Texture and stress relaxation of spelt–amaranth composite breads

ABSTRACT

This study compares the influence of different forms of amaranth (steamed and non-steamed raw amaranth flour, steamed and non-steamed popped amaranth flour and steamed whole popped amaranth grains) at two doses on quality attributes of composite spelt-amaranth breads. Besides the usual, well established, empirical parameters, fundamental mechanical properties of crumb (stress relaxation) were also assessed. Positive effects on bread characteristics (significantly increased specific volume, softer crumb) were shown by raw amaranth flour and steamed whole popped amaranth grain addition. The addition of raw amaranth flour also contributed to better crumb resilience. The results showed that stress relaxation data obtained from both Peleg-Normand and Maxwell models provided fairly good correlation with empirical quality parameters which confirms their potential to properly describe the changes in bread quality.Introduction

In recent times there has been a great interest in organically produced wheat bread. Spelt wheat is frequently used for these purposes since spelt possesses several agronomic characteristics that make it suitable for organic production. Bread made from spelt is usually inferior compared to bread made from conventional wheat and this inferiority is mainly related to lower loaf volume and impaired crumb textural properties whereas it offers similar or even better nutritional value. However, similarly to wheat, spelt amino acids are not optimally balanced for human nutrition due to deficiency in lysine. Spelt products are versatile and beside bread include pasta, ready-to-eat cereals, seedlings (Pasqualone et al., 2011), frozen bakery products (Šimurina, 2011), crackers (Filipčev et al., 2012) cookies, snacks, etc. Nevertheless, there is a permanent need to broaden the assortment of organic bakery products.

Composite bakery products may offer manifold advantages; from extended bakery assortment to improved nutritive value. The main concept of the composite flour program launched in 1964 by world health authorities was to search for non-wheat compounds which in combination with flour would give formulations offering optimal nutritive value and appropriate processing characteristics. Composite products have high potential for development of functional products and a number of alternative cereals including amaranth are in focus for development of value-added bakery products (Sedej, 2011). It was inferred by many researches the adequacy of grain amaranth in combination with wheat flour (de la Barca et al., 2010; Grobelnik Mlakar et al., 2009b; Lacko-Bartošová and Korczyk-Szabó, 2012; Sanz-Penella et al., 2013) . Upon summoning the results, it could be concluded that the most authors confirmed the supplementation levels between 10-20% as the most appropriate for composite breads. At the mentioned doses, bread quality attributes were observed to mainly deteriorate (specific volume decrease, crumb hardness increase) but to acceptable level whereas nutritional value improved significantly. However, only in few reports, spelt-amaranth mixtures were addressed. Grobelnik Mlakar et al. (2008) investigated the baking potential of composite wholemeal spelt/wholemeal amaranth flour and reported that at 10% substitution level, bread loaf volume was not negatively influenced and that texture and aroma were not impaired up to 30% substitution level. Also, it was reported that the addition of amaranth flour to common wheat, refined spelt or wholemeal spelt flour tended to stabilize dough and increase its resistance (Grobelnik Mlakar et al., 2009a). Lacko-Bartošová and Korczyk-Szabó (2012) basically confirmed the positive effect of amaranth flour addition on rheological properties of spelt dough.

Research works dealing with composite wheat-amaranth formulations mainly elaborated the addition of amaranth flour (either in the form of raw (native) or hyperproteic flour). Only several works were related to application of other forms of amaranth. Bodroža-Solarov (2008) and de la Barca et al. (2010) investigated the addition of whole popped amaranth grain to bread whereas Hernández et al. (2012) investigated combinations of raw and popped amaranth flour in processing of gluten-free bread.

The primary objective of the present study was to investigate the breadmaking potential of spelt-amaranth composite flours which encompassed versatile forms of the amaranth component (steamed and non-steamed raw amaranth flour, steamed and non-steamed popped amaranth flour and steamed whole popped amaranth grains). The breadmaking potential was evaluated by observing the most important quality aspects of bread (crumb texture and loaf volume) measuring empirical textural parameters (crumb hardness, crumb resilience) and fundamental mechanical properties of crumb (stress-relaxation). Thus, the second objective of this study was to describe the stress relaxation behavior of composite breads and to estimate its suitability to discern differences among various breads as well as to investigate the correlation between empirical and fundamental textural properties.

MATERIAL AND METHODS

Bread preparation

Spelt flour was supplied from ecological agricultural farm ²Jevtić², Bačko Gradište, Serbia. Amaranth grain was purchased from a local market. Amaranthus cruentus species was used in this study. Amaranth grain was popped on an aluminium hot plate at 200 °C for 10 s. Amaranth flour was obtained by milling whole amaranth grain on a Bühler laboratory mill (Bühler AG, Switzerland). Flour passages A and B were combined in a single sample whereas bran fractions were discarded. Popped amaranth flour was obtained by milling popped amaranth grains on a hammer mill type Lab Mill 3100 Perten (Sweden).Bread preparation was based on a basic formulation that contained (on flour basis): 100% spelt flour, 2.5% fresh compressed yeast, 2% salt, and 0.050 g/kg ascorbic acid. Water was added to achieve consistency of 400 B.U. according to farinogram. Composite spelt-amaranth breads were elaborated by substitution of spelt flour with either 10% or 20% of amaranth in various forms: steamed and non-steamed raw amaranth flour, steamed and non-steamed milled popped amaranth and steamed popped amaranth. This has yielded nine different formulations of composite breads and one control without amaranth addition.

A modified breadmaking procedure used in this study is described in detail in the work of (Filipčev et al., 2013). The duration of final fermentation time was estimated by experienced baker and varied among different bread formulations ranging between 55 and 70 min.

Bread quality tests

Volume of bread loaves was determined using a millet seed displacement method. Bread crumb firmness was determined according to the standard AACCI 74-10A method (AACCI, 2009) using a 36 mm diameter probe. Crumb resilience was determined as a percentage of recovery of sample’s height in relation to its initial height after maximal compression at 60% strain during 2 seconds followed by a recovery period of 15 s.Stress relaxation test

Stress relaxation test was conducted on a texture analyzer TA-XTplus (Stable Micro Systems, Surrey, England) equipped with a stainless steel probe 36 mm (diameter). Bread samples were compressed with the probe to a 12% strain at 1 mm/s pretest and 0.5 mm/s test speed. The loading was kept constant during 600 s. The reaction force and stress-time history was recorded during the test. The obtained stress relaxation curves were subjected to analysis using the Peleg-Normand and Maxwell models.Statistical analysis

Statistical analysis was performed using the software package Statistica 12 (StatSoft, Inc., Tulsa, OK). Fisher’s LSD test was used to differentiate means between the samples. Non-linear regression analysis (Levenberg-Marquardt method) was used to process stress relaxation data.

RESULTS AND DISCUSSION

Bread properties

Table 1 shows the major quality characteristics of breads obtained by the addition of different forms of amaranth grains at 10% and 20% dose. All observed parameters were significantly affected by type and dose of ingredients but without clear trends within the majority of different formulations. Specific volume ranged from 2.90 ml/g to 3.68 ml/g (3.47 ml/g for the control).| Spelt-amaranth bread |

Specific volume |

Hardness (g) |

Resilience (%) |

|

00 |

3.47c,d |

845.48b,c,d |

67.24c,d,e |

|

01 |

3.64e,f |

778.83a,b,c |

76.39g |

|

02 |

3.53d,e |

637.95a |

69.27d,e,f |

|

03 |

3.10b |

1120.37f |

71.83e,f,g |

|

04 |

3.10b |

1088.2e,f |

73.40f,g |

|

05 |

2.98a,b |

1098.3e,f |

66.28c,d |

|

06 |

3.48d |

705.59a,b |

56.62b |

|

07 |

3.68f |

675.94a |

68.68d,e,f |

|

08 |

3.39c,d |

906.88c,d |

55.08a,b |

|

09 |

3.33c |

945.22d,e |

62.34c |

|

10 |

2.90a |

1654.91e |

50.12a |

a,b,c,...Significant at p≤0.05 (LSD test).

Sample designation: 00-control bread; 01, 02:10/20% raw amaranth flour; 03, 04: 10/20% popped amaranth flour; 05, 06: 10/20% steamed amaranth flour; 07, 08: 10/20% steamed whole popped amaranth grains; 09, 10: 10/20% steamed popped amaranth flour

Samples containing 20% steamed popped amaranth flour, 10% and 20% popped amaranth flour and 10% steamed amaranth flour had significantly lower specific volume than the control. Only the addition of 10% raw amaranth flour or steamed whole popped grains resulted in a significantly higher specific volume. In relation to the control, significantly softest crumb was presented by samples containing 20% raw amaranth flour and 10% steamed whole popped grains whereas significantly harder crumb was observed in breads with popped flour (10, 20%), 10% steamed flour and 20% steamed popped flour. Resilience is an important quality feature of bread crumb which reflects its ability to regain its original position after deformation. Significantly higher crumb resilience relative to the control was shown in sample with 10% raw amaranth flour. Significant worsening of crumb elastic properties was found in formulations that contained 20% of any of the steamed variants of amaranth. Despite little clear trends, the results pointed out that the addition of raw amaranth flour and steamed popped whole amaranth grains positively influenced bread attributes by significantly increasing specific volume and improving the viscoelastic crumb properties. The only exception was that steamed popped whole amaranth grains at 20% dose did not contribute to better resilience but significantly lowered it in relation to the control.

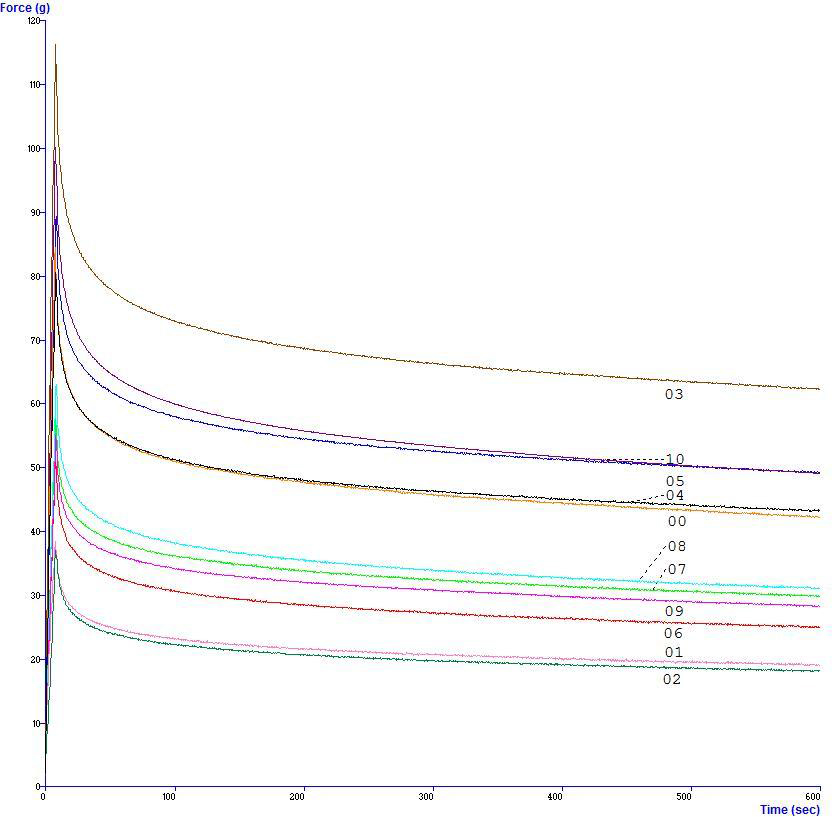

Stress relaxation

Stress relaxation of composite spelt-amaranth breads was conducted to investigate the suitability of stress relaxation parameters to characterize differences among the breads. The stress relaxation curves show the decaying behavior characteristic for most viscoelastic materials (Fig. 1). Peleg-Normand and generalized Maxwell model were used for data fitting. The obtained fitting parameters are presented in Table 2.Sample designation: 00: control bread; 01, 02: 10/20% raw amaranth flour; 03, 04: 10/20% popped amaranth flour; 05, 06: 10/20% steamed amaranth flour; 07, 08: 10/20% steamed whole popped amaranth grains; 09, 10: 10/20% steamed popped amaranth flour

The reciprocal of the k1 value in the Peleg-Normand model represents the initial rate of relaxation. High k1 values indicate low decay rate associated with pronounced elastic behavior. The k1 values in composite spelt-amaranth breads ranged from 51 to 65. So far, this constant has not been considered as a reliable parameter to discern viscoelastic properties as it is surmised to depend on numerous other factors such as sample shape, and experimental errors (Buňka et al., 2013; Peleg, 1979, 1980; Singh et al., 2006) . Even so, some authors found that this parameter was able to detect the differences among various samples e.g. among cooked spaghetti with rising content of resistant starch in the work of Sozer et al., 2008 or among cooked Asian-style noodles made from various common and durum wheat in the work of Hatcher et al. (2008) showing that k1 was highly correlated to the springiness of high-fiber steamed breads. Mandala et al. (2007) reported medium strong but significant correlation between crust moisture and k1 in wheat breads formulated with various hydrocolloids. Results obtained from our set of samples support the former statement on the inadequacy of this parameter to follow the textural changes since no significant correlation was found between k1 and any of the quality parameters of composite breads (Table 3).

Constant k2 is related to the residual stress in the material and describes the level to which stresses decay during relaxation. Thus, it indicates the solid nature of material although Singh et al. (2006) expect that, in food, k2 is a better indicator of elasticity than solidity. For composite spelt-amaranth breads, k2 spanned in the range 1.53-2.15. It was not significantly correlated to bread quality parameters but it is worth noting that there was weak negative correlation with specific volume (r=-0.42). Also, correlations of similar intensities were found between k2 and %SR and Fmax showing that k2 carries some information on both solidity and elasticity of the material. The existence of moderate, although non-significant, correlation (r=0.53) with Fe supports the statement that k2 is an indicator of residual stress and elastic nature in material.

Percentage stress relaxation (%SR) is another informative parameter extracted directly from the stress relaxation curve at an arbitrary time. It describes the extent of relaxation. As ideal elastic material never decays, %SR is 0, whereas for ideal liquid, %SR is 100%. In spelt-amaranth breads, %SR ranged from 44.88-53.53%. Similar range of %SR values (40-50%) for baked products were reported by Singh et al. (2006) %SR was significantly highly and inversely (r=-0.71) correlated to crumb resilience showing that less elastic crumb is less able to recover deformation. The results confirm that %SR has an ability to well reflect the elastic properties of bread crumb.

Fmax is an initial force needed to deform the sample at a given strain and it indicates the hardness of material. Indeed, Fmax was highly positively (r=0.85) to crumb hardness. In addition, it was inversely correlated to specific volume because larger loaves were softer.

Stress relaxation curves can be analyzed using the generalized Maxwell model. The decay forces (F1, F2 and F3) were highly positively correlated to hardness and Fmax showing that these parameters carried information on the rigidity i.e. solid nature of the sample (Table 3). It was as well strongly inversely correlated to the specific volume. Relaxation time (l1, l2, l3) in the Maxwell model measures the relaxation time of Maxwell elements. Its physical meaning is related to the time needed to stretch bonds in macromolecules during deformation. Shorter relaxation times are associated with less elastic behaviour and higher rigidity. In our set of samples, three relaxation times were characteristic: at longer time 191.62-698 s; at intermediate time 17.17-42.13 s and at short time 1.80-3.53 s. Relaxation times were strongly inter correlated showing that they carry the same type of information. Faster relaxation phase l3 was found to be significantly correlated to crumb resilience (r=0.61) whereas others showed moderate but insignificant correlation. This shows that relaxation times are upon a certain degree sensitive to elastic properties of bread crumb and harmonizes with the finding of Wu et al. (2012) who found that l was correlated to the springiness of steamed breads. Since the third term l3 represents the shortest relaxation time in the model, it seems that crumb resilience measured as a percentage of crumb height recovery after removal of load registers the short-time response of bread crumb. It has been implicated that smaller molecule structures in the dough are involved with shorter relaxation times (Hernández et al., 2012).

Spelt-amaranth bread |

Peleg-Normand model |

3-element Maxwell model |

|||||||||

|

k1 |

k2 |

%SR |

Fmax |

F1 |

F2 |

F3 |

l1 |

l2 |

l3 |

Fe |

|

|

00 |

52.49a |

1.90b,c,d |

51.12c,d |

86.23c,d |

13.92d |

13.61c |

16.81d,e,f |

208.67a |

17.38a,b |

1.94a,b,c |

42.16d |

|

01 |

53.62a,b |

1.89b |

51.70c,d |

39.18a |

7.62a |

5.79a |

8.80a,b |

698.08c |

42.13d |

3.53e |

15.80a |

|

02 |

50.91a |

1.53a |

52.68c,d |

39.01a |

6.68a |

6.32a |

7.86a |

201.21a |

17.17b |

2.11a,b,c |

18.14a,b |

|

03 |

56.87b,c |

2.10c,d |

46.31a |

116.37e,f |

20.93e |

21.23d |

23.33f |

197.00a |

18.48b |

1.97a,b,c |

75.53f |

|

04 |

61.85d,e |

2.10c,d |

46.15a |

80.60b,c,d |

12.89c,d |

11.68b,c |

12.89b,c,d |

191.62a |

18.83b |

2.23c |

43.29d |

|

05 |

65.42f |

2.15d |

44.88a |

89.63d,e,f |

13.88d |

12.30b,c |

14.17c,d |

191.82a |

17.55a,b |

2.14b,c |

49.28d,e |

|

06 |

54.27a,b |

1.86b |

52.03c,d |

52.08a,b |

9.10a,b |

8.35a,b |

9.087a,b |

196.92a |

16.60a |

1.80a |

25.05a,b,c |

|

07 |

64.67e,f |

1.99b,c,d |

51.78c,d |

57.92a,b,c |

10.11a,b,c |

8.33a,b |

10.86a,b,c |

357.01b |

26.83c |

2.69d |

28.02b,c |

|

08 |

58.98c,d |

1.89b,c,d |

51.53c,d |

63.7a,b,c,d |

11.43b,c,d |

10.13a,b,c |

11.02a,b,c |

203.94a |

16.49a |

1.88a,b |

31.00c |

|

09 |

62.14d,e,f |

1.99b |

48.99b |

55.31a,b |

9.31a,b,c |

8.32a,b |

9.03a,b |

213.62a |

16.57a |

1.82a,b |

28.27b,c |

|

10 |

51.16a |

1.81b |

53.53d |

121.88f |

21.36e |

23.17d |

20.77e,f |

197.73a |

17.28b |

1.97a,b,c |

56.67e |

a,b,c,...Significant at p≤0.05 (LSD test).

00-control bread; 01, 02:10/20% raw amaranth flour; 03, 04: 10/20% milled popped amaranth grains; 05, 06: 10/20% steamed amaranth flour; 07, 08: 10/20% steamed popped amaranth grains; 09, 10: 10/20% steamed milled popped amaranth grains

|

|

WA |

Vsp |

Hard-ness (g) |

Resili- |

k1 |

k2 |

%SR |

Fmax |

F1 |

F2 |

F3 |

l1 |

l2 |

l3 |

|

WA |

1.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vsp (ml/g) |

-0.10 |

1.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Hardness (g) |

-0.16 |

-0.89* |

1.00 |

|

|

|

|

|

|

|

|

|

|

|

|

Resilience (%) |

0.76* |

0.30 |

-0.42 |

1.00 |

|

|

|

|

|

|

|

|

|

|

|

k1 |

0.02 |

-0.14 |

-0.05 |

0.18 |

1.00 |

|

|

|

|

|

|

|

|

|

|

k2 |

0.03 |

-0.42 |

0.28 |

0.23 |

0.74* |

1.00 |

|

|

|

|

|

|

|

|

|

%SR |

-0.50 |

-0.04 |

0.05 |

-0.71 |

-0.14 |

-0.45 |

1.00 |

|

|

|

|

|

|

|

|

Fmax |

-0.09 |

-0.82* |

0.85* |

-0.24 |

-0.01 |

0.43 |

0.05 |

1.00 |

|

|

|

|

|

|

|

F1 |

-0.12 |

-0.78* |

0.84* |

-0.27 |

-0.08 |

0.38 |

0.02 |

0.99* |

1.00 |

|

|

|

|

|

|

F2 |

-0.13 |

-0.77* |

0.85* |

-0.32 |

-0.18 |

0.27 |

0.08 |

0.97* |

0.99* |

1.00 |

|

|

|

|

|

F3 |

-0.04 |

-0.68* |

0.73* |

-0.12 |

-0.14 |

0.36 |

-0.04 |

0.96* |

0.97* |

0.96* |

1.00 |

|

|

|

|

l1 |

0.06 |

0.53 |

-0.30 |

0.48 |

-0.10 |

-0.05 |

-0.51 |

-0.45 |

-0.38 |

-0.41 |

-0.33 |

1.00 |

|

|

|

l2 |

0.13 |

0.49 |

-0.28 |

0.54 |

-0.05 |

0.01 |

-0.54 |

-0.39 |

-0.33 |

-0.37 |

-0.27 |

0.99* |

1.00 |

|

|

l3 |

0.24 |

0.45 |

-0.27 |

0.61 |

0.02 |

0.02 |

-0.50 |

-0.39 |

-0.35 |

-0.39 |

-0.29 |

0.95* |

0.98* |

1.00 |

|

Fe |

0.08 |

-0.79* |

0.72* |

-0.08 |

0.08 |

0.53 |

-0.09 |

0.96* |

0.95* |

0.92* |

0.96* |

-0.46 |

-0.40 |

-0.40 |

*Significant at p≤0.05

Equilibrium stress Fe in the Maxwell model showed strong correlation to specific volume and crumb hardness. There was a moderate correlation (r=0.53) between k2 and Fe but it was not significant showing that k2 may be partly interpreted as an indicator of residual stress in the sample.

CONCLUSION

Although little clear trends could be observed in the effect of various forms of amaranth compound, positive effects on bread quality attributes were exerted by raw amaranth flour and steamed whole popped amaranth grain which increased the specific volume and softened the crumb. The only difference in the effects between these two forms was a decrease in crumb resilience for steamed popped amaranth at higher substitution level.The results showed that stress relaxation data are suitable in observing the differences among various composite spelt-amaranth breads. In the Peleg-Normand model, Fmax was strongly correlated to crumb hardness and loaf volume whereas %SR was well correlated to crumb resilience. In the generalized Maxwell model, crumb hardness and loaf volume were strongly correlated to decay and equilibrium forces. Relaxation times showed some correlation to crumb resilience.

The existеnce of strong and medium correlations between the stress relaxation parameters and bread quality attributes indicates that stress relaxation profile reflects well the mechanical properties of bread.

ACKNOWLEDGEMENT

This work is a part of research conducted within project III 46005 supported by the Ministry of Education, Science and Technological Development of the Republic of Serbia.