THE INFLUENCE OF SILICA NANOPARTICLES ON MECHANICAL PROPERTIES OF POLYLACTIC ACID AS FOOD PACKAGING MATERIAL

ABSTRACT

INTRODUCTION

Packaging materials and technologies have been developed over the centuries, but today’s demands are looking for a new improvement and innovation [Bradley et all 2011]. The application of polymers in food packaging industry has increased enormously in the last decades. In the polymer global market, that has increased from 5 million tons in 1950's to nearly 100 million tons today, and the 42% is covered by packaging [Silvestre et. all 2011]. The recycling of conventional plastic food packaging materials is impractical; because of being food contaminated they are not totally recyclable and biodegradable. Recently, growing environmental awareness followed by possible lack of fossil fuels has led to new packaging material trends: sustainability, eco-efficiency and biodegradability. Polylactic acid (PLA) is typical linear aliphatic polyester. It is one of the most popular commercial biodegradable materials since it is biodegradable, nontoxic to the human body, and to environment, and it is produced from renewable resources. It can be processed by injection moulding, film extrusion, blow moulding, thermoforming, fibre spinning and film forming [Rasal et.al. 2010]. However, some of its properties are not satisfactory for application especially in food packaging [Wen et.al. 2011, Jamshidian et.al.2010; Dorigato et.al.2012; Sanches-Garcia et.al. 2010; Lagaron et.al. 2011]. Polymer nanotechnology is a broad interdisciplinary area of research that can provide innovative solutions to improve the performances of bio-polymers further adding safety, economical and environmental advantages [Pilic 2012]. Inorganic fillers as dispersed phase in nanocomposites are characterized with at least one dimension in nanomether scale. Due to their small particle size and high surface area, nanoparticle can create interfaces with polymer matrix improving their mechanical and thermal properties. PLA /nanocomposites reperesent one of the most promising material for the future research [Duncan 2011]. Currently PLA is used in food packaging application only for the short shelf-life products. For this reason, it is very important to understand the stability of PLA under realistic conditions of food packaging, in order to match with the shelf-life of foodstuff [Ahmed et.al. 2010].

The aim of this work was to investigate the influence of different silica nanoparticles on the mechanical properties of PLA polymer matrix with potential use as food packaging material. It was determined that only very low silica content (0.05 wt. %) increased mechanical properties of PLA polymer matrix.

MATERIAL AND METHODS

The PLA used in this study was provided by Symbra Technology, Netherlands. The molecular weight of PLA was determined at temperature 25°C by gel permeation chromatography (GPC) using Agilent 1100 Series system with refractive index, RID 1200, and diode array 1200 detectors. The column ZORBAX PSM 300 was used. The rate flow of the eluent tetrahydrofuran was 1 cm3min–1. The average molar masses (Mn, Mw) and polydispersity index (Q) were determined using software Agilent ChemStation. Poly (styrene) standards were used for the calibration curve. Parameters of the neat PLA from (GPC) are: Mn=60520; weight-average molecular weight Mw=160780 and polydispersity of Q=2.6. The nanosilica Sidistar T120 with specific surface 20 m2/g and average particle size 150nm and type N999 with specific surface 45-60 m2/g and average particle size 40nm were supplied by Elkem (Oslo, Norway); they were used as received.

Sample preparation

Neat PLA and PLA films with different weight content of nanosilica (from 0 to 2 wt. %) were prepared by solution casting method in chloroform. Silica was added in chloroform and stirred in ultrasonic bath for 10 min. Nanoparticles were dispersed in the solvent using ultrasonic bath. Then PLA was added to solvent/silica mixture and stirred with magnetic bar for 4 h hours at 40°C. After dissolving in chloroform, PLA/silica nanocomposites were poured into glass Petri dishes (10 cm diameter) and vacuum dried for 2h and, additionally, 24 hours for total evaporation of solvent at room temperature.

Characterization

Tensile strength and elongation at break were measured on instron dynamometer Toyoseiki AT-L-118A. All samples were prepared and measured according to the ASTM D638 standard.

Results and Discussion

Table 1 shows the values of tensile strength of PLA hybrid materials prepared using two type of nanosilica (T120 and N999). Mechanical properties of prepared nanocomposites were improved only by addition of 0.05 wt.% of silica (for both types). The value of tensile strength for PLA nanocomposite with 0.05% of silica T120 showed notably increase. However the addition of 0.05 wt. % of silica N999 caused only slight increase in tensile strength in comparison to neat PLA matrix. It was found that there was no influence of lower silica content (0.02 wt. %) on the mechanical performance of PLA matrix. A decreasing of tensile strength is affected by higher silica content. Increasing T120 silica content from 0.1 wt.% to 1 wt.% the value of tensile strength of PLA hybrid materials has decreased in regard to the one of neat PLA, and for the sample with 2 wt. % of silica, the value was under the one of pure PLA. The addition of silica N999 (from 0.1 wt. % to 1 wt. %) caused lower values of tensile strength compared to the ones of neat PLA and significant reduction of mechanical properties for PLA containing 2 wt.% of N999 silica. The decrease of tensile properties with addition of 2 wt. % of silica nanofillers (both used types) could be explained by formation of agglomerates.

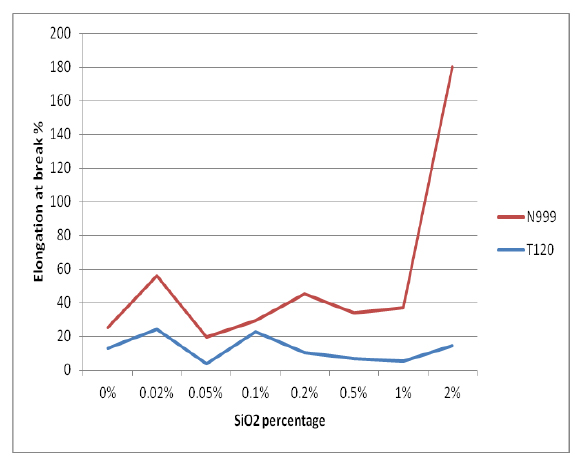

The influence of different silica type and content on the values of elongation at break of PLA film is shown in figure 2. It could be noticed that there is no observed significant trend of the effect of nanoparticles addition on the elongation at break. The addition of T120 silica content causes the variation of the studied mechanical performances from 3.5 to 22.75 On the other hand significant increase of elongation at break was found for PLA containing higher N999 content than 1wt.%

Addition of fumed silica nanoparticles improved mechanical properties only for small percentage of nanoparticles. This result is probably due to achievement of good dispersion only for low particles content in polymer matrix. On the other hand, decrease of tensile strength with addition of higher nanoparticles content is probably due to agglomerate formation [Radusin et.al. 2012]

% SiO2 |

Rm [MPa] T120 |

Standard deviation(σ) [MPa] |

Rm[MPa] N999 |

Standard deviation(σ) [MPa] |

|

0% |

47 |

2.8 |

47 |

2.8 |

|

0.02% |

45 |

1.4 |

47 |

5.7 |

|

0.05% |

51 |

2.3 |

48 |

4.8 |

|

0.1% |

47 |

0.7 |

42 |

3.6 |

|

0.2% |

44 |

5.3 |

42 |

3.5 |

|

0.5% |

47 |

4.8 |

47 |

3.7 |

|

1% |

47 |

3.9 |

41 |

3.6 |

|

2% |

43 |

1.5 |

33 |

0.5 |

Fig. 1. The influence of different silica type and content on the elongation at break of obtained PLA nanocomposites

Fig. 1. The influence of different silica type and content on the elongation at break of obtained PLA nanocompositesCONCLUSIONS

In this work two series of PLA hybrid materials with different silica types (T120 and N999) were prepared using solution casting method in chloroform and varying the nanofiller content (from 0 to 2 wt. %). Two types of silica nanoparticles have different influence on the characteristics of the same PLA matrix. The addition of 0.05 wt. % of T120 and N999 silica nanofillers improved mechanical properties, due to their good dispersion in PLA matrix. Increasing silica content, the tensile strength and elongation at break were decreased. Obtained results could be further used for future research in the field of PLA/silica nanocomposites, as important materials due to their good and satisfying mechanical properties for food packaging application.

АCKNOWLEDGEMENTS

This paper is a result of the research within the project III46001 “Development and utilization of novel and traditional technologies in production of competitive food products with added value for national and global market - CREATING WEALTH FROM THE WEALTH OF SERBIA”, financed by the Ministry of Education and Science, Republic of Serbia.