RELATION BETWEEN ANTIOXIDANT ACTIVITY OF AFFINED C SUGAR AND THERMALY INDUCEDNONENZYMATIC BROWNING

DOI:

UDK:

JOURNAL No:

Volume 38, Issue 2

PAGES

79-85

KEYWORDS

affined C sugar; antioxidant activity; nonenzymatic browning

Aleksandra Č. Mišan1, Julianna F. Gyura2, Marijana B. Sakač1, Dragana M. Simović-Šoronja2,

Zita I. Šereš2, Biljana S.Pajin2

Zita I. Šereš2, Biljana S.Pajin2

1Institute of Food Technology, University of Novi Sad, Bul. cara Lazara 1, 21000 Novi Sad, Serbia

2Faculty of Technology, University of Novi Sad, Bul. cara Lazara 1, 21000 Novi Sad, Serbia

2Faculty of Technology, University of Novi Sad, Bul. cara Lazara 1, 21000 Novi Sad, Serbia

ABSTRACT

ABSTRACT

Affined C sugar was obtained at the third stage of crystallization from the process of sugar production and was characterized by 99.82% dry matter (DM) content, 97.6 °Z sucrose content, pH=6.81, 20366 IJ/DM coloured matter content measured at 420 nm and 4673 IJ/DM coloured matter content measured at 560 nm. As the development of coloured compounds and Maillard reaction products is favoured by the increase in temperature, the aim of this study was to investigate the relation between thermally induced nonenzymatic browning and antioxidant activity of affined C sugar. Nonenzymatic browning was tested by incubating 50 g of 40°Bx affined C sugar solution at 70 °C, 80 °C and 90 °C for 1200 min. Thermal treatment resulted in the increase in coloured substances content. Incubation at 90 °C for 1200 min resulted in partial sucrose degradation, which was followed by the increase in fructose and glucose content. Scavenging activity against DPPH radicals (DPPH˙) decreased with the increase in the incubation temperature. Since the antioxidant activity of Maillard reaction products was reported, our results indicate that Maillard reaction may not have been the main mechanism of nonenzymatic browning. Further research needs to be done in order to characterize the antioxidants in affined C sugar and the products of browning reaction under the described experimental conditions.

INTRODUCTION

Colour of the final product is a key quality measurement in sugar industry. While the nature of colouring substances in sugarcane processing was well studied and documen-ted (Bento and Sá, 1998), colour formation in sugar beet manufacture is not much examined and understood. Because of that, it is not possible to predict the content of coloured substances in the final product on the basis of raw material chemical compo-sition.

Coloured substances are formed during sugar beet processing as a result of pH changes, and thermal and autocatalytic

effects (Šereš et al., 2004; Gyura et al., 2005). These impurities are of high mole-cular masses, polymeric and with tendency to occlude within the sugar crystal (Coca et al., 2008). Maillard reaction and alkaline de-gradation of invert sugars have been con-sidered to be the main mechanisms of co-lour formation during purification stage (Co-ca et al., 2008). Melanoidins as Maillard reaction products are formed by the reaction of monosaccharides and carbonyl com-pounds with amino acids and are recogni-zed as acidic and polymeric compounds with a highly complicated structure (Cä-mmerer and Kroh, 1995; Cämmerer et al., 2002).

Coloured substances are formed during sugar beet processing as a result of pH changes, and thermal and autocatalytic

effects (Šereš et al., 2004; Gyura et al., 2005). These impurities are of high mole-cular masses, polymeric and with tendency to occlude within the sugar crystal (Coca et al., 2008). Maillard reaction and alkaline de-gradation of invert sugars have been con-sidered to be the main mechanisms of co-lour formation during purification stage (Co-ca et al., 2008). Melanoidins as Maillard reaction products are formed by the reaction of monosaccharides and carbonyl com-pounds with amino acids and are recogni-zed as acidic and polymeric compounds with a highly complicated structure (Cä-mmerer and Kroh, 1995; Cämmerer et al., 2002).

According to Heitz (1995), up to 80% of co-lour in sugar beet juice is a result of alkaline degradation of hexoses (HADP). The pro-duction of coloured HADP takes place at the common pH of a beet sugar factory (8–11) while the formation of degradation products mainly occurs in the purification step where temperature increases up to 85 °C and pH rises up to strong basic values (11–12). The nature and structure of coloured HADP have not been elucidated but they are probably formed due to the extensive aldolisation of intermediate di-carbonyl com-pounds in alkaline solutions (de Bruijn, 1986). Coloured substances formed through sugar beet processing negatively influence the quality of white sugar. However, Maillard reaction compounds have been reported to possess antioxidant activity (Yanagimoto et al., 2002; Yanagimoto et al., 2004). Payet et al. (2005) reported the antioxidant activity of cane brown sugars, which was attributed to the presence of polyphenol compounds and Maillard reaction products. As the concen-tration of nitrogen compounds in sugar beet juices is higher than in cane sugar juices, Coca et al. (2004) assume that the for-mation of melanoidins in sugar beet proce-ssing is more intensive.

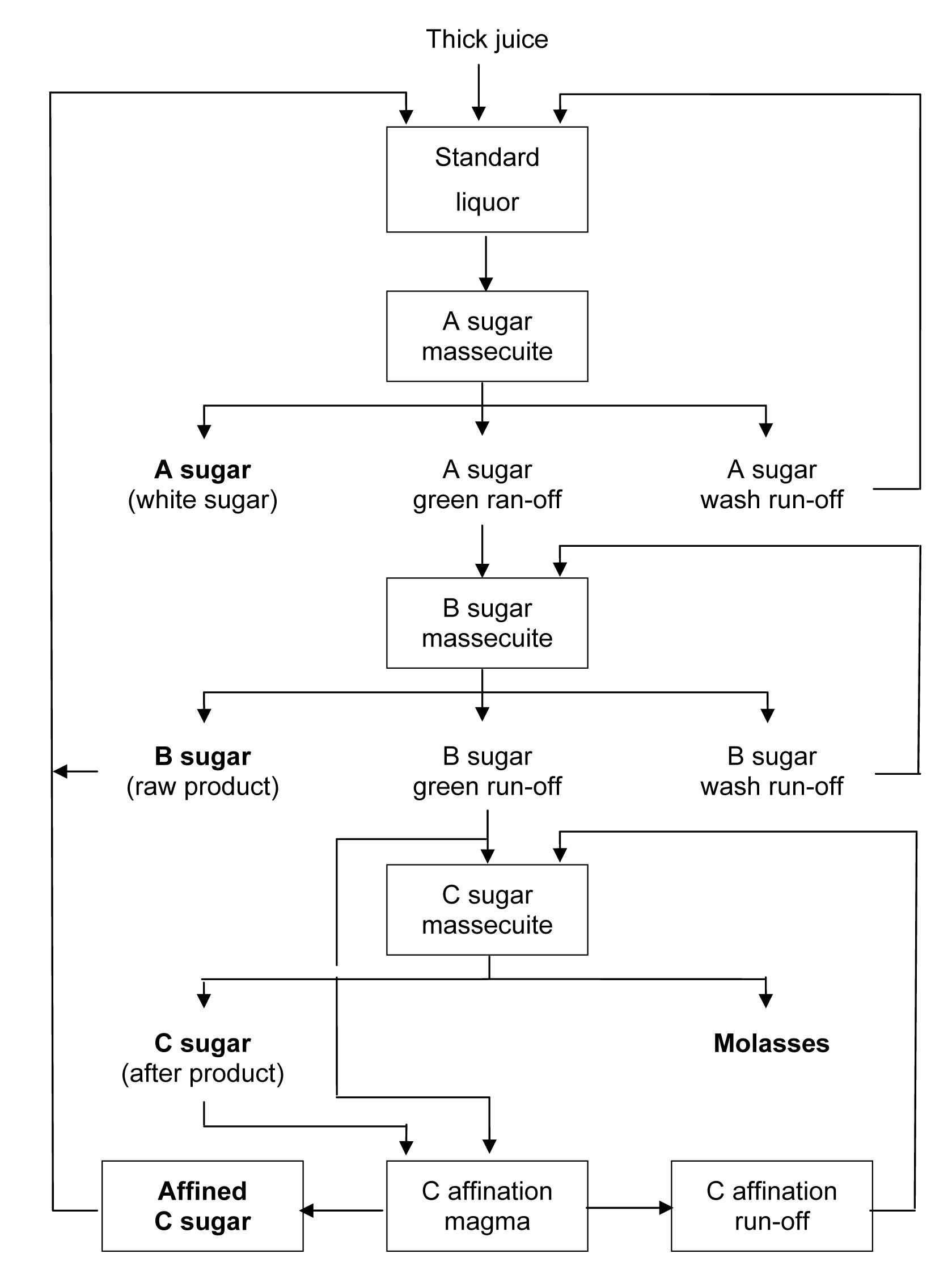

Affined C sugar is an intermediate product of the three-stage crystallization process in sugar beet processing (Figure 1). From the third stage of crystallization, affined C sugar is directed to the first crystallization stage, and in this way directly influences the qua-lity of the final product - white sugar. Since the development of coloured compounds and Maillard reaction products is favoured by the increase in temperature, the aim of this study was to investigate the relation between thermally induced nonenzymatic browning and antioxidant activity of affined C sugar.

Affined C sugar is an intermediate product of the three-stage crystallization process in sugar beet processing (Figure 1). From the third stage of crystallization, affined C sugar is directed to the first crystallization stage, and in this way directly influences the qua-lity of the final product - white sugar. Since the development of coloured compounds and Maillard reaction products is favoured by the increase in temperature, the aim of this study was to investigate the relation between thermally induced nonenzymatic browning and antioxidant activity of affined C sugar.

MATERIALS AND METHODS

Materials

Affined C sugar was obtained at the third stage of crystallization from the process of sugar production. The basic characteristics of the affined C sugar were determined according to the methods specified by Rei-nefeld and Schneider (1978).

Thermally induced nonenzymatic browning

Affined C sugar was dissolved in distilled water and diluted to 40°Bx dry matter (con-trol). Nonenzymatic browning was tested by incubating 50 g of affined C sugar solution (40°Bx dry matter) at 70 °C, 80 °C and 90 °C in water bath with the precision of ± 0.02 °C for 1200 min.

Thermally induced nonenzymatic browning

Affined C sugar was dissolved in distilled water and diluted to 40°Bx dry matter (con-trol). Nonenzymatic browning was tested by incubating 50 g of affined C sugar solution (40°Bx dry matter) at 70 °C, 80 °C and 90 °C in water bath with the precision of ± 0.02 °C for 1200 min.

HPLC determination of fructose, glucose, raffinose and sucrose

A high-performance liquid chromatographic (HPLC) method was applied to determine fructose, glucose, raffinose and sucrose content of affined C sugar solutions. The HPLC (HP 1090, Hewlett-Packard, USA) system consisted of a Zorbax Carbohydrate 4.6 × 250 mm, 5 μm column (Agilent Technologies), a solvent system of acetone-trile/water, 70/25 (v/v), a flow rate of 1 mL/min, a refractive index detector ope-rating in the range od 4 × 10-5 RIU, and at the temperature of 35 °C. Prior to injection, all samples were diluted in deionised water and filtered through a 0.45 μm Rotilabo-Spritzenfilter CME (Carl Roth).

Scavenging activity against DPPH˙of affined C sugar

Affined C sugar was dissolved in deionized water, in an appropriate manner to obtain a series of concentrations. Scavenging acti-vity against the stable DPPH˙ (1,1-diphenyl-2-picryl-hydrazyl radicals) was determined spectrophotometrically following the proce-dure of Espin and others (2000). The IC50 (mg/mL) was defined as the mass concen-tration of an antioxidant solution which was required to quench 50% of the initial DPPH˙ under the given experimental conditions. It was obtained by interpolation from linear regression analysis.

RESULTS AND DISCUSSION

Basic quality parameters of affined C sugar are presented in Table 1. The obtained va-lues are as expected for that type of an intermediate product. The contents of su-crose, fructose, glucose and raffinose in control and thermally treated solutions of affined C sugar diluted to 40°Bx dry matter were presented in Table 2.

Table 1. Basic quality parameters of affined C sugar

Dry matter (%) |

99.82 |

|

Content of sucrose (°Z) |

97.6 |

|

pH value |

6.81 |

|

Content of coloured matter at 420 nm (IJ/DM) |

20366 |

|

Content of coloured matter at 560 nm (IJ/DM) |

4673 |

Table 2.content of sucrose, fructose, glucose and raffinose in thermally treated solutions of 40° Bx affined C

sugar

sugar

Sample |

Sucrose |

Fructose (mg/mL) |

Glucose (mg/mL) |

Raffinose (mg/mL) |

|

C 40 Bx |

471.9 ± 1.68 |

0.97 ± 0.11 |

1.01 ± 0.20 |

2.10 ± 0.25 |

|

C 40 Bx 70 °C |

557.1 ± 1.24 |

1.75 ± 0.18 |

2.23 ± 0.45 |

2.31 ± 0.18 |

|

C 40 Bx 80 °C |

565.6 ± 1.32 |

1.86 ± 0.14 |

2.24 ± 0.32 |

2.59 ± 0.23 |

|

C 40 Bx 90 °C |

549.1 ± 1.45 |

12.15 ± 0.16 |

15.52 ± 0.65 |

2.31 ± 0.24 |

Values are means of three determinations ± standard deviation.

Table 3.Scavenging activity against DPPH˙of thermally treated solutions of 40°Bx affined C sugar solution

Sample |

DPPH˙ scavenging activity |

|

C sugar |

0.440 ± 0.026 |

|

C sugar at 70 °C |

0.644 ± 0.114 |

|

C sugar at 80 °C |

1.613 ± 0.236 |

|

C sugar at 90 °C |

4.010 ± 0.179 |

Values are means of three determinations ± standard deviation.

As it can be seen in Table 2, the content of sucrose, glucose and fructose slightly in-creased as a result of the incubation at 70 and 80 °C. Those results can be explained by the reduction of solvent volume during the incubation. However, 1200 min incuba-tion at 90 °C resulted in partial sucrose de-gradation, which was followed by the in-crease in fructose and glucose content. Raffinose was present in all of the invest-tigated solutions in the concentration which was not affected by the thermal treatment.

As the thermal treatment resulted in the in-crease in coloured substances content, which was measured as an increase in absorbance at 420 and 560 nm (data not shown), we decided to evaluate the antioxi-dant activity of thermally treated affined C sugar solutions. Scavenging activity against DPPH˙ test was chosen as it is one of the most frequently used and most convenient tests. The results of scavenging activity against DPPH˙of investigated solutions are presented in Table 3.

Development of Maillard reaction products is favoured by the increase in temperature, and considering that the antioxidant activity of Maillard reaction products was reported (Yanagimoto et al., 2002; Yanagimoto et al., 2004), the increase in antioxidant activity was expected. However, referring to the results shown in Table 3, scavenging ac-tivity on DPPH˙ decreased with the in-crease in the incubation temperature (higher IC50 value indicates lower scavenging acti-vity on DPPH˙). The decrease in antioxi-dant activity, attributed to the action of Maillard reaction products, indicated that Maillard reaction may not have been the only mechanism of nonenzymatic browning. Further research needs to be done in order to characterize the antioxidants in affined C sugar and the products of browning reaction under the described experimental conditi-ons.

As the thermal treatment resulted in the in-crease in coloured substances content, which was measured as an increase in absorbance at 420 and 560 nm (data not shown), we decided to evaluate the antioxi-dant activity of thermally treated affined C sugar solutions. Scavenging activity against DPPH˙ test was chosen as it is one of the most frequently used and most convenient tests. The results of scavenging activity against DPPH˙of investigated solutions are presented in Table 3.

Development of Maillard reaction products is favoured by the increase in temperature, and considering that the antioxidant activity of Maillard reaction products was reported (Yanagimoto et al., 2002; Yanagimoto et al., 2004), the increase in antioxidant activity was expected. However, referring to the results shown in Table 3, scavenging ac-tivity on DPPH˙ decreased with the in-crease in the incubation temperature (higher IC50 value indicates lower scavenging acti-vity on DPPH˙). The decrease in antioxi-dant activity, attributed to the action of Maillard reaction products, indicated that Maillard reaction may not have been the only mechanism of nonenzymatic browning. Further research needs to be done in order to characterize the antioxidants in affined C sugar and the products of browning reaction under the described experimental conditi-ons.

CONCLUSIONS

Prolonged incubation of affined C sugar so-lution at 90 °C induced sucrose degrada-tion, which was followed by the increase in glucose and fructose content. Thermal treat-ment of affined C sugar favoured the forma-tion of coloured substances and was, at the same time, followed by the decrease in anti-oxidant activity.

ACKNOWLEDGMENTS

This work was supported by the Project No TR-31014, Ministry of Education and Scien-ce, Republic of Serbia.