 15 kg/h in all pelleting treatments. Specific energy consumption of pellet press (kWh/t) was calculated by using the following equation:

SEC–specific energy consumption (kWt/h)

E–energy consumption during pelleting of the material (kW) (read out from pellet press display)

E0–energy consumption during the idle running of pellet press (kW)

Q–material throughput (t/h)

Temperature of pellet press die was read out from pellet press display.

Before determination of physical quality, pellets were cooled to room temperature using fluidized bed cooler/drier (FB 500x200, Amandus Kahl, Germany) and stored for 24 hours.

Physical quality of pellets

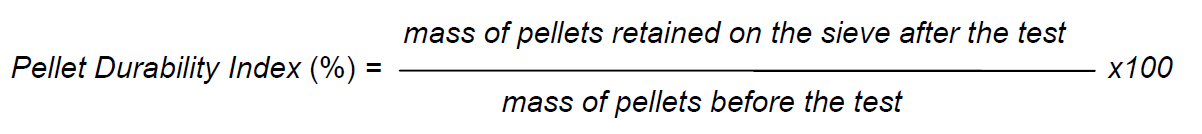

Pellet durability was determined by using a New Holmen Pellet Tester, NHP 100 (TekPro Ltd, Norfolk, Great Britain), which simulates rigorous treatment of pellets by pneumatic handling. Sieved pellet samples (100g) were introduced in a stream of air for 30 s, as it was described by Thomas and van der Poel (1996). In this way, pellets and air were circulated through right-angled bends, impinging repeatedly on hard surfaces, which led to pellet abrasion. After the treatment, the samples were sieved again. The sieve with the 4.8 mm sieve openings (approximately 80% of the pellet diameter) was used. Pellet durability was expressed as the Pellet Durability Index (PDI), and calculated by using the following equation:

mass of pellets retained on the sieve after the test

Pellet hardness was determined with manually operated compression pellet tester “Pellet Hardness Tester“, AMANDUS KAHL GmbH & Co. KG, Germany, by measuring the force of the first fracture of individual pellets. Twenty pellets of approximately equal length, from each batch were tested. The results of the measurements are expressed as Kahl hardness.

Bulk density of ground and pelleted AP was measured with a bulk density tester (Tonindustrie, West und Goslar, Germany).

Statistical analysis

The one-way ANOVA analysis was performed to evaluate data differences between AP batches using Statistica software version 12 (Statistica, 2013). Significant differences were analyzed by Tukey HSD tests.

Results and Discussion

Chemical composition of AP varies significantly, since it is affected by apple cultivar, growing region, climate and processing (Zafar et al., 2005). The results of the chemical analysis of AP are given in Table 1. As it can be seen, major constituents of apple pomace are crude fibre and sugars, while levels of protein and crude fat are very low. These results are comparable with the data presented by Ganai et al. (2006), Joshi and Attri (2006) and Dhillon et al. (2013).

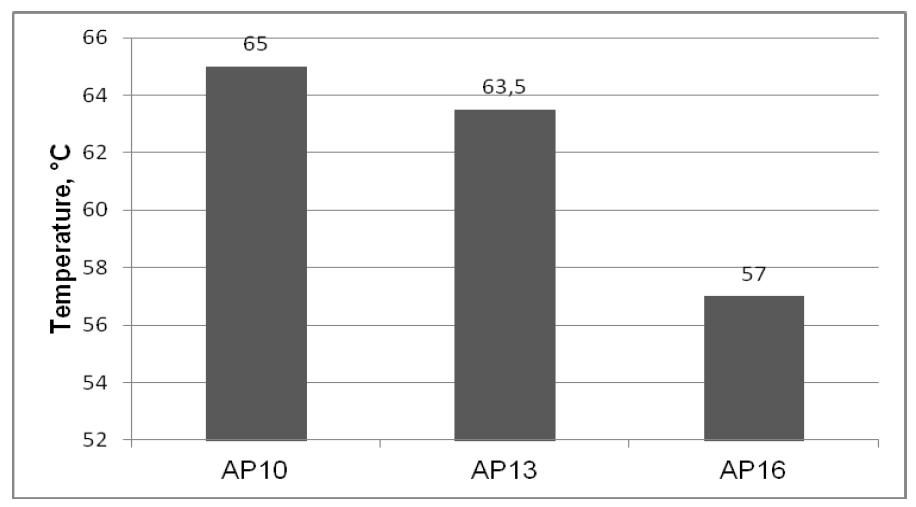

During pelleting, the increased moisture content caused a decrease in the temperature of the pellet press die (Figure 1). According to Vukmirović et al. (2010), this can be explained by lower friction in die channels, since water has a lubricating effect and decreases friction between surface of die channels and pelleted material. When looking at bulk density values (Figure 2) it can be seen that treatment AP10 had significantly lower bulk density (p<0.05) compared to treatments AP13 and AP16. On the other hand, there was no statistically significant difference in the bulk density of the batches AP13 and AP16. However, much more important was to compare bulk density before and after pelleting. Bulk density of pelleted AP was almost twice as high than it was before pelleting.

Temperature of pellet press die and specific energy consumption (SEC) can be used as an indicator of the friction forces in the die openings of the pellet press. Similarly to results for die temperature, an increase in moisture content of AP before pelleting decreased the friction in die channels due to lubricating effect of water, which resulted in significantly lower energy consumption of the pellet press (Table 2). Similar results were presented by Fairchild and Greer (1999) and Moritz et al. (2003) who observed a decrease in pellet mill energy consumption when moisture was added to the pelleting mash at the mixer.

Lower friction during pelleting of AP with higher moisture contents resulted in lower pressures in the die openings. This caused significant reduction of pellet hardness with increasing the moisture content of AP (Table 3). Thus, positive effect of increased moisture content of AP was the reduction in energy consumption of the pellet press, which provides energy saving in the pelleting process. Additionally, softer pellets, obtained by pelleting AP with higher moisture content, would be chewed by ruminants more easily. Also, softer pellets would be easier to grind in the process of production of poultry or pig feed.

PDI is the most important quality parameter, with low pellet durability causing major damage of pellets during transportation and handling. Pellet quality for all examined AP batches was very high, since the obtained values for PDI were above 99%, i.e. there was almost no abrasion. Such results can be explained by the high sugar content in AP. During pelleting, sugars are solubilized. As a result of sugars’ recrystallization during cooling, binding between particles takes place due to the formation of a solid bridge (‘solid-solid interactions’) (Thomas et al., 1998). Furthermore, high fibre content in AP probably contributed to the pellet dura-bility. Fibre may be useful in the pelleting process, since fibre can entangle and fold between different particles or strands of fibre (Rumpf, 1957). The highest PDI was obtained for the batch AP16, which had the highest moisture content. This is most likely because sugars were solubilised to a greater extent.

Results are given as mean ± standard deviation (n = 3)

Figure 2. Bulk density of the non-pelleted AP and AP pellets|

|

Moisture |

Crude protein |

Crude fat |

Crude fibre |

Crude ash |

Total sugars |

Reducing sugars |

|

AP |

7.96±0.33 |

5.9±45 |

2.26±0.12 |

20.76±0.27 |

2.06±0.04 |

30.29±0.12 |

27.12±0.43 |

Results are given as mean ± standard deviation (n = 3)

*Wet weight basis

|

|

|

AP10 |

AP13 |

AP16 |

|

|

|

SEC*, kWh/t |

34.15±4.76a |

25.87±4.03b |

22.71±3.52c |

Results are given as mean ± standard deviation (n=25)

a,b,c Means with different letters in the same row for each sample are statistically significantly different

*SEC for the batch AP10 was statistically significantly different compared to the SEC for the batches AP13 and AP16, at the level p<0.01. Differences in SEC between batches AP13 and AP16 were statistically significant at the level p<0.05

|

|

|

AP10 |

AP13 |

AP16 |

|

|

|

PDI, % |

99.13±0.24а |

99.55±0.27а |

99.74±0.01а |

|

|

|

Pellet hardness, KH* |

12.22±2.28a |

9.66±1.34b |

6.06±1.07c |

Results are given as mean ± standard deviation (n=15)

a ,b,c Means with different letters in the same row for each sample are significantly different (p<0,01)

*Kahl hardness

According to Wood (1987) and Vukmirović (2015), there is a positive correlation between pellet hardness and pellet durability. Consequently, it could be expected that an increase in moisture content of AP, which decreases pellet hardness, could also cause decrease of PDI. Nevertheless, in this research PDI was very high in all pelleting treatments, regardless of moisture content before pelleting. This was probably because low moisture content caused higher friction and pressure in the die holes. This resulted in decrease of distances between particles thus enhancing particle binding by solid-solid interactions (Thomas and van der Poel, 1996; Vukmirović, 2015). On the other hand, higher moisture content of AP provided more bonds between particles due to capillary sorption and caused better compression characteristics of material due to chemical changes of AP components (Thomas and van der Poel, 1996). Consequently, there were no significant differences between PDI values when AP batches with different moisture contents were pelleted.

Conclusions

From the obtained results it can be seen that AP is characterized by high pelletability, since it was shown to have very good pelleting properties and high quality of pellets was obtained. Addition of water in liquid form is sufficient for the successful pelleting of AP, i.e. there is no need for steam conditioning of AP before pelleting. This will decrease production costs com-pared to situation when water is added in the form of steam. Initial moisture content of 10% would be sufficient for producing high quality AP pellets, but in terms of energy saving, higher moisture content of the initial material (up to 16%) would be recommended. Moisture content of dried AP is usually below 10%. In order to decrease pellet press energy consumption, drying to higher moisture levels (approx. 16%) could be recommended. This will result in decrease of energy consumption for drying. Increasing the moisture content of AP resulted in softer pellets that would be more easily consumed by ruminants or more easily ground during preparation of poultry or pig feed. Pelleting process caused strong increase in bulk density of AP which is positive in terms of transportation and storage.

In addition to using pelleted AP as a standard feedstuff, good pelleting properties of AP suggest that it could also act as binding agent with a potential to facilitate pelleting process and to improve pellet quality when AP is included in feed mixtures, but further research on this matter is needed.

АCKNOWLEDGEMENTS

This paper is a result of the research within the project III 46012 - Study of modern biotechnological methods in the production of animal feed in order to increase competitiveness, quality and safety of the feed, financed by the Ministry of Education, Science and Technological Development, Republic of Serbia.