Effects of addition of carp meat on hardness of rat feed pellets

ABSTRACT

Introduction

Pelleting process denotes process in which powder or bulk material is compressed into the granules (usually cylindrically shaped). Pelleting process is nowadays almost inevitable phase in various processes, such as food and animal feed production, chemical industry, metallurgy, energetics, etc. It was introduced in animal feed production at the beginning of 20th century (Behnke, 2001). Although, process of pelleting of animal feed raises overall production costs, it is accepted as a standard phase, especially in poultry feed production process, due to its beneficial effects on quality of the final product: decrease of product loss, reduction of selective intake of feed, increase of feed consumption, increase of feed digestibility, increase of feed conversion, increase of flowability of the product, reduction of transporting costs, etc (Čolović et al., 2010).

Pelleting process can be considered as a causal relationship of physical and chemical characteristics of raw materials, process parameters, system parameters and functional characteristics of macronutrients on nutritional, hygienic, and physical quality of pellets (Briggs et al., 1999; Thomas et al., 1997). Diet composition is usually influenced by animal’s nutritional demands. However, selection of ingredients is more or less flexible, and it is driven by availability and price of specific components and technological influence of the component on quality of pellets. Usage of ingredients with negative influence on binding of particles can lead to production of pellets with bad quality (Thomas et al., 1996; Vukmirović et al., 2010).

Although pelleted diets are usually fed to poultry and swine, other groups of animals, as experimental rodents, also require pelleted feed. Rats are opportunistic omnivores, which mean that they can consume wide range of ingredients, such as seeds, nuts, grains, vegetables, fruits, meats, and invertebrates. Rats prefer starch and protein rich foods, but they are also partially predatory. Feed wastage and feed intake of rats can be reduced when mash rather than pelleted diets were fed. Therefore, usage of pelleted feed is advisable for feeding of rats (Ford, 1977).

The aim of this research was to investigate effect of addition of carp meat on hardness of experimental rat feed pellets.

MATERIAL AND METHODS

Materials

Procedure for preparation of rat feed

Five groups of pelleted rat feed were used in this experiment. Groups were differing in quality of carp meat which was used in preparation of diets. Carp feeding experiment, from which carp meat was taken, was based on investigation of effects of different oil sources on fish meat quality. Five different oils and oil blends were used in carp feeding experiment: soybean oil (group 1), linseed oil (group 2), blend of linseed oil, arachidonic acid (ARA) and docosahexaenoic acid (DHA) (group 3), fish oil (group 4), and blend of fish oil and arachidonic acid (ARA) (group 5). After the carp feeding experiment, carp was sliced in fillets and fillets were frozen. Frozen carp fillets were grinded on a grinding machine and obtained “soft pasta” was mixed with corn flake in the ratio 7.5 kg of fish meat and 2.6 kg of corn flake. The obtained pre-mixture was dryied by air ventilation at room temperature till 86 % of dry matter content was reached, and then mixed with standard rat feed components in the ratio 5:20. Diet formulation is shown in Table 1.

|

Ingredient |

% |

|

Corn |

16.00 |

|

Rye |

9.60 |

|

Extracted soybean meal (46% of protein) |

13.60 |

|

Extracted sunflower meal (34% of protein) |

6.40 |

|

Corn gluten |

3.60 |

|

Fish meal from carp fillets |

20.00 |

|

Wheat meal |

26.31 |

|

Calcium carbonate |

0.96 |

|

Vitamin E |

0.0056 |

|

Monocalcium phosphate |

0.32 |

|

Sodium chloride |

0.32 |

|

Adsorbent |

2.40 |

|

Premix |

0.46 |

Experimental rat feed diets were pelleted on a small-scale ring die pellet press. Diameter of rat feed pellets was set to be 12 mm.

Rat feed pellets texture measurement

For texture measurement of pelleted rat feed texture analyser (Lloyd 1000 R Material Testing Machines, UK) was used (Figure 1). The machine records data during measurement, and draws the load – extension curve (compressive force and displacement connection), expressed in [mm] on the X axis and in [N] on the Y axis.

Pelleted rat feed samples were examined in two positions: vertical and horizontal (Figure 2).

Parameters of texture analyser were:

- Test type: compression;

- Load cell: 1 kN;

- Speed: 10.00 mm/min

- Y axis: 1000 N

- X axis: 5 mm

StatisticalAnalysis

All data were analysed with Statistica software version 10.0 (StatSoft, 2011). One-way analysis of variance was used to compare the mean values and Tukey post hoc multiple comparison test was applied with a significance level of p<0.05 to evaluate the differences between the samples.

Results and Discussion

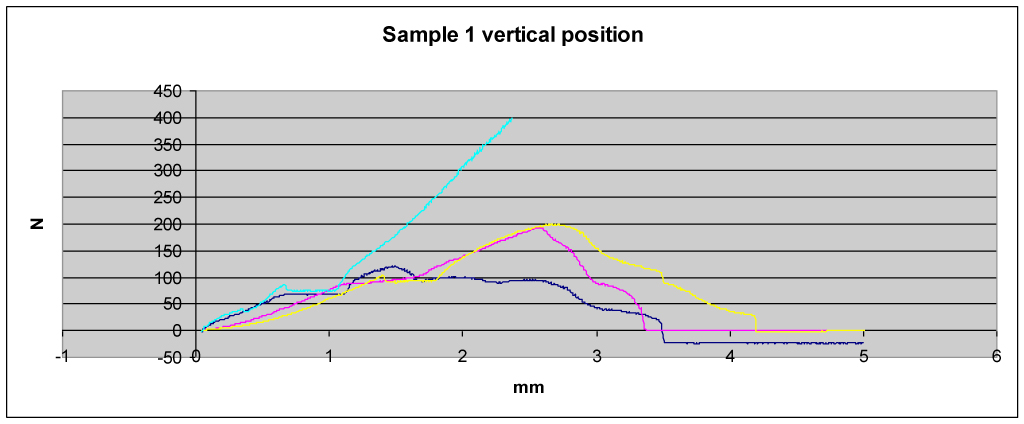

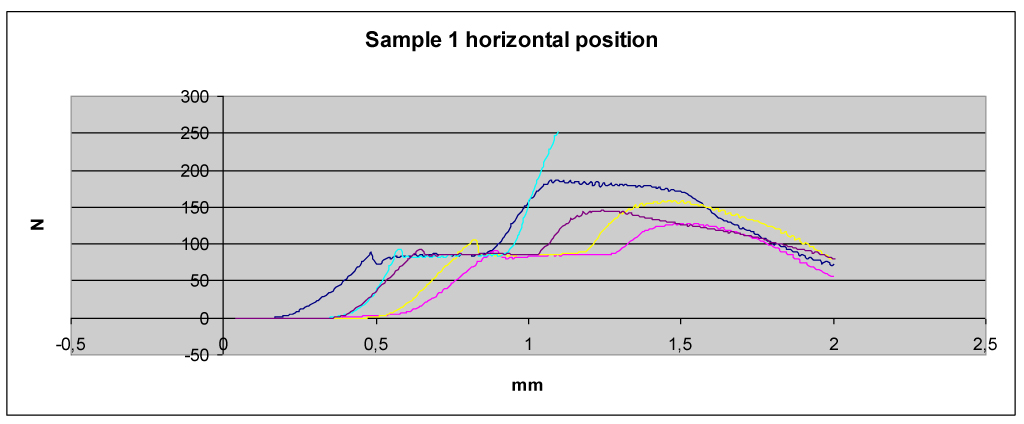

From the load – extension curves maximum braking forces were read. Breaking forces of sample 1 (soybean oil) in vertical and horizontal position are shown in Figure 3 and 4. Average value of maximum breaking force for pellets in vertical position was 172.03 N, while standard deviation of the measurements was 43.74 N. Average value of maximum breaking force for pellets from the same group in horizontal position was 155.06 N, while standard deviation of the measurements was 25.09 N.

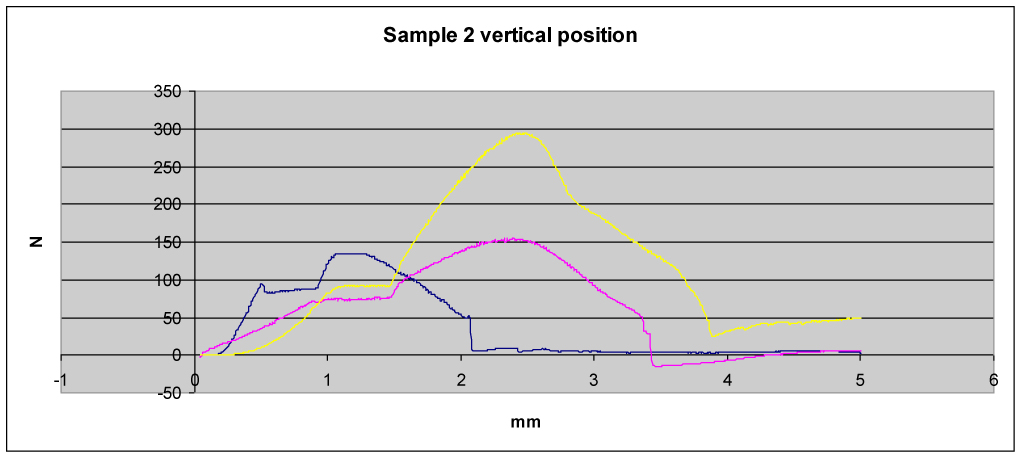

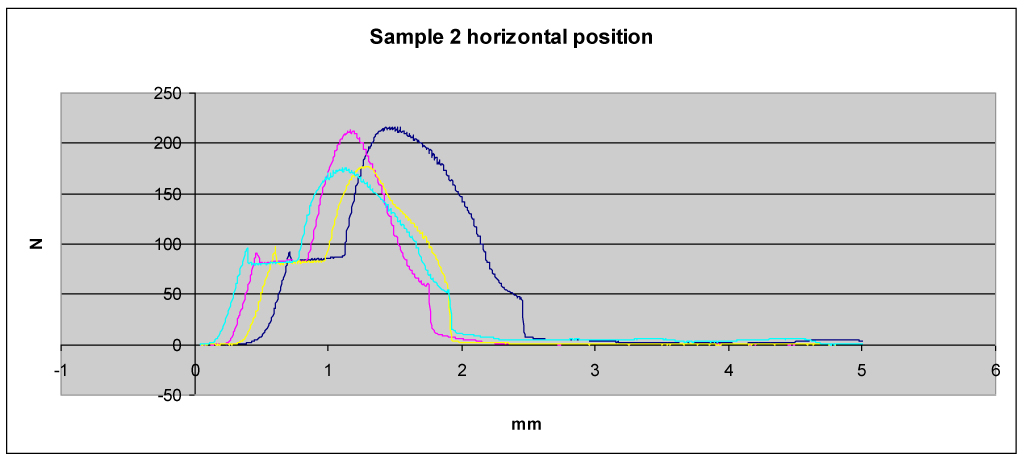

In Figures 5 and 6 breaking forces for sample 2 (linseed oil) in vertical and horizontal position are shown. Average value of maximum breaking force for pellets in vertical position was slightly higher when compared with sample 1 and it was 208.56 N, while standard deviation of the measurements was 30.26 N. Likewise, average value of maximum breaking force for pellets in horizontal position (195.59 ± 22.40 N) was higher when compared with sample 1.

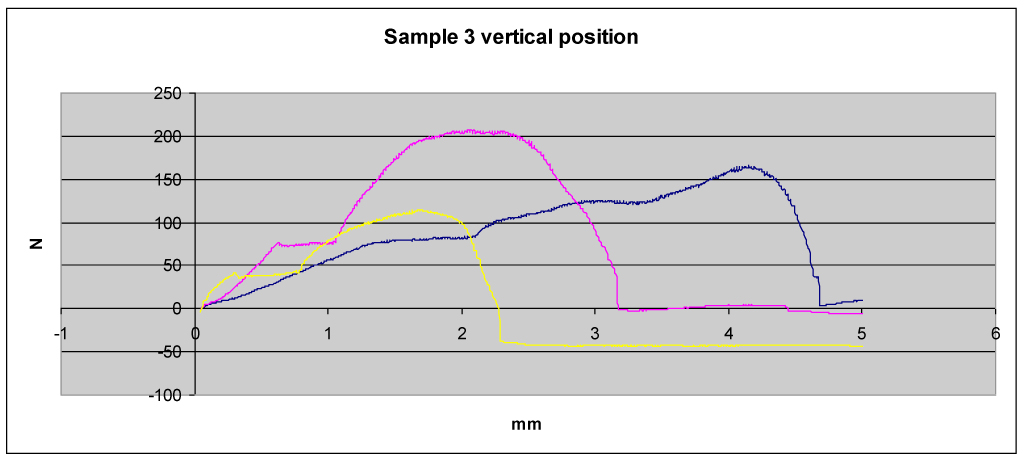

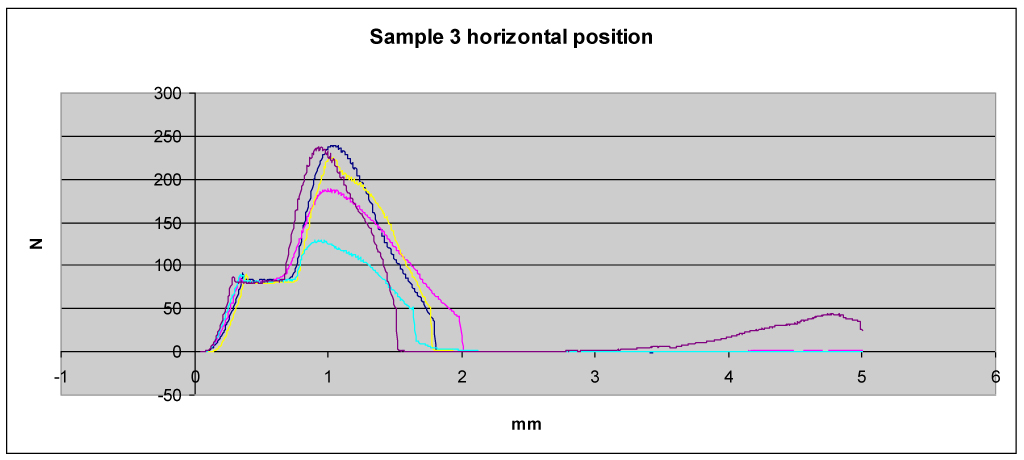

Breaking forces for sample 3 (blend of linseed oil, ARA and DHA) in vertical and horizontal position are shown in Figures 7 and 8. Average value of maximum breaking force for pellets in vertical position was 162.37 ± 46.42 N, while average value of maximum breaking force for pellets in horizontal position was 204.23 ± 46.31 N.

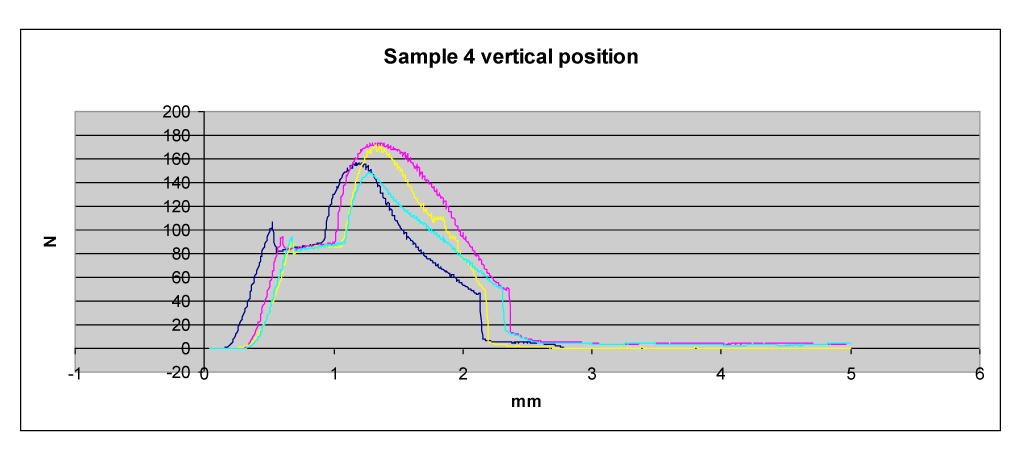

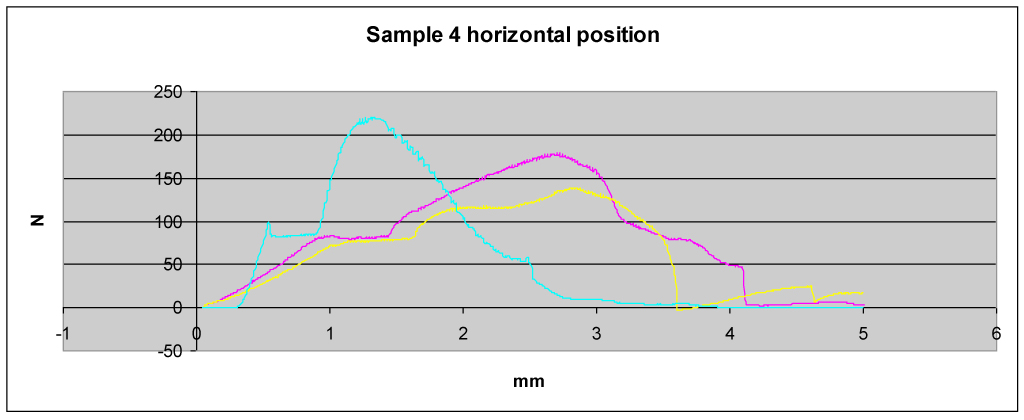

In Figures 9 and 10 breaking forces for sample 4 (fish oil) in vertical and horizontal position are shown. Average value of maximum breaking force for pellets in vertical position was 162.97 ± 12.52 N, while average value of maximum breaking force for pellets in horizontal position was 179.66 ± 40.81 N.

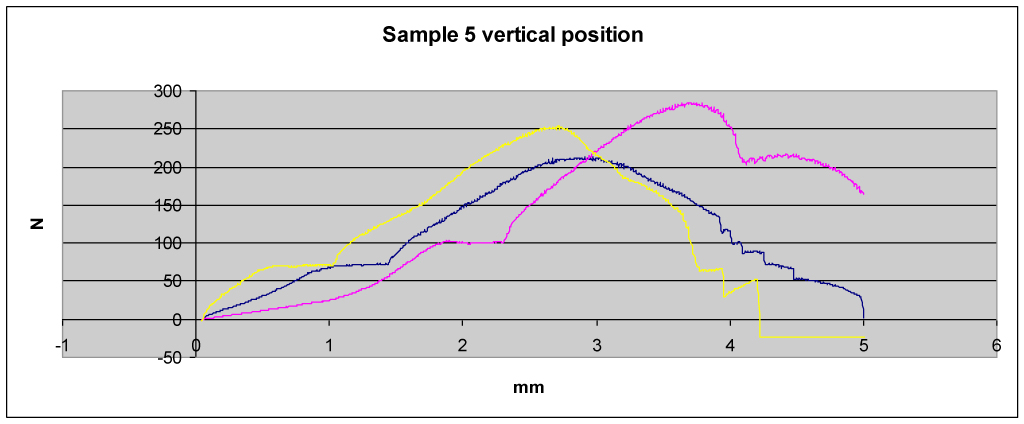

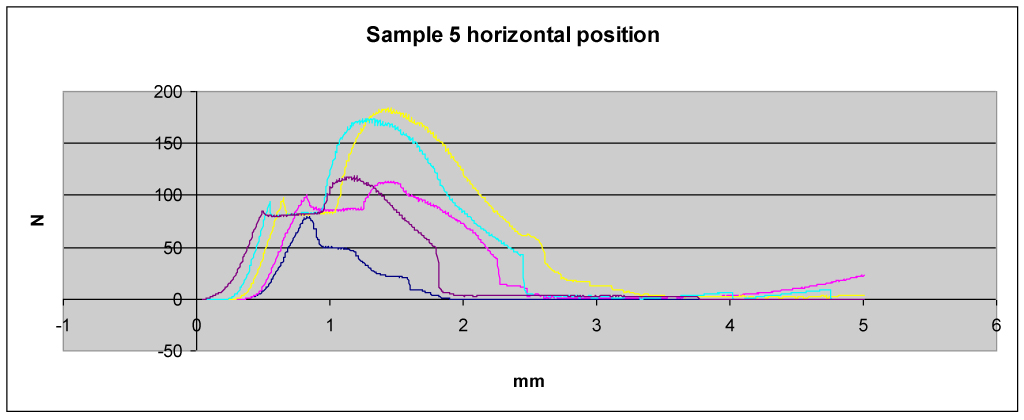

Breaking forces for sample 5 (blend of fish oil and ARA) in vertical and horizontal position are shown in figures 11 and 12. Average value of maximum breaking force for pelleted sample 5 in vertical position was 250.24 ± 35.40 N, while average value of maximum breaking force for pelleted sample 5 in horizontal position was 133.96 ± 43.81 N.

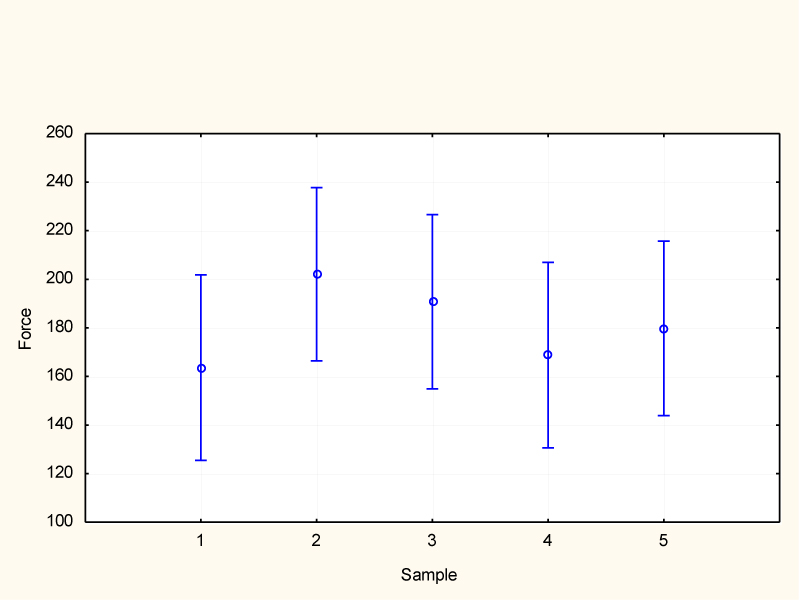

Results of one-way analysis of variance, which was used to compare the mean values of breaking forces, are shown in Figure 13. Although there was a difference between mean values of the samples, ANOVA analysis showed that there were no significant differences between five different samples at 95% probability level.

Conclusions

From the results of this study can be concluded that variation of meat of carp fed with different oil sources, which was added in experimental rat feed, did not have significant influence on breaking force of rat feed pellets. It seems that oil source did not change carp meat pelletizing characteristics.

АCKNOWLEDGEMENTS

This work has been co-financed by the European Union through project HUSRB-1002-214-120 (“Research cooperation on developing innovative fish feed for promotion of healthy food in the region”) within the Hungary-Serbia IPA Cross-border Co-operation Programme.

JOURNAL TOOLS

JOURNAL TOOLS

INSTITUTE

INSTITUTE