Optimization of the quantity of protein components in the high-protein instant porridge

Tamara R. Dapčević Hadnađev, Milica M. Pojić

ABSTRACT

INTRODUCTION

Lately, porridge has become a popular choice for breakfast, and it is known that breakfast is an important meal for daily appetite control. On Serbian market there are different kinds of porridges of uniform composition based on cereals, primarily oat. However, high-protein porridge products are not available to consumers in Serbia, which represent a significant deficiency in the assortment of these products. Proteins have the capacity to affect food intake and appetite in humans (Wadden et al., 1987; Graaf et al., 1992; Anderson et al., 1994) and are significant in formulating special diets based on proteins (Wadden et al., 1987). In addition, insufficient intake of quality protein remains a significant dietary problem, particularly among children and the elderly, where diets consist mainly of cereals. Results from previous studies indicated that most cereals are limited in essential amino acids such as threonine and tryptophan even though rich in lysine (Anglani, 1998; Mensa- Wilmot et al., 2001; Nnam, 2001; Perez-Consesa et al., 2002; Onweluzo and Nnamuchi, 2009), while most legumes are rich in essential amino acid particularly the sulphur containing amino acids (Radha et al., 2007; Kanu et al., 2007). Thus a combination of such food stuffs would improve the nutritional value of the resulting blend making it better compared to the individual components alone (Mensa-Wilmot et al., 2001). Development of new functional fine bakery products would have to include some raw materials based on plant proteins, such as soybean, peas and other. Although plant proteins are relatively cheap and more abundant than animal proteins, direct consumption of proteins from land plants in conventional human food is still fairly limited. Currently, most plant proteins are used as animal feed. The advantage of using plant proteins is that their sources can deliver equivalent quality of protein at lower costs and contribute to reducing greenhouse gas emissions and limiting destruction of forest land (Linnemann and Dijkstra, 2002; Dijkstra et al, 2003). In the context of human protein nutrition, the most important plant groups are cereals and legumes. Soy protein has a relatively high content of the essential amino acid lysine and is deficient in methionine, while cereal proteins have low lysine content, but are relatively rich in cysteine. The mixture of the two proteins is preferable to either one alone (Asgar, et al., 2010). The increasing popularity of using pea proteins is largely due to its low fat content and water-binding capabilities, emulsification properties and gelation, texture and nutritional values (Sandberg, 2011). One of the most important properties of pea proteins is their high content of lysine, an essential amino acid, and their deficiency in sulphur containing amino acids which makes them great compliments to other well-known cereal proteins (e.g., wheat, buckwheat) which are deficient in lysine, but have good content of sulphur amino acids (Eggum and Beame, 1983). Combining cereal and pea proteins helps to overcome the deficiencies in balance of amino acids what can markedly improve protein quality (Livingstone et al., 1993). In addition, the right combination of pulses and cereals proteins can ensure the supply of sufficient amounts of essential amino acids for human health requirements. If such high-protein porridge additionally provides energy value that satisfies requirements for one meal and is easy to prepare, then the demands of modern consumers are fulfilled. Response surface methodology (RSM) is a statistical technique that has been successfully applied in the development and optimization of cereal products (Toufeili et al., 1994; Gallagher et al., 2003; Šimurina et al., 2012). The relative contribution of predictor variables to product characteristics is evaluated that allows optimum ingredient levels to be determined (Crowley et al., 2001).

Thus, the objective of this work was to define the optimal formulation of a high-protein instant porridge containing soy protein concentrate, soy protein isolate and pea protein isolate.

MATERIALS AND METHODS

Raw materials

Ingredients used for porridge formulations were: grinded extrudate made from buckwheat and corn grits (45 g in 100 g of the main mixture) (produced at the Institute of Food Technology, Novi Sad, Serbia), oat bran (15 g in 100 g of the main mixture), sour cherry pomace (15 g in 100 g of main mixture), flax seed (10 g in 100 g of main mixture) and fructose (15 g in 100 g of main mixture). The aforementioned ingredients constituted the main mixture in which protein preparations were included. All raw materials were obtained from local supermarkets. The following protein preparations were used: soy protein concentrate (TradKon SPC HC-200, by Sojaprotein, Serbia); soy protein isolate (Olimp laboratories, Debica EU) and pea protein isolates (Nutralys F85M by Roquette, France). Characteristics of additional protein preparations according to the manufacturer's specifications are shown in Table 1.

|

Proteins preparations |

Percentage (on dry matter basis) |

|||

|

Moisture |

Protein |

Fat |

Carbohydrates* |

|

|

Soy protein concentrate |

6.0 |

70.0 |

0.5 |

23.5 |

|

Soy protein isolate |

5.2 |

92.0 |

2.0 |

1.0 |

|

Pea protein isolate |

6.0 |

90.0 |

2.5 |

1.5 |

*Calculated by difference

Soy concentrate (SC), soy isolate (SI) and pea isolate (PI) were added in amounts as shown in Table 2. The concentrations selected were established on the basis of preliminary experiments. Soy concentrate was added at lower levels because it has an unpleasant odor due to the increased content of carbohydrates and fats.

|

Independent variables |

Coded values |

|||

|

-1 |

0 |

+1 |

||

|

Real values |

Soy protein concentrate, g/100 g* |

0.0 |

7.5 |

15.0 |

|

Soy protein isolate, g/100 g* |

0.0 |

15.0 |

30.0 |

|

|

Pea protein isolate, g/100 g* |

0.0 |

15.0 |

30.0 |

|

*Main mixture (composed of buckwheat and corn extrudate, oat bran, cherry pomace, flax seed and fructose)

Chemical composition

Analysis of chemical composition of the porridges was performed according to standard A.O.A.C procedures (A.O.A.C., 2000) to determine moisture (method 926.5), crude protein (method 950.36), fat (method 935.38) and reducing sugar as invert before hydrolysis (method 975.14). Starch content was determined according to the ICC method (1994).

Water absorption capacity

Water absorption capacity of porridgewas determined by the method of Cegla et al. (1977) with little modifications. Modifications were the following: 100 g of each formulation were weighed in a 200 ml beaker. A known volume (50 ml) of water was pipetted into the beaker, carefully stirred and allowed to equilibrate for one hour at room temperature (23-25 °C). After complete water absorption, the sample was further treated with 0.1 ml water portion at 10 min interval before visual observation. The volume that gave a complete absorption of water (no visible free water) was recorded. Water absorption capacity (WAC) was calculated as the ratio of maximum amount of water in grams absorbed by 100 g dry material.

Porridge firmness

The firmness of porridges was determined using a TA.XTplus Texture Analyzer (Stable Micro Systems Ltd., Surrey, UK). The porridges were prepared with boiling water (95±1°C) at a ratio of 1:2 (w/w) by mixing for 5 minute. 50 g of porridge was weighed in a 150 ml beaker. Firmness was measured after the porridge achieved room temperature (23±1°C). An aluminum cylinder probe (SMS P/20) of 20 mm diameter was used. The penetration of probe into the product was 8.0 mm and the test speed was 2.0 mm/s with the same post-test speed. The area under the peak on the recording chart was interpreted as the work (g*sec) required for shearing the porridge and was used as a measure of firmness.

Overall acceptability evaluation

Six adults participated in the sensory test. All samples of porridges, prepared the same as for firmness test, (± 50 g) were served at 40-50 °C in plastic cups. Plastic spoons were used to evaluate the porridges. Samples were blind-coded with thee-digit random numbers. Order of serving was randomized per session; consumers within a session evaluated all simples of porridge. Consumers expressed their liking of overall acceptability using a 5-point hedonic scale: 1=dislike to 5=like very much. Water was provided at room temperature to clean the mouth between samples.

Experimental design and statistical methods

Box and Benhken design were used to investigate the effect of soy protein concentrate, soy protein isolate and pea protein isolate on the chemical composition, physical and sensory properties of the porridge (Table 3) (Box and Benhken, 1960). For some responses (protein content (PC), water absorption capacity (WAC) and porridge firmness (PF) a quadratic model was used (equation 1).

(1)

(1)

Only for overall acceptability (OA) a linear model was applied (equation 2):

(2)

(2)

Where Y is the response function of the experimental data, X1, X2 and X3 are the independent variables, and the b parameters are the estimated coefficients. The models were tested for adequacy using the ANOVA through the coefficient of determination (R2) and F-values. The significance of regression coefficients was assessed by p-values at the three significance levels (p≤ 0.01; p≤ 0.05; p≤ 0.1). Plotting responses as a function of two factors drew response surface plots, but the third factor was set to its medium value.

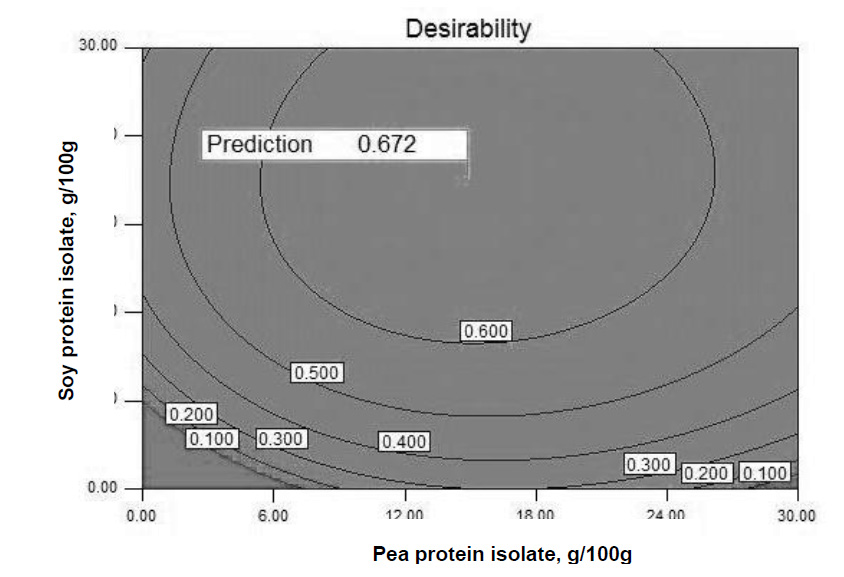

Numerical optimization was based on the desirability function (Derringer and Suich, 1980). The desirability function approach was used to assess the amount of protein preparations needed to achieve to maximum protein content and the best overall acceptability of instant high- protein porridge. Box and Benhken design and desirability function were performed with Design-Expert 8.1 (Stat-Ease Corporation, Minneapolis, MN, USA).

RESULTS AND DISCUSSION

Results of the experimental design relating to crude protein content (PC), water absorption capacity (WAC), porridge firmness (PF) and overall acceptability (OA) of the instant high-protein porridge with different concentration of soy protein concentrate (SC), soy protein isolate (SI) and pea protein isolate (PI) are shown in Table 3.

|

Run |

SC (g/100 g) |

SI (g/100 g) |

PI (g/100 g) |

PC (%/DM)* |

WAC (g/100 g) |

PF (g*sec) |

OA |

|

1 |

15.0 |

15.0 |

0.0 |

17.72 |

186.3 |

630.75 |

3.8 |

|

2 |

15.0 |

0.0 |

15.0 |

17.93 |

186.5 |

632.14 |

3.9 |

|

3 |

0.0 |

15.0 |

30.0 |

20.43 |

204.5 |

614.76 |

3.4 |

|

4 |

15.0 |

15.0 |

30.0 |

24.53 |

216.9 |

648.98 |

2.7 |

|

5 |

7.5 |

15.0 |

15.0 |

22.41 |

168.5 |

620.95 |

4.3 |

|

6 |

7.5 |

30.0 |

30.0 |

26.59 |

208.9 |

640.76 |

3.0 |

|

7 |

0.0 |

30.0 |

15.0 |

21.23 |

204.5 |

615.14 |

3.7 |

|

8 |

7.5 |

15.0 |

15.0 |

22.51 |

168.5 |

621.85 |

4.4 |

|

9 |

7.5 |

30.0 |

0.0 |

18.23 |

194.0 |

587.22 |

4.0 |

|

10 |

0.0 |

15.0 |

0.0 |

14.40 |

164.0 |

528.78 |

5.0 |

|

11 |

15.0 |

30.0 |

15.0 |

23.54 |

216.8 |

649.24 |

2.9 |

|

12 |

0.0 |

0.0 |

15.0 |

14.50 |

164.8 |

529.00 |

4.8 |

|

13 |

7.5 |

15.0 |

15.0 |

22.42 |

168.5 |

621.12 |

4.4 |

|

14 |

7.5 |

0.0 |

0.0 |

13.37 |

146.8 |

477.20 |

3.8 |

|

15 |

7.5 |

0.0 |

30.0 |

13.83 |

187.2 |

573.85 |

3.5 |

*DM – dry matter

Regression coefficients (b) for the independent factors (the applied quantity of soy protein concentrate, soy protein isolate and pea protein isolate) and their interactions are shown in Table 4. The significant terms were used to propose models for each tested response. The values of Fmodel as well as the high values of the determination coefficient (R2 > 0.85; Table 4) showed that all the models were adequate. Values of “Prob > F” less than 0.05 indicate significant model terms.

|

Coefficients |

PC (g/100 g) |

WAC (g/100 g) |

PF (g*sec) |

OA |

|

Intercept (b0) |

22.45 |

168.50 |

621.30 |

3.84 |

|

Soy protein concentrate (SC) (b1) |

1.52*** |

8.59*** |

34.18*** |

-0.45** |

|

Soy protein isolate (SI) (b2) |

3.49*** |

17.36*** |

35.02*** |

-0.30* |

|

Pea protein isolate (PI) (b3) |

2.33*** |

15.80*** |

31.80*** |

-0.50*** |

|

SC2 (b11) |

0.81 |

16.67*** |

10.57 |

|

|

SI2 (b22) |

2.33*** |

7.97*** |

-25.49** |

|

|

PI2 (b33) |

2.61*** |

7.75*** |

-26.05** |

|

|

SC x SI (b12) |

0.28*** |

2.35*** |

-17.26* |

|

|

SC x PI (b13) |

0.05 |

2.47 |

-16.94* |

|

|

SI x PI (b23) |

1.47** |

6.37*** |

-10.78 |

|

|

R2 |

0.98 |

0.99 |

0.97 |

0.68 |

|

F model |

25.78 |

115.56 |

20.82 |

7.89 |

|

F listed |

4.73 |

4.73 |

4.73 |

4.73 |

|

Prob > F |

0.0011 |

<0.0001 |

0.0019 |

0.0044 |

Statistically significant values: ***(p≤0.01); **(p≤0.05); *(p≤0.1)

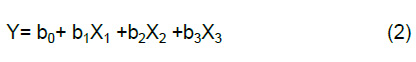

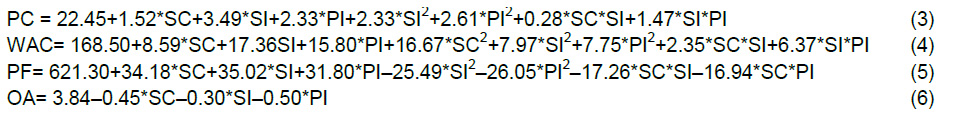

To establish predictive models for the properties of instant high protein porridge in function of varying concentrations of soy protein concentrate, soy protein isolate and pea protein isolate, the experimental data were fitted to polynomial models (described by equations 3–6). Polynomial models included only significant terms (at 90%, 95% and 99% confidence levels).

(3)

(3)

All types of applied protein preparations significantly affected the studied quality parameters of instant porridge. Appendix protein preparations significantly increased the protein content, the largest impact had the soy protein isolate, whereas the soy protein concentrate had the least impact. With quadratic increase in the quantity of protein preparations, protein content of the porridge was significantly increased, but to a lesser extent, i.e. increase was not linear. With increasing amounts of soy concentrate, the water absorption capacity increased, while with the soybean isolates, the tendency was reversed.

Soy protein concentrate was prepared by extrusion and it is known that extruded soy protein tends to increase water absorption in the mixtures (Zhu et al., 2010). In addition, soy protein concentrate contains significant amounts of carbohydrates, which also contribute to the increased absorption of water (Perez-Consesa et al., 2002). Protein isolates were commercial preparations fragmented to the level of powder granulation that increase water absorption capacity, but not in linear dependence on the added amount.

The applied protein preparations increase the porridge firmness at uniform levels, but the square increase in the amount of protein isolates reduces the porridge firmness. This is due to reduction in viscosity, which is characteristic for high-protein porridge (Pelembe et al., 2002). All protein preparations reduce the overall acceptability of porridge. The effect of pea protein preparation was the most significant in reducing the overall acceptability as compared to the soy concentrate.

Considering such negative impact of protein preparations on the overall acceptability of instant high-protein porridge, it is necessary to define their optimum concentration. In determining the optimal concentrations, the following quality parameters: protein content and overall acceptability were observed.

The criteria used for optimization along with the predicted and observed response values are presented in Table 5. The area overall desirability graph is shown in Figure 1. The predictive optimal concentrations of protein preparations were: soy protein concentrate 1.43 g/100 g main mixture, soy protein isolate 21.07 g/100 g main mixture and pea protein isolate 14.83 g/100 g main mixture. At these concentrations of the protein preparations predicted maximum protein content and maximum acceptability were 24.77 g/100g and 4.09, respectively. Again, the experiment was performed with the predicted optimal concentrations and the obtained results were close to the predicted results (Table 5). The experimental values indicated the adequacy of the developed models.

|

Factors |

Applied concentrations |

Lower limit |

Upper limit |

Optimum solutions |

|

|

Soy protein concentrate (g/100 g) |

in range |

0 |

15 |

1.43 |

|

|

Soy protein isolate (g/100 g) |

in range |

0 |

30 |

21.07 |

|

|

Pea protein isolate (g/100 g) |

in range |

0 |

30 |

14.83 |

|

|

Responses |

Goals |

Prediction values |

Experimental values |

||

|

Protein content (%/DM) |

maximize |

13.37 |

26.59 |

24.77 |

24.32 |

|

Overall acceptability |

maximize |

2.7 |

5.0 |

4.09 |

4.41 |

The nutritional characteristics of newly formulated high-protein porridge and commercially available porridge based on oats are shown in Table 6.

|

Nutritional composition |

Newly formulated high-protein porridge |

Commercial porridge |

|

Protein, %/DM |

24.32 |

10.37 |

|

Fat, %/DM |

8.62 |

9.16 |

|

*Total carbohydrates, %/DM |

54.66 |

67.12 |

|

**Energy, kJ/100 g |

1670 |

1665 |

|

***Energy from protein, kJ |

413 |

176 |

*Calculated as the sum of starch, sugar and cellulose

**Energy value from 100 g of mixture

***Energy value from protein in 100 g of mixture

The newly formulated high-protein porridge is in accordance with Serbian national regulations (Official Gazette of Republic of Serbia, 2013) and may be labeled with the statement "high-protein" because over 24% of the total energy value is provided by protein.

CONCLUSION

In this study, the influence of soy protein concentrate, soy protein isolate and pea protein isolate on the physical and chemical properties and overall acceptability of high-protein instant porridge was investigated. All three protein preparations showed a significant positive effect on the protein content, water absorption capacity and firmness of porridge, while the effect was negative on the overall acceptability. Given that the overall acceptability is important for consumers, desirability function was applied to optimize the amount of protein preparations in order to achieve maximum overall acceptability and maximum protein content. It was found that the optimal quantity for the soy protein concentrate was 1.43 g/100 g, for the soy protein isolate 21.07 g/100 g and for the pea protein isolate 14.83 g/100 g. Incorporated into the formulation, the optimized levels of protein preparations provided the high-protein instant porridge with the protein content of 24.32 %/DM and very good overall acceptability.

ACKNOWLEDGEMENTS

This paper is a result of the research within the project TR 31029 financed by the Ministry of Education, Science and Technological Development, Republic of Serbia.