Effect of specific packaging conditions on myoglobin and meat color

ABSTRACT

Meat and meat products are very sensitive to external factors and are very sensitive substrate for bio-chemical processes which occur during the storage. The main causes of meat quality changes are microbiological breakdown, fat oxidation and discoloration. Any discoloration has negative impact on customer choice. Color change is meat sensory attribute and directly depends on the myoglobin state. Proper packaging and packaging conditions allow protection against external influences, as well as keep sensorial, nutritional and microbiological properties to the stated expiration date. Colour is one of the most important quality characteristic of fresh meat.This paper deals with the review of literature in terms of preserving desired meat color by appropriate specific packaging requirements. Studies have shown that varying the amount of oxygen present in the packaging atmosphere can prevent undesirable oxidation and discoloration of meat. Many authors proved that increase in oxygen level is useful for color stability but oxygen promotes many deteriorative reactions (fat oxidation, microbiology failure…). Although it maintains redness during storage, rancidity often develops while color is still desirable. Therefore, oxygen level should be balanced to satisfy colour and quality needs and its values vary within wide range limits. In addition to improve performance of commercial packaging in modified atmosphere, carbon monoxide is added to the package because of its high affinity to myoglobin and its ability to form desirable color on the surface of fresh meat.Introduction

Microbial growth, color and lipid oxidation are factors important to shelf life and consequently to consumer acceptance of fresh meat (Zhao et al., 1994). Research has shown that the three sensory properties by which consumers most readily judge meat quality are appearance, flavour and texture. Among all sensory attributes of meat, color is considered one of the most important physical traits because once color is deemed unacceptable, all other sensory attributes lose their significance to consumers (Bekhit et al., 2005; Mancicni and Hunt, 2005) (McKenna et al., 2005).

Meat color depends on pigment content, oxydative impacts on pigments, pigment reactions with gass compounds, so as structure meat protein properties. Post mortem meat color changes as a consequence of myoglobin (Mb) chemical state changes and postmortal processes, regarding changes in muscles. Mb (Trout, 2003) since Mb is the primary pigment associated with meat color. In fresh meat Mb occurs in several forms: the most important is deoximioglobin (DMb), oximyoglobin (OMb) and metmyoglobin (MMb). The oxygenated form of Mb (OMb) is responsible for the bright-red color while the oxidised form (MMb) is responsible for browning (Bekhit et al., 2001).

DMb is the form of Mb in which ferrous iron (Fe2+) has no related ligands. In this case, flesh color is purple-red (purple-pink) and this is the color of fresh meat immediately after cutting. This color is synonymous with freshness and consumers consider it attractive (Renerre, 1990). Oxygenation of Mb begins when it is exposed to the influence of O2. In this case there is no change in iron valence (Fe2+) in heme. The sixth coordination relationship has diatomic O2 molecule bounded, and the flesh color is bright red. With prolonging O2 action, OMb penetrates deeply into the structure of the meat. The depth of O2 penetration and OMb thickness depends on the meat temperature, O2 partial pressure, pH and need for O2 in other respiratory processes (Mancini and Hunt, 2005).

Discoloration is the result of oxidation Fe2+ iron in to the Fe3+ iron and MMb formation, when meat becomes gray-red (brown). MMb formation depends on numerous factors, including the partial pressure of oxygen, temperature, pH, meat reduction activity and in some cases the presence and growth of microorganisms (Mancini and Hunt, 2005; Bekhit et al., 2007). Table 1 presents the most important factors affecting the meat color.

|

Temperature |

Partial O2 pressure |

pH

|

|||

|

High |

Low |

High |

Low |

High |

Low |

|

favore higher O2 con-sumption by residual respiratory enzymes, as well as other pro-cesses that consume O2 |

facilitate increased penetration of O2 |

favors the OMb formation |

favors the MMb formation |

accelerates the meat respirator activity resulting in a thin layer of OMb below which Mb is present |

cause denaturation of globin followed by dissociation of O2 from the heme |

|

promotes the dissociation of O2 from OMb, with increasing tendency of autoxidation of created Mb |

increases solubility of O2 in the fluid tis-sue |

muscle fibers swell with decreasing diffusion of O2 and thus form OMb |

promotes Mb oxidation |

||

|

each of the factors favor deeper OMb penetration |

|||||

At each partial pressure of O2 in the atmosphere oxidation of DMb to MMb begins, but in the interior and on the surface in the presence of respiration enzyme, endogenous reductive system and NADH reserves continuously reaction of MMb in Mb takes place, so long as there are agents or at high partial pressure of O2 on the surface of muscle predominates OMb (Rede and Petrović, 1997). MMb reduction is crucial for the sustainability and stability of the color post motrem. The color of the meat can be controlled by changing the composition of the atmosphere in the packaging and applying adequate highly barrier films (Šuput et al., 2012), thus improving the attractiveness of the product. Because of this fact, modified atmosphere packaging (MAP) has been popular technique for the past 30 years (McMillin, 2008). A lot of studies have been carried out in order to study the effectiveness of vacuum, different gas composition and packaging material on the preservation of fresh meat (Sorheim et al., 1999; Buys et al., 2000; Houben et al., 2000).

Structure, reactions and myoglobin function

Mb is the major protein of sarcoplasma, belongs to the group of albumin. This protein is the main pigment of muscle tissues. Muscle colors red, and its function is reversibly binding O2 which means that Mb serves as a depot for the O2 metabolism of muscle fibers (Livingston and Brown, 1981) and is functionally connected to hemoglobin. Mb content ranges from 0.02 to 0.46%. Mb is a chromoproteid composed of globin chain and prosthetic heme group. Globin may be native or denatured; iron atom can be in different oxidation states, and the porphyrin ring may be intact, oxidized, polymerized or open (Table 2). Mb activity is related to its biological functions - storage of O2 necessary living tissues - and necessary chemistry to optimize these functions. Storage of O2 depends on the heme ability to undergo oxidation-reduction reactions and electron transfer reactions (Brewer et al., 2001).

|

Pigment |

Type of bonding |

State of globin |

State of iron |

State of heme |

Color |

|

Deoxymyoglobin [DMb] |

Ionic |

Native |

Fe++ |

Intact |

Purple-red |

|

Oxymyoglobin [OMb] |

Covalent |

Native |

Fe++ |

Intact |

Bright red |

|

Metmyoglobin [MMb] |

Ionic |

Native |

Fe+++ |

Intact |

Brown |

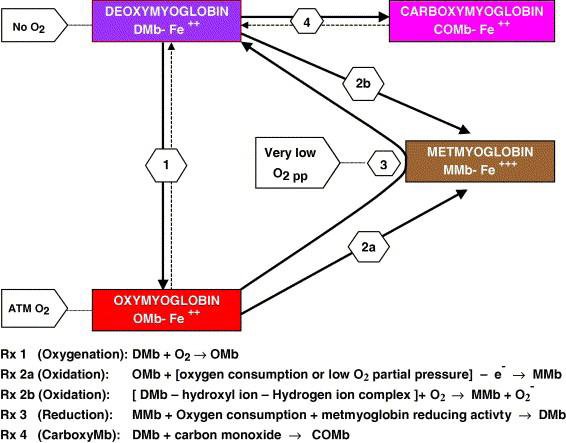

The traditional "meat color triangle" is well established in the literature, and the interconversions between deoxy-, oxy-, and met-myoglobin have been extensively studied (Figure 1). A bright pink (red) color is related to OMb, while the color of Mb and MMb is more greyish or brownish pink (red). The state of the muscle proteins affects the opacity and translucency of the meat (Lindahl et al., 2001).

Many factors affect OMb oxidation: temperature, pH, MMb reducing activity, partial O2 pressure and lipid oxidation (Faustman and Cassens, 1990). OMb oxidation is favored by higher temperatures (Brown and Mebine, 1969), lower pH values (Lindahl et al., 2001) and the presence of non-heme iron (Allen and Cornforth, 2006). MMb reducing activity can be enzymically or non-enzymically based and favors maintenance of ferrous forms of Mb in meat (Bekhit et al., 2005). Partial O2 pressure favors ferrous Mb forms. Lipid oxidation, which is unwanted and depends on meat tissue composition (Čolović et al., 2012), appears to enhance OMb oxidation. Greater concentrations of iron and Mb are associated with greater rates of lipid oxidation (Faustman et al., 2010).

Vacuum and MAP impact on meat color

Vacuum packing means drawing air, especially O2 from the package. This creates a particular microbial environment inside the package, which increases CO2, lowers pH and maintains product freshness. Prime beef cuts held at 1 oC in vacuum, can be stored for up to 10 weeks (Radetić et al., 2007).

On the other hand, MAP is a type of packaging that implies complete air removal, after which the vacuum is filled with gas or mixture of gases. Gas phase in the package is subjected to constant changes, due to absorption of gas by the product, biochemical changes that occur in the product and due to partial gas permeation through the foil for packaging (Babić et al., 2009). Three main gases used in MAP are CO2, O2 and N2. The choice of gas is very dependent upon the food product being packed. Used singly or in combination, these gases are commonly used to balance safe shelf-life extension with optimal organoleptic properties of the food (Sandhya, 2010). In addition to CO2, by dissolving in the aqueous phase of meat, builds carbonic acid which lowers the pH of meat and has a proven antimicrobial effect (Radetić et al., 2007), CO2 is very efficient for the preservation of red meat color, as it has 20 times higher affinity for binding with Mb, compared to O2`s ability (Boeckman, 2006). O 2 promotes several types of deteriorative reactions in foods including fat oxidation, browning reactions and pigment oxidation. Most of the common spoilage bacteria and fungi require O2 for growth. Therefore, to increase shelf life of foods the pack atmosphere should contain a low concentration of residual O2 (Sandhya, 2010). Nitrogen slows the development of rancidity and inhibits the growth of aerobic microorganisms in a way that replaces the O2 in the packaging (Church, 1998). It was found that the extension of shelf life of meat samples depended on the packaging conditions and augmented in the order: air < vacuum pack < 40%CO2/30%N2/30% O2 < 80%CO2/20% air < 100%CO2 (Skandamis and Nychas, 2002).

The MMb formation begins after the vacuum packaging of meat, but after a few hours MMb is reduced to Mb. The red color of meat packed in vacuum is not considered to be unfavorable, because O2 becomes available at the surface after opening of the package and it returns the preferred red meat color. However, the brown color may be due to the formation of MMb during storage, indicating the presence of O2 passed into the package or during subsequent storage (Narasimha and Sachindra, 2002). Studies showed that initial reduction of O2 in the atmosphere to a very low concentration and prevention of the entry of O2 during storage by use of a gas-impermeable film did not lead to oxydation (Narasimha and Sachindra, 2002). Investigations with pork showed that residual O2 amounts in CO2 atmosphere (1.0%) helped to avoid color defects (Penney and Bell, 1993).

Jakobsen and Bertelsen (2000) proved that increase in O2 level is useful for color stability. They packed beef stakes. O2 content in packaging varied between 20% and 80%. O2 level increment higher than 55% secures additional benefits. Color and TBARS were modeled. On the other hand, they reported that while O2 levels higher than 20% were necessary to promote meat color, package O2 contents higher than 55% did not result in additional color stabilizing benefits. Ultra-low-oxygen atmospheres minimize lipid oxidation and aerobic microorganism growth; however, muscle reducing capacity coupled with poor blooming (DMb oxygenation) after long storage can be major drawbacks to this system if ultra-low levels of residual O2 are not maintained. O2level needs to be less than 1% for pork and less than 0.05% for beef.

High-oxygen atmospheres (80% O2) promote pigment oxygenation, and therefore, prolong the time before MMb is visible on the muscle surface. The drawback to high-oxygen MAP is, although it maintains redness during storage, rancidity often develops while color is still desirable (Jayasingh et al., 2002). The quality of packaged ground beef was investigated in MAP with high O2 content (80% O2, 20% CO2) and compared with respect to the control samples stored in oxygen-impermeable containers. The high content of O2 could contribute to color stability, but also it could reduce the stability of smell and taste. Undesirable odors and flavors can be developed even before the color gets worse. MAP with high O 2 content is effective in maintaining the desired red color for 10 days in refrigerated storage (Jayasingh et al., 2002).

In order to eliminate the disadvantages of commercial ultra-low-oxygen MAP packaging, carbon monoxide (CO) is added to the package (Table 3). The US Food and Drug Administration (FDA) approved CO as a substance that is ''Generally Recognized as Safe'' (GRAS) for levels up to 0.4% in MAP systems (FDA, 2001). It is highly improbable that the use of CO in the packaging of meat will present a toxic threat to consumers (Sorheim et al., 1997; Mastilović et al., 2010).CO has high affinity for Mb and ability to form a light-pink color on the surface of beef (Hunt et al., 2004; Jayasingh et al., 2001) and pork (Krause et al., 2003). CO has been very effective in maintaining the red colour in fresh meat due to the formation of carboxymyoglobin (MbCO) (Fontes et al., 2004). The bright red pigment MbCO is more stable towards oxidation than OMb, due to the stronger association of CO to the Mb molecule. MbCO is less likely to oxidize to the brown pigment, MMb, during display. Most CO MAP atmospheres contain no O2 which limits oxidation and growth of aerobic microorganisms. Addition of CO at low levels counteracts undesirable colour changes associated with high levels of CO2 (Luno et al., 2000). CO acts to Mb 20 times more intensive than O2 and 240 times more intensive to the hemoglobin. Therefore, only small concentration of CO is necessary so the meat has cherry red color (Klettner, 2004). The shelf-life of pork chops was extended to more than 36 days in CO-MAP compared with only 28 days in traditional, high oxygen MAP, 23 days in vacuum packaging and 7 days for overwrapped packages (Krause et al., 2003).

|

Gas combinations (%) |

||||

|

CO |

CO2 |

N2 |

O2 |

air |

|

2 |

98 |

|||

|

1 |

50 |

49 |

||

|

0.5-10 |

90-99.5 |

|||

|

1 |

51 |

18 |

30 |

|

|

1 |

50 |

25 |

24 |

|

|

1 |

20 |

9 |

70 |

|

|

2 |

20 |

78 |

||

|

1-5 |

95-99 |

|||

|

100* |

||||

|

0.4 |

60 |

40 |

||

|

0.3-0.4 |

60-70 |

30-40 |

||

*(exposure before packing)

Krause et al. (2003) packed pork chops in four different atmospheres (aerobic, vacuum, MAP without CO and MAP with CO). The experiment lasted for 36 days on the fridge temperature. 0.5% CO applied in MAP can improve the color stability of pork chops over a long period of storage. The depth of penetration of CO on the surface increases as the exposure time increases. Similar experiment was carried out by Wicklund et al. (2006) who packed pork chops in atmosphere: CO-MAP and HiOx-MAP. Chops packaged in CO-MAP were redder (higher a* values) and darker (lower b* values) which would make them more appealing to consumers.

Another experiment was undertaken to evaluate the microbiological, color and sensory attributes of pork loins packaged with different gas mixtures: vacuum, 100%CO2, 99%CO2+1%CO, 100%O2 or 100%CO followed by vacuum and stored at 4 °C. The 1% CO/99%CO2 atmosphere was best for preserving the desirable pork loin color and the L* and a* values remained similar to the fresh meat values using this MAP. Pork loins in 99% CO2/1% CO MAP obtained the highest consumer acceptance scores after 24 h of storage. These samples and those treated with CO and then vacuum packaged received the greatest acceptance scores even after 20 days of storage (Viana et al., 2005).

Inclusion of CO at 0.4% in the gas mixture provided a clear advantage over 100% CO2 for the maintenance of a bright, pink-red fresh pork colour under MAP conditions. The inclusion of CO in the master-packaging environment did not influence the growth of spoilage bacteria and pathogenic organisms were not inhibited under 0.4% CO conditions. MAP with 0.4% CO is recommended for extended storage of fresh pork in a master-pack arrangement such that export to distance markets can be accommodated (Wilkinson et a., 2006). Same results were obtained by Hunt et al. (2004). Biochemical profile of muscle can affect by its response to CO.

Jayasingh et al. (2001) reported that packaging steaks and ground beef in 5% CO improved color stability. The goal of their work was to achieve more than 21 days of stable color beef steaks treated with CO prior to vacuum packaging. Pretreatment with 5% CO can improve color stability during storage in vacuum packaging. The use of 5% CO in MAP system also improves the stability of the steak color. It is anticipated that the steak color may take longer than 3 weeks in vacuum packaging if the duration of pre-treatment with 5% CO extend to more than 24 h. Pretreatment with 5% CO followed by VP would allow for central packaging and distribution of VP beef steaks and retention of desirable red color for > 21 days, which is considerably longer than the average color stability of 3-10 days for beef in PVC film.

Whereas Hunt et al. (2004) and Jayasingh et al. (2001) combined O2 exclusion and low levels of CO, Luno et al. (2000) tested a CO packaging system that also contained 24% O2. Atmosphere with low CO concentrations (0.1 to 1%) is applied, in combination with O2 (24%), CO 2 (50%) and N2 (25 to 25.9%), for the refrigerated beef cuts maintenance. Combining 0.5, 0.75 or 1.0% CO with 24% O2 can stabilize beef color. The lower levels of CO are less effective in the presence of 24% O2. But even the gas mixture containing only 0.1% CO enhanced and stabilized the color and fragrance in the early stages of storage. It has been shown that the atmosphere containing 50% CO2 and 0.5 to 0.75% CO in the presence of 24% O2 was able to extend the shelf life of fresh beef steaks from 5 to 10 days, at 1.1 °C, compared with storage in the atmosphere 70% O2 + 20% CO2. Higher levels than 0.5% of CO may increase the risk of masking spoilage with desirable color; however, the off-odors of spoilage should be present.

Similar experiment was carried out by John et al. (2004) on samples packed in an oxygen-rich atmosphere. The conclusion was that beef had less desirable color compared to beef packaged in MAP with CO or vacuum. Raw ground beef packaged in 0.4% CO-modified atmosphere, retained desirable color during the storage period of 21 days and premature browning was avoided. MAP with high O2 content increases, while low O2 content and 0.4% CO prevents premature browning of ground beef.

Conclusions

Food quality is the sum of three principal components: nutritional value, safety and consumer acceptability. During food preservation and preparation for the market it is necessary to take into account the conditions where food is exposed. Consumer acceptability includes a large array of attributes such as visual appeal, aroma, flavor, texture, mouth feel, convenience and cultural relevance. The color of meat and meat products is an important aspect of consumer acceptability and it influences the purchase decision by consumers. Meat purchasing decisions are influenced by color more than any other quality factor because consumers use discoloration as an indicator of freshness and wholesomeness. Meat color depends on the amount and the state of Mb in meat. The oxygenated form of Mb (OMb) is responsible for the bright-red color while the oxidised form (MMb) is responsible for browning. Among the packaging technologies developed by and for the food industry, MAP has led the evolution of fresh and minimally processed food preservation, specially in meat and meat products. Shelf-life prolongation could be achieved by combining different gas mixtures for MAP packaging of fresh meat while quality stays maintained to the stated expiration date. The application of MAP to processed meat has grown greatly in recent years, but optimisation of gas composition is critical to ensure both product quality and safety. The presence of O2 is very important in the storage of fresh meats as it maintains the meat pigment myoglobin in its oxygenated form, oxymyoglobin, which gives fresh meat its bright red colour. However, high O2 was not desirable in the gas mixtures for long term storage of pork because O2 supports the growth of aerobic microorganisms; thus, O2 removal will extend the microbiological shelf life. Although a substantial increase in the shelf life of meat can be obtained by using various MAPs: it is often limited by discolouration due to the oxidation of myoglobin to metmyoglobin. This discolouration can be prevented by the inclusion of a low level of CO in the gas mixture. Carboxymyoglobin is more resistant to oxidation than oxymyoglobin, owing to the stronger binding of CO to the iron-porphyrin site on the myoglobin molecule so the main function of low levels of CO in MAs is to give meat a stable, cherry red colour, as a result of strong binding of CO to myoglobin and the formation of carboxymyoglobin.

ACKNOWLEDGEMENTS

This work is part of project TR 31055 („Osmotic dehydration of food - energy and environmental aspects of sustainable production") financed by Ministry of Education and Science Republic of Serbia and project 2618/2012 („Improving the quality of meat and native pig breeds reared in Vojvodina for the production of traditional fermented dry sausages and meat products") financed by Provincial Secretariat for Science and Technological Development.