Breadmaking potential and proteolytic activity of wheat varieties from two production years with different climate conditions

Jelena M. Tomić1*, Aleksandra M. Torbica1, Ljiljana M. Popović2, Slađana M. Rakita1, Dragan R. Živančev1

Bulevar cara Lazara 1, 21000 Novi Sad, Serbia

2University of Novi Sad, Faculty of Technology, Bulevar cara Lazara 1,

21000 Novi Sad, Serbia

ABSTRACT

The wheat flour represents a complex system whose quality is influenced by several factors such as genotype, growing conditions and the complex interaction of genetic and environmental factors. In recent years, wheat quality fluctuation has become a major issue for millers and bakers. Requirements of bakery industry for providing wheat flour of uniform quality impose the need for further investigation in direction of monitoring/improving wheat flour quality. Therefore, the objective of the present study was to evaluate wheat varieties, grown in different locations, by breadmaking potential and proteolytic activity in dependence of climate conditions. Wheat flour of four wheat varieties (Pobeda, Zvezdana, Gordana and Apache), from seven locations in Serbia characterized by different climatic conditions in two production years, were used in this study. The analyses included a determination of proteolytic activity and the rheological properties of dough. Rheological properties of wheat flour dough were determined by Gluten index and Brabender equipment (Farinograph, Extensograph and Amylograph). The studies ended with a trial baking and estimation of textural properties of obtained bread. Large variability for all attributes evaluated was observed, with wider ranges in quality parameters across varieties than among growing locations. Wheat flour samples from 2012 production year were characterized by inferior quality parameters. Proteolytic activity and bread specific volume values for 2012 production year were significantly lower compared to 2011. These results indicate that level of proteolytic activity was under optimum for obtaining bread with higher specific volume.

Introduction

The modern baking industry requires a high level of uniformity in wheat flour quality that satisfies the requirements of automatic processing. The achievement of these demands is very difficult because the wheat quality is influenced by several factors such as genotype, growing conditions and the complex interaction of genetic and environmental factors (Vázquez et al., 2012). Bearing in mind the demand of bakery industry, understanding these effects is of great importance primarily for the development of wheat varieties with specific and consistent quality traits. Many studies have been conducted in an attempt to explain variations in the quality of wheat as a function of genetic variability, growing conditions and their interactions (Preston et al., 2001; Zhang et al., 2004). The influence of mentioned factors is manifested through changes in wheat grain, primarily on starch (a key factor for yield) and protein (a critical factor for the quality) component (Altenbach, 2012).

Relations between environmental conditions, yield and quality of wheat are very complex as evidenced by the numerous scientific researches (Zhang et al., 2004; Souza et al., 2004; Finlay et al., 2007). There are certain number of contradictory studies about which factor (genotype or environment) is more important for most quality characteristics. Many studies indicate that the magnitude of the effect of genotype and environment differs among quality parameters (Denčić et al., 2011; Wrigley, 2007).

There are different methodological approaches for defining the characteristics of wheat flours. Commonly used methods for assessing the wheat quality are empirical rheological methods such as Farinograph, Mixograph, Extensograph, Alveograph and Amylograph. During the last few years, the relatively new rheological device Mixolab has been largely used for fast wheat quality assessment (Dapčević et al., 2009). Although the wheat quality assessment is based on information obtained through the sensory, chemical, rheological and technological analyses, the baking test remains a key method to evaluate flour quality (Gélinas and McKinnon, 2011).

Regarding the proteolytic activity, their impact on the quality of wheat flour dough due to changes in the protein gluten has been the subject of considerable research and controversy (Kruger et al., 1977; Dominguez and Cejudo, 1996; Calucci et al., 2004). There is a general belief that the proteolytic activity in sound wheat is very low and, as such, has little signifycance in the change of wheat flour bread-making potential (Rani et al., 2001). On the other hand, increased proteolytic activity in the germinated wheat leads to a reduction in the gluten quantity and its poorer rheological properties, as shown by a decrease in the water holding capacity of flour, shorter dough development and stability period and an increased softening (Dojczew and Sobczyk, 2007).

In recent years, as a consequence of altered climate conditions, quality fluctuation has become a major issue which is reflected through the changes in protein, carbohydrate and enzyme complex of wheat grain. Consequently, a new climate trends impose the need for further investigation in direction of monitoring/improving wheat flour quality.

The objective of the present study was to evaluate wheat varieties, grown in different locations, by breadmaking potential and proteolytic activity in dependence of climate conditions.

MATERIAL AND METHODS

Material

Four wheat varieties of Triticum aestivum Pobeda (Pob), Zvezdana (Zve), Gordana (Gord) and Apache (Ap) grown in two production years (2011 and 2012) at seven locations in Northern Serbia were selected for the study. Pobeda, Zvezdana and Gordana were bred by the Institute of Field and Vegetable Crops, Novi Sad, Serbia, whereas Apache was bred by Limagrain, Chappes, France. The samples were cleaned and tempered according to the AACC 26-10.02 and milled to laboratory flour using a Bühler MLU 202 mill (Bühler, Uzwil, Switzerland) according to the AACC 26-31.01 (AACC, 1999).

Meteorological data for period from May to July (from anthesis to harvest maturity) were collected by automatic hydrological stations (provided by the Agricultural Advisory Services). The 2011 production year was characterized by lower temperatures, drier conditions with an average growing season temperature across the locations from 16.6 °C (for May) to 23.2 °C (for July). Maximum daily temperatures, for the May and July, were above 31 °C and 38 °C, respectively. The number of days with maximum temperatures above 30 °C for the tested locations ranged from 12 to 26. The 2012 production year was much warmer, with an average growing season temperature range across the locations of 25 (for May) to 32 °C (for July). June and July were characterized by deficient precipitation with extremely high maximum temperatures. Maximum temperatures were above 35 °C. The number of days with maximum temperatures above 30 °C was markedly higher than in the 2011 production year (from 31 to 41).

Rheological properties of the flour samples

The rheological properties of wheat dough were determined using the Brabender Farinograph according to ICC 115/1, the Brabender Extensograph according to ICC 114/1, the Brabender Amylograph according to ICC 126/1, the Chopin Alveograph according to ICC 121 (ICC, 1992).

Gluten index (GI)

GI was measured in two different ways: according to the ICC standard method 155 (ICC, 1994) and after incubation of a dough ball at 37 °C for 90 min (GI (37 °C)) (Torbica et al., 2007).

Measurement of proteolytic activity

Proteolytic activity of wheat flour was determined as described by Calucci et al. (2004) and Strelec et al. (2007) with some modifications. Flour (2.5 g) was suspended in 5 ml sodium acetate buffer (50 mM, pH 5.0). The proteolytic activity was measured by using 1% (w/v) hemoglobin (Hb) as a substrate. The reaction was initiated by adding flour extract (600 µL) in 2.7 mL of Hb and after incubation at 45 °C for 1 h terminated by adding 25% (w/v) trichloroacetic acid (TCA). After the centrifugation (10 min at 15000 g), 0.5 mL of the supernatant was utilized to determine the TCA-soluble products by the Lowry method (Lowry et al., 1951). At least three replicates were performed for each analysis.

Breadmaking procedure

Baking trials were conducted under laboratory conditions. For 300 g tin bread making method, the test baking formula was: 300 g of flour (14 g/100 g moisture basis), 2% fresh compressed yeast (flour basis) and 2% salt (flour basis). The total volume of water required for dough consistency of 400 BU is calculated on the basis of farinograph data: water absorption and the degree of softening according to the Serbian official methods (1988). After mixing for 5 minutes, dough was fermented for 120 min at 30 °C and 75% relative humidity (RH), with punches after 60 and 90 min. The fermented dough was divided into 130-g portions and proofed for another 70 min at 30 °C and 75% RH for final proofing. Doughs were baked for 15 min at 220 °C. After cooling at room temperature for 1h, the loaves were kept in a climate chamber for 23h in controlled conditions of temperature (22 ± 0.7 °C) and humidity (75 ± 0.5%).

CHARACTERIZATION OF BREAD

Specific volume

The breads were weighed after cooling for 1h and their volume (cm3) was determined by millet displacement method. The specific volume (cm 3/g) was calculated as loaf volume/bread weight.

Texture measurements

Bread crumb firmness was measured following the AACC (74-09) standard method on a TA-XTplus Texture Analyser (StableMicro System, Godalming, Surrey, UK) using a 36-mm diameter probe, 30-kg load cell on 12.5-mm thick slices. For each firmness measurement, three samples were used. The analysis of texture was carried out 24h after baking.

Statistical analysis

The experimental data collected was analyzed using the analysis of variance (ANOVA). The comparison among means was done by the Fisher’s LSD test regarded significant at p<0.05. Statistical method was performed using the Statistica 12.0 software (Statsoft, Tulsa, OK).

Results and Discussion

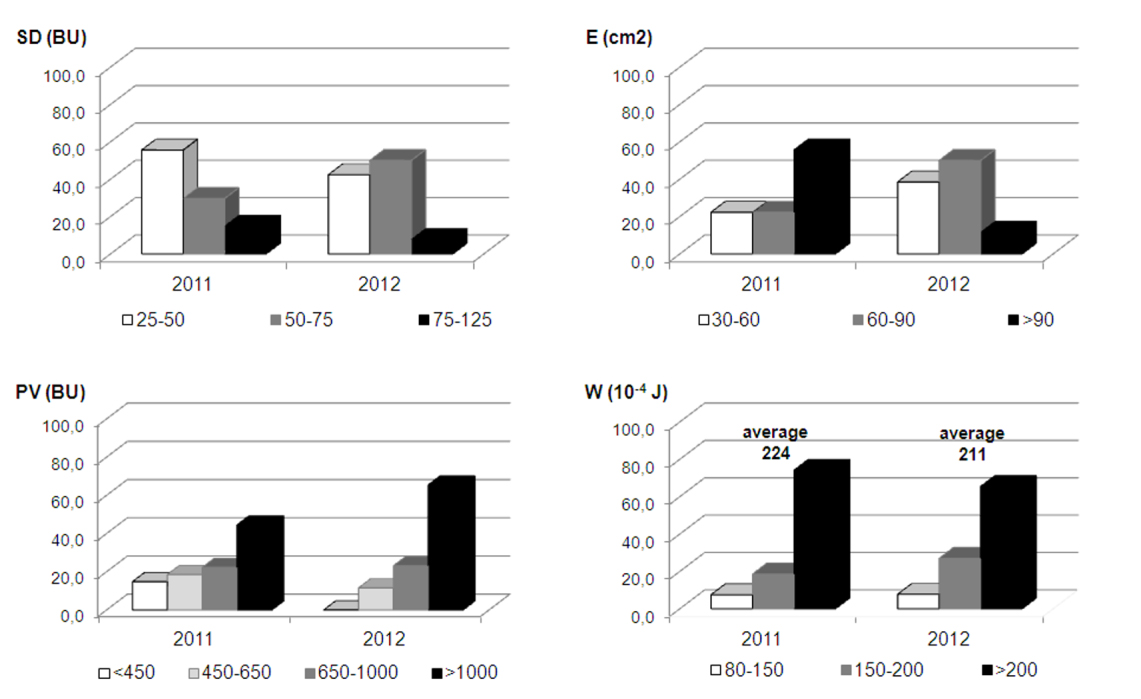

In order to evaluate the frequency of certain quality levels of the analyzed wheat flour samples, shares of selected quality range were graphically presented as well as their average values for each year individually for the following parameters: SD- Degree of softening obtained by Farinograph (BU); E- Energy obtained by Extensograph (cm2), PV- Peak viscosity obtained by Amylograph (BU) and W- Deformation energy obtained by Alveograph (x10-4 J) (Figure 1). These parameters are commonly used to estimate the wheat flour quality for a particular purpose.

Compared to the 2011 production year, wheat flour samples from 2012 were characterized by inferior quality parameters obtained by Farinograph and Extensograph. In the 2011 production year, there was a higher proportion of samples with lower degree of softening (SD) and higher values of energy (E).

Regarding the alveograph parameter (W), differences between flour samples from the two production years were much smaller, but generally the average value of this parameter indicate a good technological quality (more than 50% of flour samples had values of W above 200) (AbuHammad et al., 2012).

All tested wheat flour samples exhibited markedly high level of amylograph peak viscosity (PV) regardless of the production year, which were above the optimum suitable for processing in baking industry (>650). Within the tested production years, samples from 2012 production year were characterized by significantly higher PV values, i.e. 75% of flour samples had PV value above 1000 BU. Since the 2012 production year was characterized by higher temperatures during the growing season (from anthesis to harvest) and higher number of days with temperature above 30 ⁰C, it can be assumed that these unfavourable conditions caused the changes in the synthesis of enzymes, primarily amylases (Johansson et al., 2013). On the other hand, a different degree of shortening of the biosynthesis duration of proteins and starch might have happened as well.

Changed properties of the starch-amylose complex of wheat samples are reflected through differences in the size of starch granules and their morphology, as well as ways of their formation in the endosperm, which could have an influence on peak viscosity values (Thitisaksakul et al., 2012). Based on these findings it can be assumed that high PV values could be the consequence of the way of packing starch granules and their size, not exclusively the consequence of amylolytic activity. There are some studies which indicate that wheat flour showed a relatively good breadmaking potential despite a comparatively low PV values (Ichinose et al. 2001). However, other quality parameters in our study showed relatively good processing quality of the wheat flour samples indicating that redefinition of the importance of common technological parameters is necessary. As a consequence of altered climatic conditions, the same values of standard quality parameters of wheat and wheat flour have a different meaning today than few decades ago.

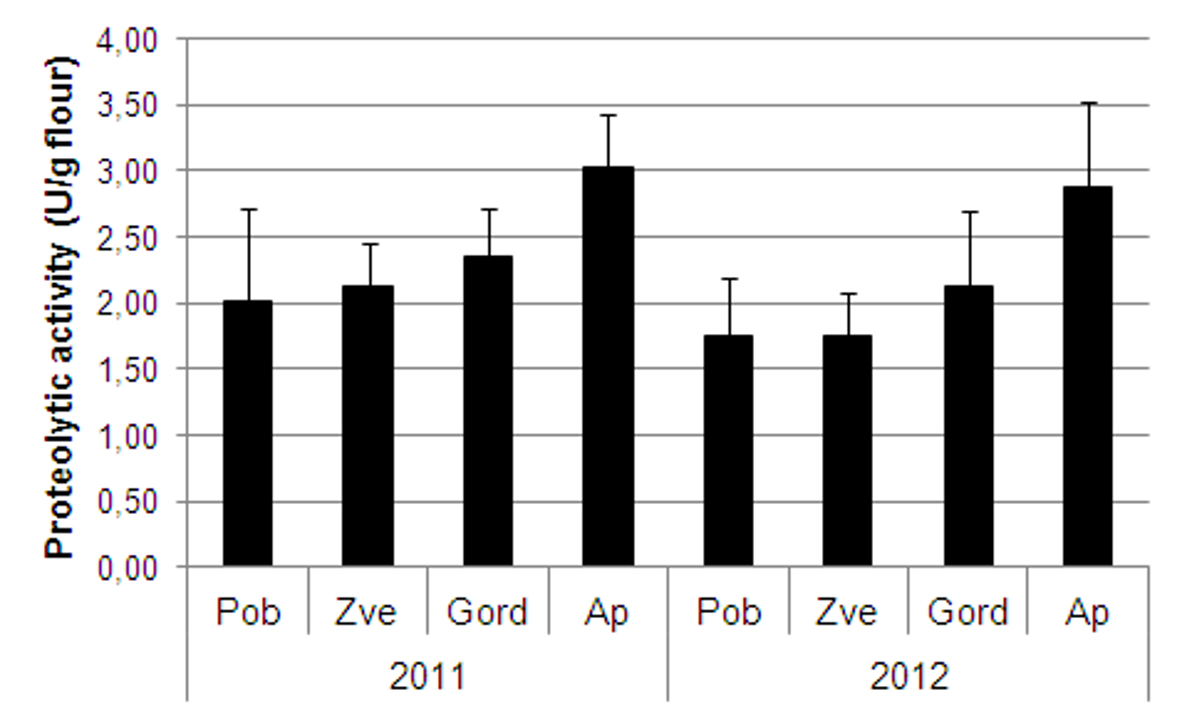

Figure 2 shows the proteolytic activity of all tested wheat flour samples in two production years. The obtained results showed that variety, growing location as well as production year had strong influence on the proteolytic activity. High values of standard deviation indicated the influence of different growing locations. The proteolytic activity was in the range between 1.05-3.77 U/g. It could be noticed that this parameter was primarily varietal feature but it could not be ignored the impact of climate that prevailed during the tested two years. The total proteolytic activity was significantly higher for the 2011 compared to the 2012 production year. Regarding the varieties, the variety Apache was clearly separated by higher values of this parameter regardless of production year.

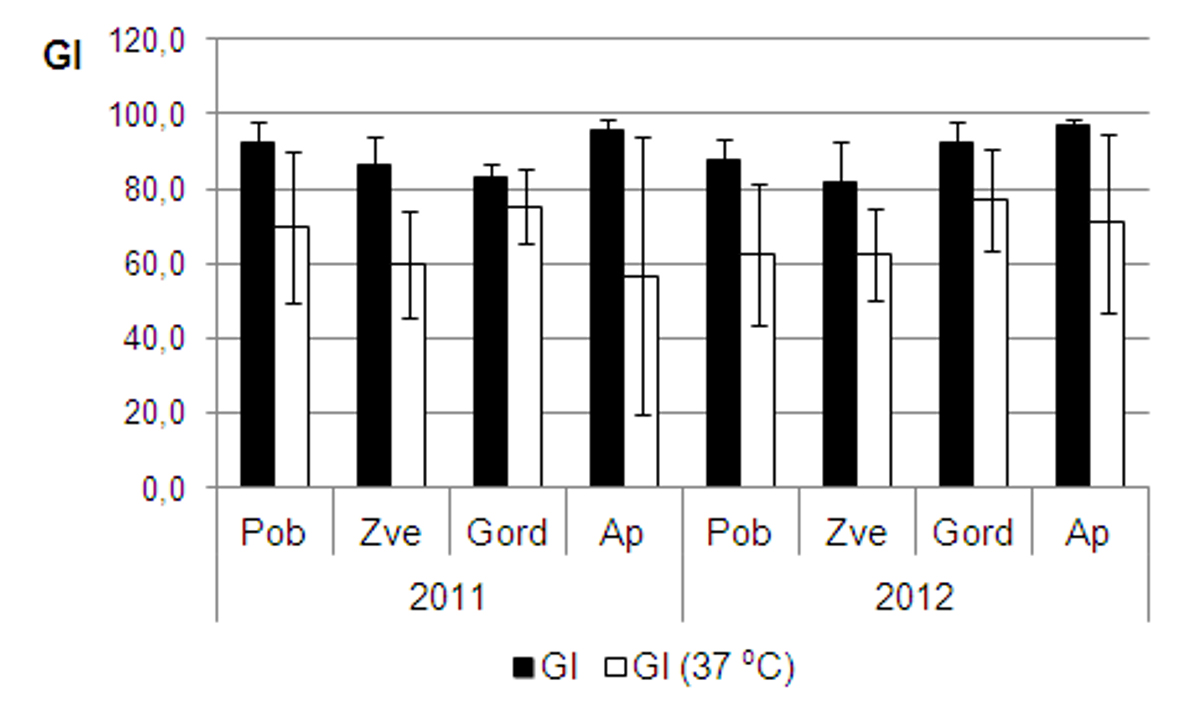

Figure 3 shows the results of gluten index (GI) obtained for all tested wheat flour samples performed without previous incubation and after incubation of dough ball at 37 °C. The values of GI as an indicator of gluten strength showed strong influence of variety. GI obtained without previous incubation of dough ball provides information about the rate of high/low molecular weight proteins i.e. provides information about the strength of gluten (Collar et al., 2007), while the GI values obtained with previous incubation at 37 °C indicate the degree of gluten hydrolysis as a consequence of increased proteolytic activity. The average values of gluten index (83-95.7) for all examined varieties indicated different gluten strength (from strong to very strong) and they were considered to be suitable for obtaining optimum quality bread (Har Gil et al., 2011). Considering the values of standard deviation it could be noticed that the GI parameter obtained with the standard procedure was not influenced by growing locations. That was not the case for GI values after incubation at 37 °C. High standard deviation values, especially for Apache variety indicated relatively weak resistance of varieties to the prevailing microclimate conditions, which contributed to the variation of the tested parameter. These values (GI 37 °C) were lower than those obtained by standard GI procedure. Apache variety from 2011 production year showed the greatest decrease of GI values after incubation at 37 °C which was in accordance with results of proteolytic activity.

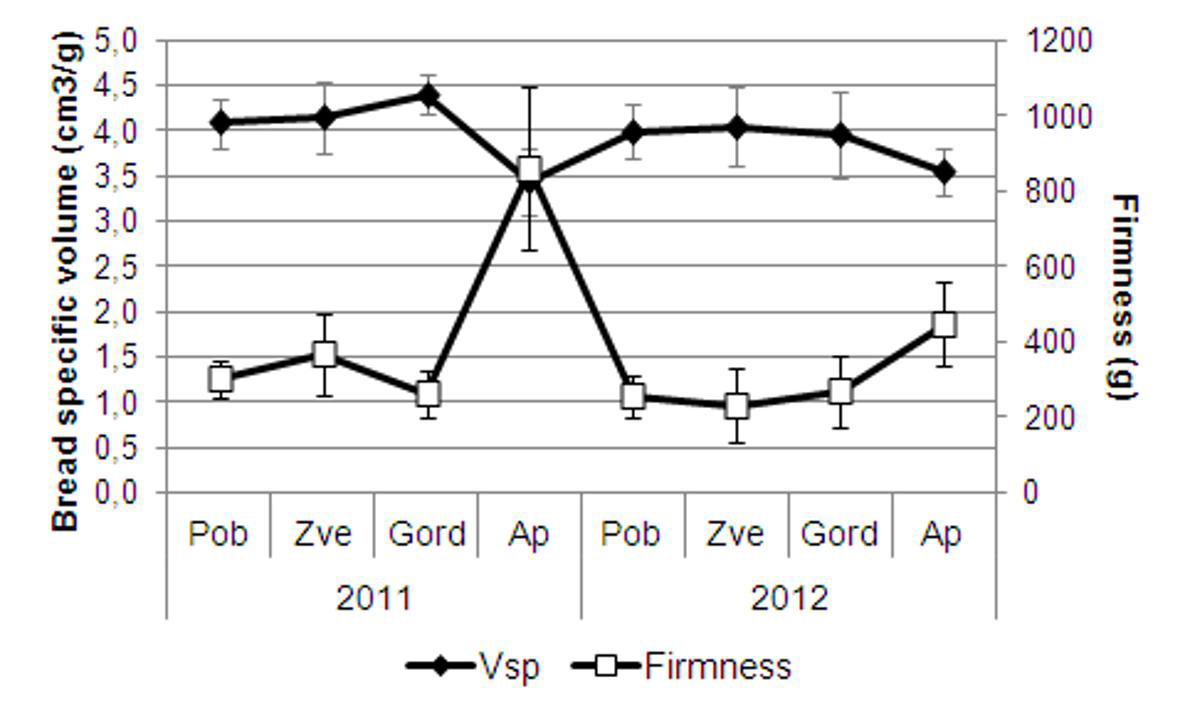

The results of bread specific volume as one of the important characteristics determining consumer acceptability (Stojčeska and Butler, 2012), showed that samples from 2012 had significantly lower values of this parameter compared to the 2011 production year (Figure 4). Variety Apache differed from other varieties having the lowest specific volume. Also, variety Apache had considerably higher values of firmness, regardless of the production year. Results of bread specific volume were consistent with the results of textural properties of bread because the bread firmness is largely influenced by its volume and crumb porosity (Liu and Scanlon, 2003; Goesaert et al. 2008). According to high PV values of samples from the 2012 production year as indication of amylolytic activity, it could be presumed that the level of amylolytic activity was under optimum which negatively affected the bread specific volume. The same presumption could be made by comparing the results of proteolytic activity and bread specific volume. The higher level of proteolytic activity could act as an effective gluten softener. This effect results in improvement of protein network flexibility, without extensive degradation of glutenins and finally the increase of bread volume (Bombara et al., 1997).

Conclusions

The results of this study have documented large variation for all of the observed wheat quality parameters. This variability was influenced by variety, location and production year. Regarding the parameters of empirical rheological methods, wheat flour samples from the 2012 production year were characterized by inferior quality parameters. Despite the markedly high level of PV values, other quality parameters indicated relatively good processing quality of all tested wheat flour samples. Proteolytic activity and bread specific volume values for the 2012 production year were significantly lower compared to those from 2011. By comparing the results of rheological methods, proteolytic activity and bread specific volume it could be concluded that the level of proteolytic activity was low to cause any quality deterioration. In fact, the obtained results implied that the level of proteolytic activity was under optimum and an increase in proteolytic activity could be beneficial for bread final quality.

АCKNOWLEDGEMENTS

This paper is a result of the research within the project TR31007 financed by the Ministry of Education, Science and Technological Development of the Republic of Serbia.