Changes in quality parameters of bread supplemented with OSA starch during storage

ABSTRACT

Introduction

The quality features determining the consumer choice when choosing bread are those related to its appearance such as the volume (size) of the bread, the colour - particularly that of the crust and the shape of the loaf. Moreover, when choosing bread the consumer wants to get the impression of its freshness which is often checked by squeezing a loaf. Therefore, the crust colour and texture could be considered as key determinants of consumer perception of bread quality (Sahi and Little, 2006).Although the individual consumer perceptions of bread freshness highly depends on social and demographic factors as well as product experiences, in general, freshly baked white bread is characterized by pleasant aroma and tender crumb and crunchy crust (Heenan et al., 2008). However, immediately after baking a serious of changes in all components of bread starts that affect bread quality deterioration, known as bread staling (Gellynck et al., 2009).

Staling is considered as the deterioration of sensory characteristics of bread crumb and crust rather than microbiological spoilage. This deterioration is reflected in the development of ‘stale’ flavour, dry and firm crumb and tender crust characterised with high-intesity chewiness, affecting a decrease in consumer acceptance of bread. Bread staling is a very complex process that is a consequence of several changes in the starch structure: amylopectin retrogradation, reorganisation of polymers within the amorphous region, loss of moisture content and distribution of water content between the amorphous and crystalline zone (Rosell et al., 2001).

Although bread is commonly consumed within a day when it is baked, the modern lifestyle has imposed the need for production of bread of extended freshness. In this regard, several types of additives have been developed aimed at improving the quality of fresh bread and bread staling retardation such as different enzymes (α-amylases, hemicellulases, lipases) (Palacios et al., 2004; Haros et al., 2001; Goesaert et al., 2009; Moayedallaie et al., 2010) emulsifiers (sodium/calcium stearol lactylate, mono/diglycerides) (Collar, 2003; Gomes-Ruffi et al., 2012), hydrocolloids (carboxymethylcellulose, k-carrageenan, guar gum, alginate, and xanthan) (Guarda et al., 2004; Bárcenas and Rosell, 2005) and recently modified starches (Hung and Morita, 2004; Miyazaki et al., 2004, 2005a, 2005b, 2006; Dapčević Hadnađev et. al., 2013a; Dapčević Hadnađev et. al., 2013b).

Since it was previously noted that octenyl succinate starches (OSA modified starches) can be used as bread improvers, due to their ability to reduce bread crumb firmness and thus give the impression of prolonged bread freshness (Dapčević Hadnađev et. al., 2013a; Dapčević Hadnađev et. al., 2013b), the aim of this study was to investigate the relationship between bread crumb colour alteration and crumb moisture and firmness changes over a pre-defined period of storage. Therefore, the ability of colour quality characteristics to be used for monitoring of bread stalling as cheaper and less time consuming method as a potential alternative to differential scanning calorimetry, X-ray diffraction, enzymatic tests, panel evaluation and/or crumb texture analysis was tested.

MATERIAL AND METHODS

Commercial wheat flour (12.9% moisture content, 11.9% protein db, 0.64% ash db) was provided by Fidelinka Milling Company AD (Serbia). Three types of modified starches with emulsifying properties belonging to the group of starch sodium octenyl succinates starches were used as additives in these experiments: starch sodium octenyl succinate (C*EmTex 06328, Cargill, France) – Starch 1, pre-gelatinized starch sodium octenyl succinate (C*EmTex 12688, Cargill) – Starch 2 and hydrolyzed and spray-dried starch sodium octenyl succinate (C*EmCap 12633, Cargill) – Starch 3. Salt and yeast were purchased from the local market.Breadmaking Process

The bread formula which was based on flour weight (14% mb) was prepared using wheat flour or wheat flour with the addition of 5% of the starch sodium octenyl succinates, water up to 500-BU consistency, 2.5% fresh yeast and 2% salt. Dough samples were prepared by mixing 300 g of wheat flour or wheat flour/modified starch mixtures, salt and compressed yeast in a 300-g Farinograph bowl until dough reached the maximum consistency and was additionally mixed for 1 min. The fermentation and baking tests were performed according to procedure which was given by Dapčević Hadnađev et al. (2013a). After baking, bread loaves were cooled at room temperature for 2 h and subsequently sealed in polyethylene bags.

Colour measurements

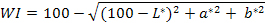

After mixing, a part of the dough was taken for colour measurements in order to monitor the influence of modified starch addition on dough colour. Colour measurements were carried out in five replicates using a Minolta Chroma Meter CR-400 colorimeter (8 mmØ contact area; Konica Minolta Sensing Inc., Japan). The instrument was calibrated against a standard light white reference tile and the measurements conducted under standard illuminant D65. The obtained results were expressed in Commission Internationale d’ Eclairage L* (lightness, L*=0, black; L*=100, white), a* (redness-greenness), b* (yellowness-blueness) colour-space (Jambrec et al., 2011).Whiteness index (WI) was calculated using obtained L*, a* and b* values to describe the, as follows:

Bread quality evaluation

Evaluation of selected quality parameters during storage was performed 2 h, 24 h and 72 h after baking. Bread crumb moisture content was determined according to ICC 110/1 (ICC, 2008) in three replicates.

Bread crumb colour measurements were performed in five replicates per loaf using the same procedure as for dough colour measurements.

Changes in textural characteristics of bread crumb samples were monitored by texture profile analysis (TPA) at room temperature using a TA XT2 Texture Analyser (Stable Micro Systems, UK) equipped with a 30-kg load cell and a P/75 (75-mm diameter) aluminium compression platen. Bread crumb samples (35 mm in diameter, 10 mm thick) were gently cut out from the centre of loaf slice. Five loaf slices were cut from each bread. TPA test settings were: pretest, 1 mm/s; test and post-test speed, 5 mm/s; deformation, 75%; and wait time between first and second compression cycles, 5 s. Firmness parameter, as one of the most important parameter in the texture profile analysis, was monitored over the tested storage period.

Data analysis

All measurements were conducted in replicates and the obtained results were reported as mean values with the standard deviations. The analysis of variance (ANOVA) and Tukey’s multiple range tests were performed using Statistica 10.0 (Statsoft, Tulsa, OK). All statistical analyses were conducted at a significance level of P < 0.05.Results and Discussion

The effect of OSA starch addition on dough colour parameters is shown in Table 1.

Sample |

L* |

a* |

b* |

WI |

|

Control |

76.29±0.32a |

0.70±0.06a |

17.41±0.26a |

70.57±0.41a |

|

5% Starch 1 |

77.52±0.22b |

0.81±0.09a |

16.57±0.19b |

72.06±0.28b |

|

5% Starch 2 |

77.39±0.27b |

0.28±0.12b |

14.49±0.57c |

73.20±0.59c |

|

5% Starch 3 |

75.95±0.44a |

1.14±0.11c |

15.54±0.13d |

71.33±0.41d |

(a)Mean value ± standard deviation of three replicates; values followed by the same letter in the column are not significantly different (p>0.05)

The addition of emulsified starches in wheat flour dough resulted in increased lightness (L*) and decreased yellowness (b*) values. The increased whiteness index (WI) of dough containing OSA starches could be attributed to the fact that used starches diluted the pigments which can be found in wheat flour. The similar finding was noted by Baixauli et al. (2008) who revealed that incorporation of resistant starch resulted in the increase in "white" colour of muffins.

According to Lukow et al. (2009), the yellow colour (b*) in bread crumb significantly correlates to the carotenoids content in grain and flour. Therefore, bread doughs in which carotenoids content was diluted with addition of OSA starch resulted in bread crumbs which were whiter, lighter and less yellow (Table 2).

|

2 h |

24 h |

72 h |

|

|

L* |

|||

|

Control |

62.48±0.86a,1 |

68.14±0.10a,2 |

73.17±0.64ab,3 |

|

5% Starch 1 |

66.43±1.16b,1 |

70.77±0.53b,2 |

73.99±0.74a,3 |

|

5% Starch 2 |

65.29±2.08bc,1 |

67.95±1.82a,2 |

71.99±0.43bc,3 |

|

5% Starch 3 |

64.70±1.37c,1 |

69.06±0.89a,2 |

74.23±0.45a,3 |

|

a* |

|||

|

Control |

1.11±0.07ab,1 |

1.22±0.09ab,12 |

1.17±0.10ab,12 |

|

5% Starch 1 |

1.13±0.07a,1 |

1.02±0.13bc,12 |

1.00±0.05bc,12 |

|

5% Starch 2 |

1.00±0.06ab,12 |

0.90±0.14c,1 |

1.05±0.12bc,12 |

|

5% Starch 3 |

1.14±0.13a,1 |

1.38±0.08a,2 |

1.14±0.11b,1 |

|

b* |

|||

|

Control |

19.82±0.26a,12 |

19.93±0.29a,1 |

19.09±0.57a,3 |

|

5% Starch 1 |

19.51±0.20a,1 |

18.90±0.16b,12 |

18.34±0.33ab,12 |

|

5% Starch 2 |

18.06±0.18b,1 |

17.67±0.62c,1 |

17.60±0.21bc,1 |

|

5% Starch 3 |

18.88±0.21c,1 |

19.24±0.61ab,2 |

17.55±0.11c,3 |

|

WI |

|||

|

Control |

57.55±0.72a,1 |

62.40±0.16a,2 |

67.00±0.82a,3 |

|

5% Starch 1 |

61.15±1.07bc,1 |

65.14±0.43b,2 |

68.15±0.77ab,3 |

|

5% Starch 2 |

60.85±1.87bc,1 |

63.99±1.79bc,2 |

66.90±0.46a,3 |

|

5% Starch 3 |

60.09±1.30b,1 |

63.54±0.80ac,2 |

68.80±0.38ab,3 |

(a,1)Mean value ± standard deviation; values followed by the same letter in the column or number in the row are not significantly different (p>0.05)

During storage bread crumb lightness (L*) and whiteness (WI) increased, while yellowness (b*) decreased. It was in accordance with the results obtained by Pasqualone et al. (2007), Dodić et al. (2007), Popov-Raljić et al. (2009), Pająk et al. (2012) and Charoenthaikij et al. (2010). Addition of OSA starches reduced the rate of lightness increase, since the relative increase in lightness after 72 h of bread storage, in comparison to the initial lightness, was 17.1, 11.4, 10.3 and 14.7% for control, Starch 1, Starch 2 and Starch 3, respectively.

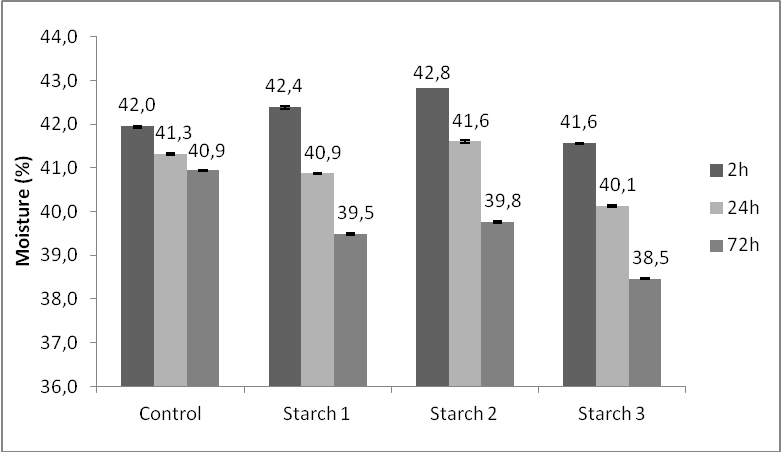

There are a few possible explanations for the increased lightness (L*) and whiteness (WI) of bread crumb during storage. Firstly, the progressive loss of moisture content due to its migration from crumb to crust resulted in the increase in opacity (Pasqualone et al., 2007). Changes in the moisture content, presented in Figure 1 revealed that bread storage resulted in progressive loss in crumb humidity.

Moreover, the addition of Starch 1 and 2 resulted in bread crumbs with initially higher content of moisture in comparison to the control bread, which was in accordance to the fact that these two starches gave lighter bread crumbs. However, all the tested OSA starches did not exhibited water retention capacity since the relative moisture loss after 72 h of bread storage was 2.5, 6.9, 7.2 and 7.5% for control, Starch 1, Starch 2 and Starch 3, respectively. Therefore, the increase in lightness during storage could not be correlated only to changes in moisture content.

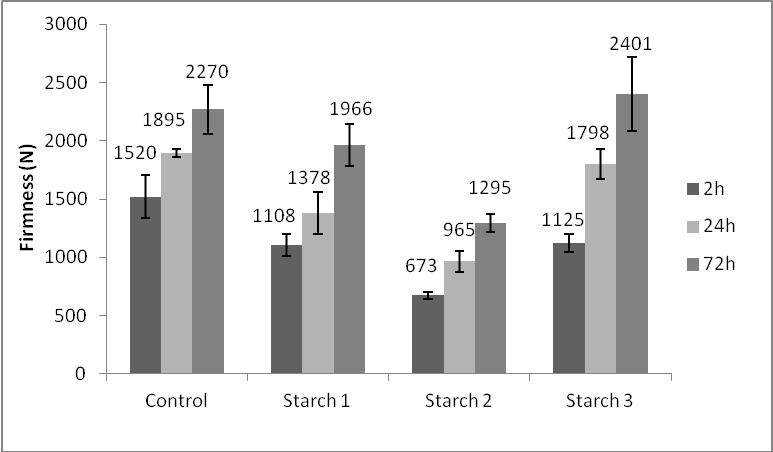

The changes in crumb structure also led to the changes in mechanical properties of crumb, which could be observed from the results of firmness measurements presented in Figure 2. During prolonged storage the bread crumb firmness increased as a consequence of starch retrogradation and water loss (Biliaderis et al., 1995) which led to lighter bread crumbs. However, the addition of Starch 1 and Starch 2 resulted in bread characterized with more tender crumb texture. Firmness value of the sample with Starch 2 after 72 h of storage was still lower than that of control sample 2h after baking.

Moreover, it is well known that carotenoids are prone to oxidation (Rodriguez-Amaya, 1999) which occurs during storage and therefore prolonged storage results in decrease in carotenoids content and thus increase in crumb whiteness.

Conclusions

It was shown that bread colour characteristics monitoring can be used as an ease auxiliary method for detecting the progress of bread stalling, since during storage bread crumb lightness and whiteness increased and yellowness decreased. The increase in crumb lightness was the consequence of joint phenomena such as water loss, crumb shrinkage, and flour pigments oxidation. Addition of OSA starches diluted flour pigments and led to lighter bread crumbs, especially those supplemented with starch sodium octenyl succinate and pre-gelatinized starch sodium octenyl succinate, which were also softer and characterized with higher initial moisture content in comparison to control.АCKNOWLEDGEMENTS

This paper is a result of the research within the project TR31007 (2011-2014) supported by the Ministry of Education, Science and Technological Development, Republic of Serbia.