Chicken meat added bread formulation for protein enrichment

ABSTRACT

Introduction

Wheat and wheat products are the major staple foodstuffs in the human diet. They are source of calories and contribute significant quantities of other nutrients such as vitamins, minerals, and dietary fibre (Sidhu et al., 1999). Bread and other wheat products are one of the most consumed foods in the daily diet of all people around the world, although the level of consumption varies from region to region (Cauvain, 1995). According to the research of the Turkish Society of Cardiology (Istanbul, Turkey), 37% of the daily energy intake of the Turkish people is fulfilled by cereals and other related products while meat and poultry products fulfill only 6% (Aslan et al., 2006). Since fortification of white flour and white bread with thiamine and riboflavin is not a new subject (Pyler, 1973), wheat flour should be considered as a good source for enrichment and fortification as it is regularly consumed by large populations (WHO et al., 2009). To define the terms; fortification is described as increasing the content of essential micronutrients, i.e. vitamins and minerals, including trace elements, in a food so as to improve the nutritional quality of the food supply and provide a public health benefit with minimal risk to health, while enrichment is the addition of micronutrients to a food irrespective of whether the nutrients were originally in the food before processing or not. To deal with malnutrition problems, some strategies were developed at the International Conference on Nutrition with a consensus by 159 countries worldwide about the enrichment of foods (Allen et al., 2006). Since wheat products are the main item of a daily diet, enrichment techniques are mostly studied on this food.

Various alternatives for enrichment of bread have been discussed in literature. Oliete et al. (2008) are enriched breads with nut pastes to determine the morphogeometric and textural characteristics along with the consumer acceptability of the breads. Conforti and Cachaper (2009) have studied the flaxseed meal enrichment of bread based on the richness of flaxseed with dietary fibre, protein, vitamins, and minerals. Carob fibre, inulin, and pea fibre addition to bread with respect to bread quality and dough performance was also studied (Wang et al. 2002). Dietary fibre enrichment has gained more importance in the prevention of cancer, cardiovascular diseases, and reduction of high cholesterol levels (Mesci et al., 2011). This health promoting effect may be caused by plenty of vitamins, minerals, dietary fibre, phytochemicals, and phytosterols found naturally in whole grains (Jonnalagadda et al., 2011).

Vegetable proteins (Bildstein et al., 2008; El-Adawy, 1997; El-Soukkary, 2001; Khalil, 2002; Seguchi and Abe, 2003; Seguchi et al., 2001, Skrbic and Filipcev, 2008) and animal proteins i.e. supplied from tench fish (Dursun et al., 2009) were used for protein enrichment in breads. The concept of the ideal protein provides that all amounts of essential amino acids are balanced against each other and the nonessential amino acids are according to the nutritional needs of the organism. Cereal proteins, on the other hand, are unbalanced in terms of essential amino acids and deficient in the essential amino acids lysine and threonine (Dhingra and Jood, 2002). Supplementing bread with protein concentrates and pure amino acids (i.e., lysine) can be nutritionally effective and shows great promise for improving the diet of people who depend on bread as their main source of nutrients (Pomeranz and Shellenberger, 1971).

The aims of this research are to investigate possibilities of using chicken meat (chicken meat and chicken meat powder) as an animal protein source in bread and determine the nutritional, sensory, and quality characteristics of those enriched breads. Therefore two types of flour, white wheat flour (type 650) and whole wheat flour were used in bread making studies.

MATERIAL AND METHODS

Materials

The white wheat flour and whole wheat flour were obtained from Yuksel Tezcan Gida Sanayi ve Ticaret A.S. (Izmir, Turkey). The chicken meat powder and chicken meat were supplied from Banvit A.S.(Balikesir, Turkey) and Keskinoglu Tavukculuk A.S.(Manisa, Turkey), respectively. The average particle size of white flour and chicken meat powder was 205 μm and 390 μm, respectively. Two types of baking improvers namely EMCE gluten plusP and Top Bake Pitta (ABP Mühlenchemie Gida San. ve Tic. A.S., Izmir, Turkey) with a rate of 0.4% (on flour basis) were blended with 70% whole wheat flour and 30% white flour to obtain whole wheat flour blend.

Methods

Chemical and technological properties of raw materials

The farinograph and extensograph analysis were conducted to examine the rheological properties of dough (ICC, 1992). The moisture (ICC, 1976), and ash contents of flour samples (ICC, 1990) were determined according to ICC Standard Methods. The protein content of the flour samples were measured according to the AACC method (AACC, 2000). The moisture, ash, and protein contents of chicken meat powder and chicken meat were analysed according to AOAC methods (AOAC, 1991; AOAC, 1996). All chemical analysis was carried out in triplicate and the mean value expressed as dry matter.

Bread making

Chicken meat powder (CMP) and chicken meat (CM) was added to the commercial type white wheat flour and whole wheat flour blend (containing 70% whole wheat flour, 30% white wheat flour, and 0.4% baking improvers). The chicken meat used in the study was first boiled in water until its cold point temperature exceeds 70 oC. Then skin is removed and meat is deboned and grounded into small pieces for 3 minutes in a blender (Waring Blender, Dynamics, New Hartford, Connecticut, USA). The bread formulations were optimized using the Detmold method with slight modifications (baking temperature and time) (AGF, 1978). For the bread making studies, chicken meat powder and chicken meat at 10, 15, 20, 25, and 30% levels (wet basis) were blended with flour samples. The amount of compressed yeast (3%) and salt (1.2%) used in these trials were calculated on the flour basis. After preliminary trials, two types of baking improver were used to improve the specific volume and the texture of the whole wheat breads. All the ingredients were mixed with an adequate quantity of water, which was determined according to the farinograph water absorption levels and kneaded in a spiral mixer (ISM-10, Inoksan, Bursa, Turkey) to get dough of a moderately stiff consistency. The dough was then placed in a fermentation chamber (FGM 100, Inoksan, Bursa, Turkey) for 30 min at 30 °C and 75% relative humidity. After manual aeration of the dough for 1 minute, the dough was then allowed to rest in the same fermentation chamber for 30 min and after this period they were divided into 400 g portions, and moulded in Teflon baking pans (bottom 80 x 80 mm, top 120 x 120 mm, and a height of 100 mm) and proved for 45 min. After the proofing period the breads were baked at 220 °C and 25% relative humidity in a preheated oven (FBE010, Inoksan, Bursa, Turkey) for 20 min and to avoid dryness of the bread crusts, some water being sprinkled on the pans manually immediately before baking. Loaves were removed from pans and subjected to a 4 hour cooling period at room temperature before performing of all analyses.

Bread analysis

All the breads were sliced into 12.5 mm thickness using a bread slicer prior to the measurements (Bosch Spot, Stuttgart, Germany). Crumb firmness was measured one day after baking with a texture analyzer, TA-XT2i (Stable Microsystems, Surrey, United Kingdom), equipped with a cylindrical probe of 36 mm in diameter at a speed of 1.7 mm/s according to AACC method 74-09 (AACC, 1988). Loaf volume was determined by the rapeseed displacement method (AACC, 2010). The sensory evaluations were conducted using ranking test with 30 randomly selected untrained panellists (Altug and Elmaci, 2005). The ranking test was scaled with “1” being the lowest score and “6” being the highest score. Five different sensory attributes, crumb colour and crust colour, crumb firmness and crust firmness, and overall acceptability, were assessed to determine the differences among samples using average panel scores. The water activity was measured in duplicate (AG400, Testo, Lenzkirch, Germany). The colour was measured in Hunter colour space using a ColorFlex colorimeter (HunterLab, Reston, Virginia, USA) where L is a measure of brightness (0: black, 100: white), +a/-a is a measure of redness/greenness, and +b/-b is yellowness/blueness. To reveal the overall effect of enrichment on colour total colour difference was calculated according to following formula;

StatisticalAnalysis

All data were analyzed with SPSS software version 16.0 (SPSS, 2007). One-way analysis of variance was used to compare the mean values and Duncan post hoc multiple comparison test was applied with a significance level of p<0.01 to evaluate the differences between the bread samples. The sensory analyses were evaluated using one-way analysis of variance and Tukey post hoc multiple comparison test with a significance level of p<0.01.

Results and Discussion

Evaluation of bread quality characteristics

The chemical composition and technological properties of raw materials and dough are given in Table 1. The water absorption of white wheat flour and whole wheat flour was found to be 66.1% and 71.1%, respectively by farinograph analysis and it is in agreement with the observation of Mis et al. (2012), which is also stating that dough extensibility can be predicted based on water absorption with its negative effect. For white wheat flour, development time was lower and stability was longer than whole wheat flour blend, these results were also in agreement with the study of Seyer and Gelinas (2009).

|

White wheat flour |

Whole wheat flour |

Chicken meat powder |

Chicken meat |

||

|

Moisture (%) |

11.94±0.27 |

9.80±0.31 |

2.20±0.57 |

64.67±0.13 |

|

|

Protein (%) |

12.13±0.11a,b |

10.39±0.31a,b |

78.83±1.77a,c |

84.83±3.33a,c |

|

|

Ash (%) |

0.62±0.02a |

1.67±0.03a |

11.15±1.65a |

2.89±0.01a |

|

|

Farinograph Results |

|||||

|

Water absorption (%) |

66.1 |

71.1* |

|||

|

Development time (min) |

1.4 |

5.5* |

|||

|

Stability (min) |

8.6 |

1.2* |

|||

|

Degree of softeningd |

100 |

70* |

|||

|

Extensograph resultse |

|||||

|

Resistance to extensiond |

1313 |

653* |

|||

|

Extensibilityd |

110 |

79* |

|||

|

Energy (cm2) |

158 |

71* |

|||

aExpressed on dry mater basis, b Nx5.7, c Nx6.25, d Brabender unit, e 135th minute result,*whole wheat flour blend

The physical and chemical properties of the bread samples are shown in Table 2. In the present study, the moisture content of the bread samples were between 35.5% and 42.9%. Similarly in another study, the moisture content of bread samples containing different levels of wheat germ and equal ratio of coarse and fine bran additions were found between 39.29% and 42.25% (Sidhu et al., 1999).

Loaf volume is a very important measure of bread quality (Shah et al., 2006). The level of enrichment and the type of flour significantly affected the specific volume of enriched breads (p<0.01). Bran has a negative effect on bread volume (Almeida et al., 2013; Ozboy and Koksel, 1999; Seyer and Gelinas, 2009; Zhang and Moore, 1999). White bread enriched with 10% chicken meat powder had a higher specific volume compared to the control sample. The similar results were obtained with Welsh onion powder enriched breads (Seguchi and Abe, 2003) and nut paste enriched breads (Oliete et al., 2008).

The addition of chicken meat and chicken meat powder increased the protein contents of the white and whole wheat bread samples (Table 2). Although the initial protein content of whole bread was higher than the white bread, the highest protein content was found for the 30% chicken meat powder enriched white bread.

Texture analysis results are shown in Table 2. There is no significant change in the firmness of enriched white bread samples containing chicken meat and chicken meat powder (p<0.01). For whole wheat breads, firmness was increasing with the increasing level of enrichment. Those samples which have lower specific volume also have higher crumb firmness in accordance with other studies (Shah et al., 2006; Jaekel et al., 2012)

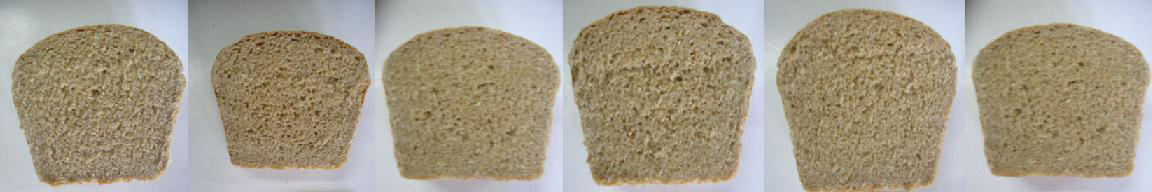

The effects of chicken meat powder and chicken meat on bread colour are given in Table 2. Total colour difference of bread crumbs whether they were produced from white flour or not, was significantly different from each other (p<0.01). Increasing levels of enrichment resulted in higher total colour differences. But the similar effect was not clear for the bread crusts. Also the crumb images are shown in Figure 1.

|

Specific volume (dm3/kg) |

Moisture (%) |

|||||||

|

Chicken (%)* |

A-CMP |

A-CM |

B-CMP |

B-CM |

A-CMP |

A-CM |

B-CMP |

B-CM |

|

0 |

2.700c |

2.700e |

2.015d |

2.015d |

39.835e |

39.835b,c |

36.235a |

36.235a |

|

10 |

2.965d |

2.555d,e |

1.975c,d |

1.705c |

35.455a |

39.305a,b |

40.260b |

36.600a |

|

15 |

2.660c |

2.360c,d |

1.905b,c |

1.635b,c |

36.115b |

39.095a |

40.700c |

38.740a |

|

20 |

2.300b |

2.445b,c |

1.890b,c |

1.625b,c |

38.520c |

38.930a |

41.610d |

38.310a |

|

25 |

1.890a |

2.090b |

1.830b |

1.545a,b |

39.440d |

40.115c |

42.195e |

41.215a |

|

30 |

1.800a |

1.860a |

1.735a |

1.425a |

40.625f |

41.515d |

42.815f |

41.470a |

|

Protein (%) |

Ash (%) |

|||||||

|

Chicken (%)* |

A-CMP |

A-CM |

B-CMP |

B-CM |

A-CMP |

A-CM |

B-CMP |

B-CM |

|

0 |

7.600a |

7.600a |

8.845a |

8.845a |

2.220a |

2.220b,c |

3.230a |

3.230a |

|

10 |

10.990b |

10.740a,b |

10.290a |

10.425a,b |

2.335a |

1.905a |

3.560a |

4.280b |

|

15 |

13.180b,c |

13.350b,c |

13.340b |

10.555a,b |

2.780a |

1.955a,b |

5.905b |

4.310b |

|

20 |

14.410c,d |

15.190c,d |

15.195c |

11.525b |

3.375a |

2.135a,b,c |

7.465c |

5.620c |

|

25 |

16.600d,e |

16.570c,d |

15.580c |

12.205b |

3.645a |

2.240c |

7.805c |

5.930c |

|

30 |

18.700e |

18.440d |

16.490c |

14.230c |

3.825a |

2.365c |

8.785c |

6.790d |

|

Crumb firmness (N) |

Water activity |

|||||||

|

Chicken (%)* |

A-CMP |

A-CM |

B-CMP |

B-CM |

A-CMP |

A-CM |

B-CMP |

B-CM |

|

0 |

9.304a |

9.304a |

26.838a |

26.838a |

0.952a |

0.952a |

0.960a |

0.960a |

|

10 |

10.514a |

9.225a |

28.431a |

29.126a,b |

0.967b |

0.971b |

0.971a,b |

0.996d |

|

15 |

9.851a |

9.080a |

34.391b |

30.596b,c |

0.971b |

0.978b,c |

0.977b,c |

0.989c,d |

|

20 |

10.856a |

9.841a |

34.746b |

31.665b,c |

0.982c |

0.979b,c |

0.984b,c |

0.980b,c |

|

25 |

10.597a |

10.366a |

40.035c |

33.238c,d |

0.984c |

0.983c |

0.984b,c |

0.975b |

|

30 |

10.411a |

10.742a |

40.421c |

36.317d |

0.990d |

0.994d |

0.990c |

0.981b,c |

|

∆E crumb |

∆E crust |

|||||||

|

Chicken (%)* |

A-CMP |

A-CM |

B-CMP |

B-CM |

A-CMP |

A-CM |

B-CMP |

B-CM |

|

0 |

- |

- |

- |

- |

- |

- |

- |

- |

|

10 |

7.000a |

2.903a |

1.795a |

3.103a |

12.180e |

4.083c |

1.868a |

4.198a |

|

15 |

9.670b |

3.073b |

2.030b |

3.480b |

11.350d |

3.318b |

4.103d |

4.868b |

|

20 |

10.500c |

3.108b |

4.080c |

4.503c |

7.580c |

2.418a |

3.313b |

5.530d |

|

25 |

14.350d |

4.880c |

4.565d |

4.703d |

5.680a |

13.288d |

3.755c |

4.888b |

|

30 |

16.175e |

8.840d |

5.130e |

5.318e |

5.950b |

14.800e |

5.478e |

5.373c |

*wet basis

A: white wheat flour bread, B: whole wheat flour blend bread, CMP: chicken meat powder, CM: chicken meat

a-f values in the same column followed by different superscripts are significantly different (p<0.01).

The effects of chicken meat and chicken meat powder on water activity are shown in Table 2. A significant increase in water activity was found with an increase in chicken meat and chicken meat powder (p<0.01). Similar increasing trend was observed in moisture of enriched breads as expected. Typically with those water activity results, the shelf life of the enriched breads would be no longer than 4-8 days depending on the storage conditions as it is stated by Cauvain and Young (2011), however the staling kinetics and microbial stability of enriched breads during storage should be determined in further studies.

Sensory evaluation

Table 3 represents the average scores of crumb colour, crust colour, crumb firmness, crust firmness and overall acceptability of enriched breads. Significant differences were obtained for crumb colour, crust colour, and crumb firmness and crust firmness with increasing levels of chicken meat and chicken meat powder (p<0.01). The overall acceptability of both breads was not perceived as significantly different (p>0.01), except for the whole wheat bread enriched with chicken meat. To reveal the clear interactions of sensory attributes with enrichment levels, further studies should be implemented in several different consumer groups.

|

Crumb colour |

Crust colour |

|||||||

|

Chicken (%)* |

A-CMP |

A-CM |

B-CMP |

B-CM |

A-CMP |

A-CM |

B-CMP |

B-CM |

|

0 |

1.00a |

1.40a |

2.40a |

2.50a |

1.00a |

1.70a |

1.45a |

1.25a |

|

10 |

2.00b |

2.25a,b |

3.00a,b |

2.50a |

2.15b |

2.25a |

2.80b |

2.55b |

|

15 |

3.35c |

2.80b |

3.30a,b |

3.20a,b |

3.30c |

2.30a |

3.90b,c |

4.05c |

|

20 |

3.75d |

4.25c |

3.80a,b |

3.50a,b,c |

3.80c |

4.40b |

4.05b,c |

4.15c |

|

25 |

5.05e |

5.10c |

3.85a,b |

4.35b,c |

5.15d |

4.85b,c |

4.35c |

4.35c |

|

30 |

5.85f |

5.20c |

4.65b |

4.95c |

5.60d |

5.50c |

4.45c |

4.65c |

|

Crumb firmness |

Crust firmness |

||||||||

|

Chicken (%)* |

A-CMP |

A-CM |

B-CMP |

B-CM |

A-CMP |

A-CM |

B-CMP |

B-CM |

|

|

0 |

1.70a |

2.05a |

2.90a |

2.30a |

1.45a |

2.85a |

2.95a |

2.60a |

|

|

10 |

2.20a,b |

2.70a,b |

3.30a |

2.85a,b |

3.00b |

3.05a,b |

3.40a |

3.40a |

|

|

15 |

2.95b,c |

3.60b,c |

3.30a |

3.40a,b |

3.00b |

3.10a,b |

3.40a |

3.50a |

|

|

20 |

3.90c,d |

3.80b,c |

3.65a |

3.65a,b |

3.80b,c |

3.40a,b |

3.55a |

3.65a |

|

|

25 |

4.70d,e |

4.35c |

3.65a |

4.40b |

4.70c |

3.95a,b |

3.80a |

3.85a |

|

|

30 |

5.55e |

4.50c |

4.20a |

4.40b |

5.05c |

4.65b |

3.90a |

4.00a |

|

|

Chicken (%)* |

Overall acceptability |

|||

|

0 |

A-CMP |

A-CM |

B-CMP |

B-CM |

|

10 |

3.00a |

2.60a |

2.70a |

2.15a |

|

15 |

3.05a |

3.30a |

2.80a |

3.35a,b |

|

20 |

3.15a |

3.45a |

3.20a |

3.70a,b |

|

25 |

3.80a |

3.60a |

3.85a |

3.75a,b |

|

30 |

4.00a |

3.70a |

4.05a |

4.00b |

|

4.00a |

4.35a |

4.40a |

4.05b |

|

*wet basis

A: white wheat flour bread, B: whole wheat flour blend bread, CMP: chicken meat powder, CM: chicken meat

a-f values in the same column followed by different superscripts are significantly different (p<0.01)

a) |

b) |

c) |

d) |

|

Figure 1. Crumb images of enriched breads with enrichment levels of 0-10-15-20-25-30% respectively (a)A-CMP, (b)A-CM, (c)B-CMP, (d)B-CM |

Conclusions

The results of this study has indicated that the bread with the addition of chicken meat powder and chicken meat had a potential to produce highly nutritional breads with respect to protein content as well as good consumer acceptance. Protein content of breads was increased nearly twofold for white breads for 30% level of enrichment, while it was increased more than fifty percent for whole wheat breads containing same amount of chicken. Compared to white bread samples, chicken meat powder and chicken meat addition caused an increase in crumb firmness of enriched whole wheat breads. Sensory characteristics of breads were significantly affected by the addition of chicken meat and chicken meat powder. However, for overall acceptability, no significant differences were detected. Development of these food types not only promotes the health of the general population, but it will also create a mainstream consumer demand for these types of functional foods. Further studies may focus on decreasing the moisture content of bread samples to increase shelf life and producing a new snack by drying of this bread.

АCKNOWLEDGEMENTS

This research is funded by The Scientific and Technological Research Council of Turkey (TUBITAK) with project no: 110-O-030 and Ege University Scientific Research Project Commission (BAP) with project no: 10-MUH-014. This research is a part of the MSc thesis of the author Hulya Cakmak.